Coal Feeder Conveyor Belt

Get Price Quote

We deal in Coal Feeder Conveyor Belt (also called Gravimetric Feeder Belts). We have a long list of satisfied clients who are using our Coal Feeder Conveyor Belt. Our Coal Feeder Conveyor Belt is a popular choice in power stations and cogeneration plants etc. The best feature of our Coal Feeder Conveyor Belt is its Flanges and V·guide which are integrally moulded on the rubber covers for giving the base belt maximum strength. In addition to this, the v-guide tracking strip fits in to the groove of the pulley, hence reducing tracking problems. Special Features Of Our Coal Feeder Conveyor Belt V guide strip reduces tracking problems These belts are designed to keep belts running consistently in proper alignment Flanged pattern prevents coal powder or lamps from spilling over edges during transportation Rubber covering give the base belt maximum strength Demanded By Power stations Cogeneration plants

Modular Belt Conveyor

Get Price Quote

1 Piece (MOQ)

Optimize your material handling processes with our high-quality conveyor belt systems designed to enhance efficiency, productivity, and safety in diverse industrial applications. Whether you're transporting bulk materials, packages, or finished products, our conveyor belts offer reliable and seamless conveying solutions tailored to meet your specific requirements. From heavy-duty mining operations to precision manufacturing facilities, our versatile conveyor systems provide unmatched performance and durability.Key Features : Robust Construction for Longevity : Our conveyor belts are constructed from premium materials such as reinforced rubber, PVC, or steel, ensuring durability and longevity even in harsh operating environments. Designed to withstand heavy loads, abrasion, and impact, our belts offer reliable performance and minimal downtime, maximizing uptime and operational efficiency. Versatile Configurations for Diverse Applications : With a range of configurations and customization options available, our conveyor belt systems are adaptable to various material handling tasks and industry-specific requirements. Whether you need straight conveyors, curved conveyors, inclined conveyors, or specialized conveying solutions, we offer versatile designs to suit your application. Smooth and Efficient Material Transport : Our conveyor belts feature smooth surfaces and precision engineering to ensure seamless material transport with minimal friction, reducing wear and tear on conveyed goods and maximizing throughput. Equipped with high-quality rollers, bearings, and drive systems, our belts offer smooth and reliable operation, enhancing productivity and product quality. Adjustable Speed and Control Options : Tailor the speed and control of material flow to match your production requirements with our adjustable conveyor belt systems. Incorporating variable frequency drives (VFDs) or other speed control mechanisms, our belts enable precise control over conveying speeds, allowing for optimal throughput and energy efficiency. Easy Installation and Maintenance : Designed for hassle-free installation and maintenance, our conveyor belt systems feature modular components and user-friendly interfaces that facilitate quick setup, adjustment, and servicing. With accessible inspection points and straightforward maintenance procedures, our belts minimize downtime and maintenance costs, ensuring uninterrupted operation.

Best Deals from Conveyor Components

Tensioning Machine

Get Price Quote

1 Piece (MOQ)

modular conveyor belt

25,000 Per Meter

3 Meter (MOQ)

chain guide

Get Price Quote

500 pieces (MOQ)

Rough Top PVC Conveyor Belts

Get Price Quote

The company is bracketed among the preeminent Manufacturers and Suppliers of Rough Top PVC Conveyor Belts from Gujarat. Manufactured in adherence with set industrial norms, our Rough Top PVC Conveyor Belts have huge demand in the market. Our Conveyor Belts are used in the assembly lines in the areas of packaging, tyre, food processing and other industries. We are capable of delivering bulk orders of the Conveyor Belts.

Conveyor Sprockets

Get Price Quote

We offer an extensive range of Conveyor Sprockets, which is exemplarily designed to suit the requirements of the customers. These Conveyor Sprockets are highly appreciated for their qualitative features and have attracted the clients to place repeated orders for the same. Our Conveyor Sprockets are also environment friendly as generate less noiseduring operation. Highlights Economically pricedOutstanding design structureDurable

Aluminum Grooved Roller

129 - 130 Per pieces

200 pieces (MOQ)

oil resistant belt

Get Price Quote

We consistently design, manufacture, export and supply High Grade: Oil Resistant Conveyor Belts that are in great demand by most of our desirable clients for their Bulk Handling Materials like Animal Fats, Oily Soap Concentrations, Paraffin Waxes, Oils & Greases, Soya Bean Draff, Cattle Feeds, Poultry Fish Feeds , Suphla & Potash, Industrial Chemicals & Solvents, Dye Penetrates, Ferro Sulphur, Fluxes- Phenolic, Carbon Tetra Chloride, Silica Gel, Caustic Soda Flakes, Flurochemicals etc. The Covers of Oil Resistant Belts & Chemical Resistant Conveyor Belts are made from Nitrile Rubber + S B R + PVC Chemical Compounds which have Zero Percent Penetrations Or Damaging effects on the carrying side of these belts. Our ‘V - conBull flex’ & ‘Bull flex’ Branded Belts have found their places in many of these Manufacturing & Handling Plants. These Belts totally confirm to IS: 1891 (Part – III) 1999 Norms.

Twin Screw Side Feeder

Get Price Quote

Our wide range also includes win Screw Side Feeder for feeding minerals like glass, calcium, and other mineral with force from side to main line. The Feeder has high DO-DI Volume & efficiency output and is controlled through AC inverter. These co rotating / counter rotating twin-screw side feeders are specifically designed to handle the higher rates and to achieve the required objective of extrusion.

ebonite roller

Get Price Quote

Ebonite Roller They are vital and most important equipment of the process of every machine. Several things like even surface, appropriate material of covering according to the application, consistent hardness over the surface along with perfection workmanship play vital role in the performance of the Roller. Properties Ebonite Covering Designed For Good Covering Strength & Excellent Toughness. Good Resistance To Moderate Chemicals & Mild Acid. Good Heat Resistance.

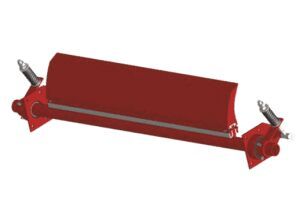

Secondary Belt Cleaner

9,500 - 9,600 Per PIECE

20 Piece (MOQ)

Material TC Brand Rabbit Country of Origin Made in India Thickness As per MI standard Structure Belt Scraper Color As per MI standard Usage/Application Bulk handling We are engaged in manufacturing and supplying high-quality Secondary Conveyor Belt Cleaner. The offered cleaner is finely manufactured using the best quality raw material as well cutting edge technology by our experienced professionals at our well-maintained production unit. This cleaner is highly acclaimed in the market due to its varied attributes like sturdy design and unmatched quality. Apart from this, our provided cleaner can be availed by our esteemed clients from us at rock bottom prices.Features: Flawless finish Easy to use Highly durable Product Description:Secondary Cleaner removes up to 97% of material clinging to the belt surfaces. They can be used singly or in tandem if necessary and, should be used in conjunction with a Primary scraper for optimum performance. X Multiple blade arrangement allows blades to conform to belt profile, especially when worn. X The angle of cleaning is always a Scraping angle which will not damage the Belt X Robust construction of cleaner assembly resists accidental damage. X, It also helps Blades to deflect to accommodate reversing belts. X The Blades deflect when encountering metal belt fasteners, belt repairs, or belt damage. X High-quality paint finish on all metal parts ensures optimum corrosion protection. View Complete Details Yes, I am interest

volumetric feeder

Get Price Quote

We are counted amongst the leading Volumetric Feeder Manufacturers, Exporters and Suppliers based in India. The Volumetric Feeders offered by us are ideal for feeding granules, chips and dove. In Volumetric Feeder, feeding is done with the help of auger and spiral screws. All the contact parts of Volumetric Feeder are made of non-corrosive steel SS304 grade and have separate agitator for conveying. Further, Volumetric Feeders are monitored through AC inverters.

pipe roller

Get Price Quote

We are acknowledged as a trustworthy name based in Vadodara(India) and offering products to diverse Vadodara(India)s. Every item in our range is manufactured utilizing premium supplies sourced from renowned traders. Therefore, our products are reliable.

Magnetic Grill

30,000 Per Piece

MAGNETIC BELT SEPARATOR

Get Price Quote

Packing Conveyor Belts

Get Price Quote

Conveyor belt are generally used to handle material from one point to another. It is also used for assembly line packing conveyor for pharmaceutical industries & other industries. Packing conveyor belts made by Legend Pharma Technologies of belts made of Nylon P.U.Silicon Teflon material and have higher tensile strength, longevity anVFD control. Belt-alignment system for long life & straight running of belt. Direct gear drive. Adjustable height of conveyor belt, to align with other machine of the line. d durability.

Idler Rollers

540 Per Piece

Impact Bar

Get Price Quote

Smartist Rubber Impact Bars are designed to absorb impact at the loading points of Conveyor Belts, where a combination of high energy absorption and low friction is needed. Due to ease of installation, these Impact Bars replace the conventional idler sets. The top cover is made of Ultra High Molecular Weight Polyethylene, which gives these Impact Bars a very low friction top surface. The middle portion is high-quality energy-absorbing rubber, which acts as a shock absorber at the loading zones of conveyor installation. These Impact Bars are also available with tapered ends on one side or on both sides to prevent any damage to the conveyor belt. Smartist Rubber Impact Bars come with a ‘T-Track’ fastening system, which enables variable fixing points throughout the length of the Bars. A ’T-Track’ fastening system also makes the element adaptable to any cradle arrangement, which the conveyor installation might have. The Impact Bars come in standard lengths of 1220mm, 1500mm and 1524mm with the top cover of UHMWPE and are supplied with 8 bolts and Nylock nuts as a standard accessory. Special sizes of Impact Bars are also manufactured on special requests.

Conveyor Roller

250 - 750 Per piece

Conveyor Primary scraper

10,000 Per Numbers

Conveyor Belt

Get Price Quote

Conveyor belts

Get Price Quote

We are glad to proclaim ourselves as the prime name amongst industrial conveyor belts manufacturers in india. We are the exclusive name that manufactures all the varieties of conveyor belts including rubber conveyor belts and others. Our rubber conveyor belts are stiff and perform up to their max on any given day. Our rubber conveyor belts are in multi models and shapes that make it adjustable as per ones’ requirement. Rubber conveyor belts manufactured by us have been tested and certified at international set standards. In addition, our rubber conveyor belts have been marked at the least market prices.

Screw Feeders

Get Price Quote

Our company offers screw feeders, which are used in various industries for the metering of material into a production process. These are engineered to perfection and are in high demand across various industries. Available in various dimensions, designs, sizes and working capacities these are high in performance, sturdy in construction and are appreciated for low power consumption.

Idler Rollers

Get Price Quote

The light weight Idler Rollers we offer is extensively used in the Packaging Industries, Pharmaceutical Industries, Paper Industries, Cement Industries, Conveyor Systems, Textile Industries, etc. The Idler Roller is manufactured using advanced processing technology. We also offer customized production facility of varied Slot Roller such as- Aluminum Roller, Crossover Aluminum Roller, Horizontal Center, Aluminum Roller, Roller and Cooling Roller. We offer the Idler Rollers at reasonable charges and in tamper proof packing. Manufactured With AluminiumMSSSSeamless Tube Sizes Available DIA-38 mm to 100 mm or depend upon drawing Attributes As much as half the weight of a comparable steel idler 40% - 60% lower rolling inertia than comparable steel idlersMore economical than other lightweight idlers Corrosion resistance higher than steelEasy to custom coat and surface treatMedium to heavy loading possibleRefurbishing of idler rolls possible due to thick-wall aluminum tubing Packaging Available Standard Packaging or as Customer’s Requirement Minimum Quantity Order 10 piece Price As per size, specifications & material used

Heat Resistant Conveyor Belt

Get Price Quote

We have unique concept and specialization to design, manufacture and cater ‘V - conBull flex’ - UHR -350° C U H R Conveyor Belts only for our desirable clients especially in Open Cast Cement Mining Sectors, Handling of Hot Clinkers, Conveying of Hot Crushed Cement Bags, Mfrs of Heavy Steel Structures Rolling & Re-Rolling Mills, Electrotherm Induction plants manufacturing M S Channels, Angels, Beams, Billets & Blooms, Carbon Steel, Galvanized Steel,

Idler Rollers

Get Price Quote

We are main supplier of this product.

Cold Resistant Conveyor Belts

Get Price Quote

disc type magnetic separator

Get Price Quote

Brief Introduction APPLICATION OF 3PC DISC DRY MAGNETIC SEPARATOR, BELT MAGNETIC SEPARATOR:EMI 3pc Disc Dry Magnetic Separator is a Dry Intensified Magnetic Separator, applicable for separations of ilmenite, rare earth ore, chromite, tungsten and tin ores, limonite, columbium and tantalum ores, ziron, rutile, monazite, andalusite, garnet, kyanite, feldspar, quartz and other minerals with magnetic differences or removal of iron in nonmetallic minerals. 4 varieties of products can be obtained by separation of the device. -STRUCTURE OF 3PC DISC DRY MAGNETIC SEPARATOR, BELT MAGNETIC SEPARATOR:—- Main device comprised feeding unit, weak magnetic roller, drive part, material conveying apparatus, magnetic disc, electromagnetic system, frame and others. The electric control section consists of components of control, voltage regulation, rectification, instrument and so on. It features compact structure, stable performance, easy installation and convenient operation and maintenance, this disc type dry belt magnetic separator has 3 types: 1 pc disc, 2 pcs disc, and 3 pcs disc. The following structure is showing the 2pcs disc dry magnetic separator. The moisture of the feeding material should be under 1%. —-ADVANTAGES OF 3PC DISK DRY MAGNETIC SEPARATOR, BELT MAGNETIC SEPARATOR:—- Very high magnetic field intensity 16000gauss – 20000gauss This separator can separate four different minerals in one time. This separator can get the final concentrate of three to four mineral. Ta &Nb grade can reach 60% by using this separator. It’s easy to install, adjust, and operate. The magnetic intensity of each disc is adjustable from 1000-20000 gauss, could be used for other mineral concentration.

steel conveyor belts

Get Price Quote

We have a complete devout in developing highly advantageous Honey Comb Steel Conveyor Belts. Specially demanded for food and acid resistant conveying applications, these belts are developed from 304 and 316 grade stainless steel material. We utilize cross rods and flat metal strips to fabricate the wire belt which is driven by sprockets. Further, our prestigious clients can order these high performing belts from us at a market leading price.INDOSWISS MODULAR BELTS NOW MADE IN INDIA.Features: 25 meter per minute conveying speed Rust proof finish Easy to install Long lasting performance