Turbine Flow Straightener

100,000 Per Piece

1 Piece (MOQ)

Turbine Flow Straightener Generally in pipelines pumps , piping bends, vibrations, control valves will generate swirl. Any swirl present in the fluid which enters into turbine meter can change the effective angle of engagement and hence deviation in the reading will take place and false reading will be take place. so it is required to install flow straightener before turbine meter to minimize liquid rotation , the swirl effect of the fluid After passing through the turbine meter the fluid enters into the downstream of the flow meter which is 5D flow straightener which controls any swirl existence on the rotor. It is good practice to keep minimum straight run of pipe 10 times diameter of pipeline at upstream of turbine meter and 5 times diameter of pipeline at downstream of turbine meter. Construction As this 10 D upstream flow straightener is 2 to 3 D upstream plenum then 2 to 3 D tube bundle with 7 or 19 nos stainless steel tubes with again 5D downstream plenum. 5D downstream flow straightener consists of simple piping. With optional port for pressure , temperature measurement. Turbine Flow Straightener

Material : Mild Steel

Color : White

Finishing : Powder Coated

Shape : Round

Usage : Industrial, Water And Chemicals

Country of Origin : India

Brand Name : Cryogenic Liquide

...more

strainer cum air eliminator

1 Bag (MOQ)

Cryogenic offers Basket type strainers for variety of installations and conditions and designed for straining and filtering of wide variety of fluids. As unfiltered liquid enters the strainer will directly passes through basket in which almost all impurities trapped into the basket and only clean liquid will pass through the outlet of strainer.Advanced dynamic flow and large filteration area elements ensure low pressure drops and reduce mainteneance period.Also it is designed such that it will not allow any bypassing of the liquid without filteration as basket is prevented by “ O “ Ring seal between basket flange and strainer internal flange. as well as retain position of basket even in case of reverse flow. Basket strainers are normally installed before the measuring devices like Positive displacement meter or turbine meter which increases accuracy of the measuring devices. We offer basket type strainers from 1” to 24” size with flow range upto 900 m3/hr or more & for pressure range upto 100 bar & design as per ASME Section VIII div I latest eddition.

Type : Strainer Cum Air Eliminator

Material : CS / SS 304 / SS 316 / HASTEALLOY

Application : Air Removal From Pipeline

Color : Depends On Specification

Pattern : Depends On Specification

Finishing : Paint Coated

Packaging Type : Corrugated Boxes

Country of Origin : India

Brand Name : Cryogenic Liquide

...more

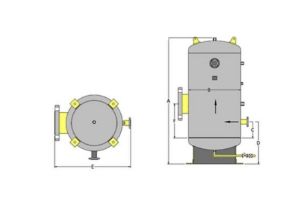

prover tank

1 Piece (MOQ)

Prover Tank Cryogenic offers Prover tank of capacity 50 ltrs to 5000 ltrs with different of material of construction and designed as per IS – 2341 code under the certification of weights and measures. We offer stationary as well as mobile prover tanks for use in checking commercial bulk measures, vehicle tanks, bulk meters etc. these are all made with same accuracy and quality as the smaller test measures. This provers are easy to use, reliable, and low cost way to measure the output accuracy of liquid metering equipment. For oil companies it is necessary to concern fairness and accuracy when liquids are sold, so after necessary time frame it is required to calibrate measuring devices.hence this prover tanks are portable in nature and prove the accuracy of measuring devices on site. We have credit of supplying a more than 200 units by 2014.

Country of Origin : India

Brand Name : Cryogenic Liquide

...more

Optical Air Eliminator

100,000 Per Piece

1 Piece (MOQ)

Optical Air Eliminator Cryogenic offers Optical Air Eliminators for mainly loading and unloading application . This optical air eliminator is mainly used where during low flow or flow with high air is present in flow condition.and when immediate flow needs to stop. Optical air eliminator works on principal of liquid level sense. This air eliminator is installed with optical sensor at different elevation in the air eliminator to sense the liquid level. When liquid level rises upto optical sensor level it instantly signal to the batch controller unit to start loading or unloading application. When loading/unloading application is about to complete there is chances on air with low flow with liquid which enters into the air eliminator and when liquid level go below optical sensor it signals batch controller unit to close the loading and unloading application. Benefits Faster response time. Two level optical sensor for double ensurity. Air Eliminators are bidirectional. it can be installed for flow direction Left to Right as well Right to Left. Vertical design which reduces installation space. High capacity air elimination provides good accuracy with safety of metering device. Simple interface with PD Meter ,Mass Flow Meter. If Used with Thermal Relief Valve protects all system components. Accurate Measurement. No complicated design for maintenance. Zero drain facility. Stainless Steel internals. Higher air eliminator retention time can be customized.

Type : Air Eliminators

Material : Mild Steel

Application : Industrial Use

Color : White

Pattern : Plain

Condition : New

Finishing : Paint Coated

Packaging Type : Corrugated Boxes

Country of Origin : India

Brand Name : Cryogenic Liquide

...more

master meter trolley

100,000 Per Piece

1 Piece (MOQ)

Cryogenic offers Air Eliminators for variety of installations and conditions and designed for separation, Elimination of air from the Liquid. without allowing the contained liquid to escape. Positive Displacement meter, is a volumetric measuring device can not differentiate between liquid, air and vapor. So when liquid enters with air or vapor into this measuring devices it will contribute the measurable error. Large amount of free air or vapor entrapped in the piping system, not only compromising meter accuracy but also lead to over speeding of meter and also creating excessive wear or unit failure. To ensure accurate liquid Measurement, it is necessary to remove all air from the system before entering into the measuring devices. Hence Air Eliminator is installed before the meter for accuracy of the measurement devices. We also offers Split type Air Eliminators for fuels like Aviation Turbine Fuel where frequent clearing is required. We offer Air Eliminators from 25 ltrs to 6000 ltrs with size of 1.5" to 24" with 150# to 600# with design as per ASME Section VIII div I.

Size : 2'' To 24''

Type : Master Meter Trolley

Material : CS/SS 304/ SS 316/ HASTEALLOY

Shape : Depends On Model

Color : Black

Brand Name : Cryogenic Liquide

...more

LPG Vapour Eliminator

100,000 Per Piece

1 Piece (MOQ)

LPG Vapour Eliminator We offer different size of gas/vapor separator for different products. it is mainly installed before Mass Flow Meter . Application of gas separator is to separate any vapor that arise in the flow will vent through top vent valve and which is collected in common vapor recovery tank. hence due to removal of vapor accuracy of the Mass Flow Meter increases and hence accurate product reading will be shown by Mass Flow meter. We have supplied this equipments for products Like LPG to various oil marketing companies like OIL INDIA LTD, ONGC, HPCL and OEM like EMERSON PROCESS MANAGEMENT. Benefits If Used with Thermal Relief Valve protects all system components. Accurate Measurement. No complicated design for maintenance. Zero drain facility. Stainless Steel internals. Higher retention time can be customized.

Material : Mild Steel

Color : White

Finishing : Powder Coating

Application : Industrial Use

Purity : 99.99%

Brand Name : Cryogenic Liquide

...more

lpg tanks

5,000 - 50,000 Per Piece

1 Piece (MOQ)

Size : On Customer Demand

Usage/Application : Storage Tank

Material Grade : Carbon Steel & Stainless Steel

Country of Origin : Made in India

Colour : On Customer Demand

Brand Name : Cryogenic Liquide

...more

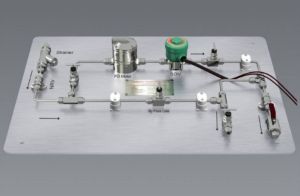

LPG Metering Skid

100,000 Per Piece

1 Piece (MOQ)

Gas, LPG Metering Skid Cryogenic manufacture complete skid for liquid and gas for measurement, control and filtration. this skids are fabricated with latest codes and international standard. metering system is manufactured for crude oil and hydrocarbon products such as LPG, Fuel Oil, Motor Spirit, Diesel, Kerosene. Cryogenic normally manufacture skids as per general arrangement drawings, P & ID provided by contractor who is overall system integrator. we design and detail piping, skid, platform static equipments as per clients datasheet. Major capital items like flow meter, Batch controller, PLC, instruments are free issued by clients or can be purchased and integrate by us with due consultation with client. We have wide range of approved WPS, PQR AND WPQ as per ASME SEC IX for different grade and class of materials and welding process of SMAW, GTAW, MIG. if required we can qualify WPQRs as per custom clients requirement as and when required. This Skids Are Mainly Consists Of Flow meter (PD Meter, Mass Flow Meter, Turbine Meter, Ultrasonic Flow Meter) Filters Air Eliminators Flow Straighteners. Digital Control Valves (Diaphragm or Piston Type) Valves and Piping. Instrumentation (Pressure and Temperature) Electrical (cabling and termination) Batch Controller Unit. Application Marketing and Distribution. Truck loading facility (TLF) Tank Wagon Loading (TWL) Transportation and distribution of hydrocarbon. Manufactured and Supplied more than 200 skids which is installed in domestic as well as globally.

Material : Stainless Steel

Color : White, Silver

Country of Origin : India

Capacity : As per Requirement

Installation Service : Yes

Brand Name : Cryogenic Liquide

...more

Liquid Metering System

100,000 Per Piece

1 Piece (MOQ)

Liquid Metering Skid (Truck Loading Metering/Tank Wagon Loading) Cryogenic manufacture complete skid for liquid and gas for measurement, control and filtration. this skids are fabricated with latest codes and international standard. metering system is manufactured for crude oil and hydrocarbon products such as LPG, Fuel Oil, Motor Spirit, Diesel, Kerosene. Cryogenic normally manufacture skids as per general arrangement drawings, P & ID provided by contractor who is overall system integrator. we design and detail piping, skid, platform static equipments as per clients datasheet. Major capital items like flow meter, Batch controller, PLC, instruments are free issued by clients or can be purchased and integrate by us with due consultation with client. We have wide range of approved WPS, PQR AND WPQ as per ASME SEC IX for different grade and class of materials and welding process of SMAW, GTAW, MIG. if required we can qualify WPQRs as per custom clients requirement as and when required. This Skids Are Mainly Consists Of Flow meter (PD Meter, Mass Flow Meter, Turbine Meter, Ultrasonic Flow Meter) Filters Air Eliminators Flow Straighteners. Digital Control Valves (Diaphragm or Piston Type) Valves and Piping. Instrumentation (Pressure and Temperature) Electrical (cabling and termination) Batch Controller Unit. Application Marketing and Distribution. Truck loading facility (TLF) Tank Wagon Loading (TWL) Transportation and distribution of hydrocarbon. Manufactured and Supplied more than 200 skids which is installed in domestic as well as globally.

Material : Mild Steel

Condition : New

Operating Type : Semi Automatic

Driven Type : Electric

Finishing : Polished

Usage : Industries

Country of Origin : India

Brand Name : Cryogenic Liquide

...more

Gas Metering and Blending Skid

100,000 Per Piece

1 Piece (MOQ)

Gas Metering and Blending Skid Cryogenic manufacture complete skid for measurement, control and filtration and blending of gas. These skids are fabricated with latest codes and international standard. Metering skid is manufactured for Natural Gas ,LPG ,CNG ,blending of products like propane , butane as demand of these product has increased significantly Cryogenic manufacture skids as per GAD , P&ID, PMS provided by contractor who is overall system integrator. We design and detail piping , skid, platform static equipments as per clients datasheet. Major capital items like mass flow meter , filter , vapor eliminator, static mixture, Control Valve, Analyser, Gas chromatograph, Pressure transmitter, Temperature transmitter ,free issued by clients or can be purchased and integrate by us with due consultation with client. We have wide range of approved WPS, PQR AND WPQ as per ASME SEC IX for different grade and class of materials and welding process of SMAW, GTAW, MIG if required we can qualify WPQRs as per custom clients requirement as and when required. This Skids Are Mainly Consists Of Flow meter ( Mass Flow Meter , Ultrasonic Flow Meter) Gas chromatograph Filters Vapour Eliminators Static Mixtures Flow Straighteners. Digital Control Valves (Diaphragm or Piston Type) Valves and Piping Instrumentation (Pressure and Temperature) Electrical (cabling and termination) Flow Computer Application Marketing and Distribution. Truck loading facility (TLF) Tank Wagon Loading (TWL) Transportation and distribution of Gas. Manufactured and Supplied more than 50 skids which is installed in domestic as well as globally.

Type : Gas Metering and Blending Skid

Application : Industrial

Color : Yellow

Condition : New

Surface Finishing : Coated

Country of Origin : India

...more

Condensate Pot

3,000 - 50,000 Per Piece

1 Piece (MOQ)

Size : On Customer Demand

Country of Origin : Made in India

Application : Structure Pipe

Material Grade : Carbon Steel & Stainless Steel

Brand Name : Cryogenic Liquide

...more

Blue Dye And Marker Injection Skid

100,000 Per Piece

1 Piece (MOQ)

Blue Dye And Marker Injection Skid Turbine meter generates pulses based on the Flow of product in the main pipeline header. These pulses are processed by the PLC for flow measurement of main product (SKO). Based On flow sensed in the main header, PLC will trigger a Start command for the Blue Dye pump (Motor) and also Open command for the solenoid (On – Off) Valves on the delivery header of Blue dye skid. Blue dye will then be injected into main product line as per a pre set ratio (say – 25 PPM) or by putting PD meter which will be connected to PLC. For every pre determined quantity of SKO (say 500 Litres) flowing through the header, the PLC Shall permit the solenoid (On - Off) valve on the blue dye delivery line to be open for a given Length of time in order to dose required quantity of blue dye. The flow rate of blue dye is always a constant parameter based on the settings of the positive displacement blue dye pump. Based on this flow rate, PLC shall monitor the time duration for which the solenoid (On – Off) valve shall Be in open condition. Once blue dye is dosed as per pre set ratio, PLC shall generate Close Signal For the solenoid (On – Off) valve. Quantity of blue dye pumped by the blue dosed is determined By the fixed flow rate of the positive displacement Blue Dye Pump. The dosing shall continue in cycles for every pre determined quantity (500 Litres) of the main product passing through the header. As the main product (SKO) flow rate increases, the blue dye dosing cycles will increase accordingly. Ratio and cycles can be changed manually through the PLC. Pressure in blue dye line is maintained by back pressure valve and sensed by pressure switch. Suitable HMI in the control unit shall be built to provide custom displays like Blue dye Motor Status, Solenoid (On – Off) Valve Status, Blue dye Agitator Status, Flow – rate of product in the main header, Quantity of blue dye dosed (based on no. Of times solenoid valve is energized) etc. Overview Of Blue Dye Dosing Panel Blue Dye Dosing panel ensure correct amount of Blue Dye dispensed at pre defined quantity set in PLC. The HMI provide display of On/Off status of Pump / Agitator, On/Off Status of Solenoid Valve, Flow rate of Main Product, and Quantity of blue dye dosed based on no of time solenoid valve is energized. The system operates under following two modes as per selection from Local HMI. HMI Provides Two Mode Of Operation Auto injection Manual injection This Mode Settable By User From Local HMI 1. Auto Mode Auto mode operates for Ratio Control Mode as per Selection. For Ration control, the flow of main product (SKO) through its Turbine flow meter (Pulse generator) is Fed as an input to the PLC system. Pulses are processed by the PLC for flow measurement of main product. Blue Dye dosing panel ensure that a correct amount of Blue Dye is dispensed with respect to Main product at all times on line in a predefined ratio ( set in the PLC) throughout the load cycle. When a pre defined quantity packet for main product passed then respective Blue dye SOV will be energized for a given length of time for a dosing of Blue Dye. On dosing of pre defined quantity for Blue Dye Product, SOV will be de energized by PLC. The flow rate of Blue dye shall be always a constant parameter based on setting of the positive displacement blue dye pump. Based on this flow rate, time duration shall be decided and fed to PLC as set point for solenoid ON time. The Cycle continues during receipt in frequently dosing of packets of qty. 2. Manual Mode Manual mode can be operated from Local HMI User can Start / Stop Pump / Agitator manually. User can on / off Solenoid Valve manually. Major Components Of BLue Dye / Marker Dosing Skid Tank with Level Indicator. Diaphragm Pump with FLP motor. (02 Nos.) Back Pressure Valve, Non Return Valve, Ball Valve, Needle Valve. Agitator with Motor. Pressure Switch. Solenoid Valve. Pulsation Dampener. PLC Required Electrical like Junction Box, Pump selector switch, Isolator. Turbine meter with Flow Straightener. Strainer Cum Air eliminator in SKO line. Base Skid. Pressure gauge with isolation valve. PD meter – Optional. (if metering base injection is required)

Purity : 99%

Color : Silver

Form : Liquid

Pattern : Plain

Surface Finishing : Polished

Speciality : Optimum Quality

Usage : Industrial Use

Brand Name : Cryogenic Liquide

...more

Basket Strainers

1 Piece (MOQ)

Principle Of Operation Air Eliminator consists of top nozzle housing with float assembly which is made up of float and guide rod. Now when product is entered into air eliminator which consists of air / vapor through inlet nozzle it enters into large open vessel area which decrease the velocity of the fluid and try to bring liquid to the stable state and as flow strike to the baffle plate which separates liquid and air / vapor which again travel to the top of the vessel and release through the float assembly. Now when air is released and further liquid level is rise up to float assembly will push this assembly up and close the orifice area. Now when more air is coming into the system or vapor is generated it will again travel to the top and accumulate in the top housing and at a certain stage when collected air /vapor forces liquid level down, buoyant force acting on the float reduces, this will reduce float buoyancy and float drops down which allows air / vapor to escape through the seat orifice. Now as fluid replaces air, Float buoyancy again increases and allowing float to rise and close to orifice seat. We also offers Split type Air Eliminators for fuels like Aviation Turbine Fuel. We offer Air Eliminators from 25 ltrs to 6000 ltrs with size of 1” to 24” with 150# to 600# with design as per ASME Section VIII div I. We have credit of supplying a more than 3000 units by 2018. Benefits Air Eliminators are bidirectional. It can be installed for flow direction Left to Right as well Right to Left. Vertical design which reduces installation space. High capacity air elimination provides good accuracy with safety of metering device Simple interface with PD Meter, Mass Flow Meter, Turbine Meter If Used with Thermal Relief Valve protects all system components. Accurate Measurement. No complicated design for maintenance. Zero drain facility. Stainless Steel internals. Higher air eliminator retention time can be customized.

Type : Basket Strainers

Material : Metal

Shape : Round

Application : Industrial

Color : White

Feature : Durable, High Quality

Surface Finishing : Power Coated

Country of Origin : India

Brand Name : Cryogenic Liquide

...more

Alcohol Loading and Unloading skid

100,000 Per Piece

1 Piece (MOQ)

Country of Origin : India

Brand Name : Cryogenic Liquide

Air Receiver

100,000 Per Piece

1 Piece (MOQ)

Air Receiver (Air Receiver / Volume Bottle / Pressure Vessel) Air Receiver are tanks used for the compressed air storage and recommended to be in all compressed air system. Using air receiver of unsound or questionable construction can be very dangerous. Therefore, the American Society of Mechanical Engineers (ASME) has developed a code regarding the construction of unfired pressure vessels, which has been incorporated into many federal, state and local laws. This particular code is ASME Code Section VIII Division 1. AWe have manufactured more than 40 Nos. till 2014. We have manufactured Air receiver of capacity 0.1 M3 to 5M3 as per ASME Code Section VIII Division 1. Air Receivers are equipped with Safety valve, Pressure Gauge, Pressure switch, Hand holes or Manholes and a base for vertical air receiver. Air Receiver serves Several Important Purpose Decrease wear and tear on the compression module, capacity system and motor by reducing excessive compressor cycling. Eliminate pulsation from the discharge line. Separate some of the moisture, oil and solid particles that might be present from the air as it comes from the compressor. Contribute to reduced energy costs by minimizing electrical demand charges associated with excessive starting of the compressor motor.

Type : Air Receivers

Shape : Round

Application : Air Storage

Condition : New

Driven Type : Electric

Country of Origin : India

Tank Orientation : Vertical

Brand Name : Cryogenic Liquide

...more

Air Header

4,000 - 7,000 Per Piece

1 Piece (MOQ)

Type : Air Headers

Material : Stainless Steel

Condition : New

Packaging Type : As Per Customize

Size : Inlet 2

Machine Type : Manual

Brand Name : Cryogenic Liquide

...more

air eliminators

1 Piece (MOQ)

Principle Of Operation Air Eliminator consists of top nozzle housing with float assembly which is made up of float and guide rod. Now when product is entered into air eliminator which consists of air / vapor through inlet nozzle it enters into large open vessel area which decrease the velocity of the fluid and try to bring liquid to the stable state and as flow strike to the baffle plate which separates liquid and air / vapor which again travel to the top of the vessel and release through the float assembly. Now when air is released and further liquid level is rise up to float assembly will push this assembly up and close the orifice area. Now when more air is coming into the system or vapor is generated it will again travel to the top and accumulate in the top housing and at a certain stage when collected air /vapor forces liquid level down, buoyant force acting on the float reduces, this will reduce float buoyancy and float drops down which allows air / vapor to escape through the seat orifice. Now as fluid replaces air, Float buoyancy again increases and allowing float to rise and close to orifice seat. We also offers Split type Air Eliminators for fuels like Aviation Turbine Fuel. We offer Air Eliminators from 25 ltrs to 6000 ltrs with size of 1” to 24” with 150# to 600# with design as per ASME Section VIII div I. We have credit of supplying a more than 3000 units by 2018. Benefits Air Eliminators are bidirectional. It can be installed for flow direction Left to Right as well Right to Left. Vertical design which reduces installation space. High capacity air elimination provides good accuracy with safety of metering device Simple interface with PD Meter, Mass Flow Meter, Turbine Meter If Used with Thermal Relief Valve protects all system components. Accurate Measurement. No complicated design for maintenance. Zero drain facility. Stainless Steel internals. Higher air eliminator retention time can be customized.

Type : Air Eliminators

Material : Mild Steel

Application : Industrial Use

Pattern : Plain

Condition : New

Finishing : Paint Coated

Packaging Type : Corrugated Boxes

Country of Origin : India

Brand Name : Cryogenic Liquide

...more

additive injection panel

100,000 Per Piece

1 Piece (MOQ)

Additive Injection Panel (Block) Cryogenic offers Additive injection panel is widely used for injecting additives into main product line (HSD, MS, SKO). This additive injection panel is installed mainly at distribution facilities. It is very accurate in nature with low pressure drop. It mainly consists of additive oval gear meter, solenoid valve, strainer, check valves, needle valves and completely mounted on stainless steel / Aluminum panel Areas of Application. A petroleum B oil C chemicals D fuels E ink F Dye Proof of our quality and excellent price is the fact that over 250 panels were delivered to our customers by 2018. The most important users of our additives injection panels are the corporates like Indian Oil Corporation Limited, Bharat Petroleum Corporation Limited, Hindustan Petroleum Corporation Limited.

Size : Standard

Type : Additive Injection Blocks

Color : Mulit Colour

Country of Origin : India

Packaging Type : Paper Box

Application : Industries

Brand Name : Cryogenic Liquide

...more

Additive Dosing Skid

100,000 Per Piece

1 Piece (MOQ)

Additive Dosing Skid (For MS & HSD)* Cryogenic offers Additive dosing system is a very flexible System for the continuous and fully automatic dosing of additives into the main product line. We offer different dosing skid depending on the number of Loading points for different process parameters. with this in line dosing system mixed products can be produced automatically and economically. It mainly consists of additive storage tank, metering pump with flameproof motor, strainer, pulsation dampener, pressure gauge, non return valve, ball valve, back pressure valve to maintain the dosing pressure , base skid etc. product loading pump can be supplied along with the additive dosing skid (manual or pneumatically operated). Alongwith this skid we also provide complete wiring with electrical control panel for operation and selection pump which can be integrated with batch controller unit or PLC. The additive system can also be used for fuel colouring like Blue dye and marker dosing system. We offer additive dosing skid for MS, HSD, SKO. Proof of our quality and excellent price is the fact that over 500 units were delivered to our customers by 2018. The most important users of our additive systems are corporates like Indian Oil Corporation Limited, Bharat Petroleum Corporation Limited, Hindustan Petroleum Corporation Limited.

Type : Additive Dosing Skid

Feature : Fine Finished, Good Quality, Good Strength

Condition : New

Automatic Grade : Semi-Automatic

Power Source : Electric

Country of Origin : India

Brand Name : Cryogenic Liquide

...more

pipe spool fabrication

10,000 - 100,000 Per Bag

We are manufacturers of Spool pieces of Sizes Varying from 1'' to 24'' in various materials like CS, SS304 and SS 316.

Type : Pipe Spool Fabrication

Material : Austenitic Steel, Carbon Steel, Mild Steel, Stainless Steel, Steel

Shape : Rectangular, Round, Square

Certification : ISO Certified

Length : 1-1000mm, 1000-2000mm, 2000-3000mm, 3000-4000mm, 4000-5000mm

Application : Industrial Use

Grade : ASTM

Color : Black, Brown, Grey, Silver, Any color as per requirement

Feature : Anti Junk, Corrosion Proof, Excellent Quality, Fine Finishing, High Strength, Perfect Shape, Pickled

Finishing : Polished

Dimension : 10-100mm, 100-200mm, 200-300mm, 300-400mm, 400-500mm, 500-600mm, 600-700mm, 700-800mm, 800-900mm, 900-1000mm

...moreOpening Hours