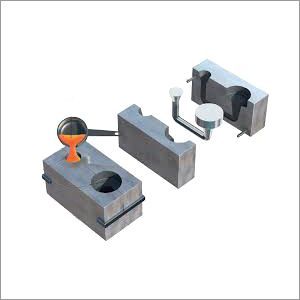

Gravity Die Castings

Get Price Quote

Keeping in mind the precise demands of clients, we manufacture and export a wide range of Gravity Die Castings. Gravity Die Castings are precisely engineered in accordance with world class standards and using advance technologies. Gravity Die Castings are acclaimed for robust construction, dimensional accuracy and consistent performance. Demands of Gravity Die Castings are increasing day by day owing to uninterrupted performance and purpose specific design.

Aluminium Gravity Die Casting Parts

260 Per Piece

2500 Piece(s) (MOQ)

Best Deals from Die Casting

Aluminium Extrusion Dies

12,000 - 24,000 Per Piece

1 Piece (MOQ)

Aluminium Extrusion World is a trusted Manufacturer and Supplier of high-quality Aluminium Extrusion Dies. Aluminium Extrusion Dies offer any shape to aluminium profile. We use the latest CAD/CAM software and 3D modeling for designing these Aluminium Extrusion Dies. Our designs are based on years of accumulated experience as well as feedback from our customers. We also manufacture various Extrusion Tools such as Die Rings, Bolsters, Sub –Bolsters and Insert Bolsters. Recently, we have started to manufacture press tooling.

Sand Casting

85 - 150 Per Kilogram

50 Piece(s) (MOQ)

Sand Casting

Get Price Quote

Pattern Wax, prototyping waxes, water soluble core waxes, repairing waxes

Pressure Vessels

Get Price Quote

We design Pressure Vessels per ASME Sec VIII Div-1 & 2, PD 5500, EN13445, AD 2000 and IS: 2589 codes. We and our associates can manufacture pressure vessels, columns, receivers, rotary reaction vessels, blending and dispersion vessels and storage tanks and all combinations of TEMA exchangers plus hair pin, pipe in pipe, tank coils, suction heaters, air fin coolers within code bounded practices. The cost effectiveness and timely delivery are our targets. We can execute jobs under Third-party inspection. We do supply all relevant documents along with the equipment and Operation & maintenance manual, preventive maintenance charts are facilitated for right operation and maintenance.

Pressure Vessels

Get Price Quote

Pressure vessel in Chemical Engineering A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. The term pressure vessel refers to vessels operating above the atmospheric pressure, or subject to external pressure.

Gravety Die Casting & Sand Casting Parts

Get Price Quote

We are engaged in offering a comprehensive range of ferrous & non ferrous gravity die casting & sand casting parts. Aluminium, cast iron, gunmetal, sg iron and any others metals. Ferrous & non ferrous gravity die casting & sand casting is widely used in locomotive application, as our range is leak proof & can even withstand high voltage application, manufacture and export an extensive range of industrial gravity die casting which archive to requirement of railways, automobiles and transmission line industries. these are fabricated from high grade raw material using advance machine to deliver defect free range. Thus, our range is renowned for their quality feature like durability, dimension, accuracy and corrosion resistance features. We offer our range in customized finishes as per the specifications provided by our clients. Our current product : transmission line part, automobiles parts, fasteners and any others industrial parts.

Pressure Vessels

Get Price Quote

We are engaged in providing an exclusive variety of Pressure Vessel to the patrons. These products are closed containers that are designed to hold gases or liquids at a pressure, which is substantially different from the ambient pressure. An engineering authority, which is backed up by laws is responsible to consequently regulate the design, manufacture and designs.

Zinc Die Casting

Get Price Quote

Pressure Vessels

Get Price Quote

Ascent undertakes design, detailed engineering, manufacture, testing, certification and code stamping of pressure vessels to ASME Sec VIII Div 1, Div 2 etc.. Pressure vessels for various applications such as air receivers, columns, reactors, towers, digesters, pig launchers - receivers etc. can be manufactured and / or repaired. Also, pressure vessels under Indian Boiler Regulations, 1950 such as boiler steam / mud drums, blow down tanks, HP Heaters, Deaerators, headers for various applications such as waterwall headers, economizer / superheater / reheater headers etc. can be manufactured and IBR stamped. We also manufacture pressurized transportable tanks for hazardous chemicals with Code Stamp. Ascent has a team of competent design engineers, design associates and draftsmen experienced in the field. Generally PV Elite supplemented with custom developed spread sheets is used for mechanical design and latest version of Autocad for drafting. Finite element analysis, stress analysis etc. can also be carried out by our design associates. In case process design or design of vessel internals is required, we can establish arrangements with well known European engineering companies operating from India or Europe. Materials of construction range from carbon steel, alloy steel through stainless steel including SMO (6% Mo) and Duplex / Super Duplex Stainless Steel and exotics such as Incolloy, Hastelloy, Monel, CuNi, Titanium etc. For material preparation, we have a oxy fuel torches. We can roll shells up to 25 mm thick and 2 M wide. Cold working is maximized with band saw, Universal Steel Worker etc. We have the entire range of welding gear viz., SAW and SMAW welding machines. We also have BugO Speed Weaver welding oscillator for GTAW / FCAW. There are also baking and holding ovens for welding electrodes and flux, apart from portable quivers for welders and welding operators. For stainless steel and exotics, there is a purpose built, segregated area. We have a well equipped machine shop with radial drill and 3 gap bed centrelathes.We also have a magnetic drill up to 50 mm diameter and 50mm thickness. We also have a Broach cutter. We carry out post weld heat treatment / stress relieving in temporary purpose built temporary furnaces within our facility or in gas fired furnaces at a specialist subcontractor’s premises. Semi automatic and manual FCAW is used for welding of saddles, supports and stiffeners. Hydro testing up to 600 bar can be done with or without chart recorders. Pneumatic testing and / or helium leak testing could also be done at our workshop by 3rd party. Country specific compliance certification such as that for Malaysia, Singapore, Australia etc. can also be arranged through authorized third party inspection agencies such as Bureau Veritas. This would facilitate seamless integration of our pressure vessels into the project in the country of installation. We have an extensive range of WPQRs to ASME Sec IX and EN ISO 15614 covering a wide range of materials, thicknesses, processes and other variables. All our WPQRs are witnessed and certified by third party inspection agencies such as Bureau Veritas, TUV Nord etc. Welders could also be qualified in presence of third party inspection agencies if it is a requirement. If Client requires us to appoint an independent third party inspection or certification agency, it could be arranged. If rubber / PTFE / PPE lining is required for pressure vessels, these could be arranged through specialist subcontractors. Non destructive testing such as radiography, ultrasound etc. and material testing at NABL accredited testing facility is available within reach. Management team has extensive experience in the heavy engineering industry within and outside India, especially with multi national companies, EPC global contractors, service providers etc. We have competent QC Inspectors, AWS/CSWIP 3.1/3.2 Certified Welding Inspectors, API 510 Pressure Vessel Inspectors and BGAS Grade II Painting Inspectors. In short, you are assured of a truly world class service within India. For a list of pressure vessel projects recently executed / in progress,

Die Stamping Metal Components

Get Price Quote

We have state of the art manufacturing facility that is equipped with all the latest machines and equipment used to manufacture precise range of high tonnage die stamping metal components of various shapes and sizes as per customers� requirement. We have expertise in mass production of customized, engineered and special purpose sheet metal based components. We are manufacturing world class Die Stamping Metal Components of Stainless Steel, brass and copper as well as mild steel. Advantages of MEW In-house customer tooling that is used to produce stamping components, is maintained by replacing worn-out or broken punches, die sharpening or anything that is required to produce components strictly as per customer drawings. Whether MEW is making your first production part or the millionth, quality is consistent. Some of the products that we have offered our customers in various shapes and sizes with different material as required for specific application

Pressure Vessels

Get Price Quote

Our product range includes air receivers, surge tanks, accumulators, blowdown tanks, flash tanks, expansion tanks, filter vessel, distillation columns, hot water generators, hydropneumatic tanks, nitrogen storage tanks, LP heater assembly, propane tanks, propane dispenser tanks, pressure vessels, refrigeration vessels, horizontal ammonia receivers, vertical ammonia receivers, oil pots, scrubbers, separators and more.

Cast Resin Components

Get Price Quote

Insulation Level Up to 36kV; BIL 170 kVp Outer Encapsulation Epoxy resin, Cycloaliphatic resin for outdoor use Mechanical Loads To customer requirements Electrical Characteristics Tested for HV, PD and Impulse with traceable serial numbers Custom Options (contact us) Contacts can be copper, Aluminum, Brass and MS (for Insulators and VDI) VDI available with Phase comparator or auxiliary contacts Shrouds, Spouts to customer drawing Special bushings for RMU application Range capabilities LV insulators MV insulators for panel applications MV insulators for outdoor applications LV Bushings MV bushings for panel applications MV bushings for outdoor applications MV wall through bushings Assemblies Capacitive dividers Indicators with or without relays for capacitive dividers Spouts and bus bar supports Secondary connection plate with through wires or inserts We can design and manufacture as per customer requirements.

Sand Casting

Get Price Quote

Aluminium Die Casting Part

Get Price Quote

aluminium extrusion die

20,000 Per Piece

1 Piece (MOQ)

Sand Casting

Get Price Quote

Pressure Vessels

Get Price Quote

We manufacture custom pressure vessels to suit the process requirements of the end user. We design the equipment after thoroughly understanding our customer’s requirements and their intended use to ensure high-quality output. By incorporating factors such as place and location of installation, service line piping, loaded applicable as well as the local statutory requirements, we are able to provide process guarantee. Each pressure vessel is fabricated using ASME standards. We also provide “U”, “U2” & “R” stamp and NB registrations. GENERAL FEATURES Statutory requirements are provided for pressure vessels, reactors, columns and heat exchangers falling under specific Indian process and lethal chemical processing equipment. All material procured from reputed suppliers with test certificates to ascertain perfection of material as per client specification & code requirements for quality assurance. Customization available for various segments of Chemical, Pharmaceuticals, Petrochemical, Refineries, Paper and Pulp & various other segments of process industries. Plate bending facility up to 50 mm. Types of welding processed used SAW, SMAW, TIG & MIG Non-Destructive and destructive testing methods used to check if our quality of our pressure vessels, reactors, columns and heat exchangers MATERIALS OF CONSTRUCTION Carbon Steel Hastalloy Nickel Cupronickel Titanium Duplex Super Duplex Boiler quality plates Low temperature Alloys Stainless Steel of Various Grades Pipes, Tubes, and Fasteners of Various Grades

Blanking Dies

Get Price Quote

Although Blanking Dies are the simplest type of dies, they are quite possibly, the most important. Almost all work that involves other types of dies as well as many manufacturing operations begin with the Blanking Dies, which explains why the blanking die is one of the most often ordered types of die. The Blanking Dies cuts around the contour of a part to produce plain, flat pieces of stock. Frequently, the work is completed in a single operation, at one stroke of the press. Even compression in the blanking process results in a flat part for use in additional manufacturing operations. We offer Blanking Dies in different specifications.

Pressure Vessels

Get Price Quote

JKE undertakes design, detailed engineering, manufacture, testing, certification and code stamping of pressure vessels to ASME Sec VIII Div 1, Div 2 etc.. Pressure vessels for various applications such as air receivers, columns, reactors, towers, digesters, pig launchers - receivers etc. can be manufactured and / or repaired. Also, pressure vessels under Indian Boiler Regulations, 1950 such as boiler steam / mud drums, blow down tanks, HP Heaters, Deaerators, headers for various applications such as waterwall headers, economizer / superheater / reheater headers etc. can be manufactured and IBR stamped.We also manufacture pressurized transportable tanks for hazardous chemicals with Code Stamp. JKE has a team of competent design engineers, design associates and draftsmen experienced in the field. Generally PV Elite supplemented with custom developed spread sheets is used for mechanical design and latest version of Autocad for drafting. Finite element analysis, stress analysis etc. can also be carried out by our design associates. In case process design or design of vessel internals is required, we can establish arrangements with well known European engineering companies operating from India or Europe.Materials of construction range from carbon steel, alloy steel through stainless steel including SMO (6% Mo) and Duplex / Super Duplex Stainless Steel and exotics such as Incolloy, Hastelloy, Monel, CuNi, Titanium etc. For material preparation, we have a oxy fuel torches. We can roll shells up to 25 mm thick and 2 M wide. Cold working is maximized with band saw, Universal Steel Worker etc.We have the entire range of welding gear viz., SAW and SMAW welding machines. We also have BugO Speed Weaver welding oscillator for GTAW / FCAW. There are also baking and holding ovens for welding electrodes and flux, apart from portable quivers for welders and welding operators. For stainless steel and exotics, there is a purpose built, segregated area.We have a well equipped machine shop with radial drill and 3 gap bed centrelathes.We also have a magnetic drill up to 50 mm diameter and 50mm thickness. We also have a Broach cutter.We carry out post weld heat treatment / stress relieving in temporary purpose built temporary furnaces within our facility or in gas fired furnaces at a specialist subcontractor’s premises. Semi automatic and manual FCAW is used for welding of saddles, supports and stiffeners.Hydro testing up to 600 bar can be done with or without chart recorders. Pneumatic testing and / or helium leak testing could also be done at our workshop by 3rd party.Country specific compliance certification such as that for Malaysia, Singapore, Australia etc. can also be arranged through authorized third party inspection agencies such as Bureau Veritas. This would facilitate seamless integration of our pressure vessels into the project in the country of installation.We have an extensive range of WPQRs to ASME Sec IX and EN ISO 15614 covering a wide range of materials, thicknesses, processes and other variables. All our WPQRs are witnessed and certified by third party inspection agencies such as Bureau Veritas, TUV Nord etc. Welders could also be qualified in presence of third party inspection agencies if it is a requirement. If Client requires us to appoint an independent third party inspection or certification agency, it could be arranged.If rubber / PTFE / PPE lining is required for pressure vessels, these could be arranged through specialist subcontractors. Non destructive testing such as radiography, ultrasound etc. and material testing at NABL accredited testing facility is available within reach.Management team has extensive experience in the heavy engineering industry within and outside India, especially with multi national companies, EPC global contractors, service providers etc. We have competent QC Inspectors, AWS/CSWIP 3.1/3.2 Certified Welding Inspectors, API 510 Pressure Vessel Inspectors and BGAS Grade II Painting Inspectors. In short, you are assured of a truly world class service within India. For a list of pressure vessel projects recently executed / in progress,

aluminium extrusion die

15,500 Per Piece

Bending Die

Get Price Quote

Pressure Vessels

Get Price Quote

We use materials such as Carbon Steel, Carbon Steel with Copper Lining, Stainless Steels & Duplex Steel for manufacturing Pressure Vessels. We make available both Pressurized and Vented variants in Vertical & Horizontal shapes.

aluminium extrusion die

52,000 Per Piece

Pressure Vessels

Get Price Quote

BEV undertakes design, detailed engineering, manufacture, testing, certification and code stamping of pressure vessels to ASME Sec VIII Div 1, Div 2, BS 5500, IS 2825, AD 2000-Merkblatt etc. BEV holds ASME ‘U’ and U2 Stamps for manufacture and National Board ‘R’ Stamp for repair and recertification. BEV is also authorized by the National Board to use ‘NB’ Stamp. The plant is approved by Hartford Steam Boiler UK Ltd. (Notified Body) for manufacture of pressure vessels under Pressure Equipment Directive PED 2014/68/EU of the European Union, Module H1 and H. Pressure vessels for various applications such as air receivers, columns, reactors, towers, digesters, pig launchers - receivers etc. can be manufactured and / or repaired. Also, pressure vessels under Indian Boiler Regulations, 1950 such as boiler steam / mud drums, blow down tanks, HP Heaters, Deaerators, headers for various applications such as waterwall headers, economizer / superheater / reheater headers etc. can be manufactured and IBR stamped. We also manufacture pressurized transportable tanks for hazardous chemicals with Code Stamp, PED certification and IMDG, ADR, RID, US DOT, UK DfT certification. BEV has a team of competent design engineers, design associates and draftsmen experienced in the field. Generally PV Elite supplemented with custom developed spread sheets is used for mechanical design and latest version of Autocad for drafting. Finite element analysis, stress analysis etc. can also be carried out by our design associates. In case process design or design of vessel internals is required, we can establish arrangements with well known European engineering companies operating from India or Europe. Materials of construction range from carbon steel, alloy steel through stainless steel including SMO (6% Mo) and Duplex / Super Duplex Stainless Steel and exotics such as Incolloy, Hastelloy, Monel, CuNi, Titanium etc. For material preparation, we have a CNC profile cutter with plasma and oxy fuel torches. We can roll shells up to 85 mm thick and 3.2 M wide. Cold working is maximized with CNC band saw, Universal Steel Worker etc. We have a wide range of welding manipulators such as column and boom 4 M x 7 M, heavy duty rotators up to 100 tons and positioners up to 3 tons. We have the entire range of welding gear viz., SAW, SMAW, GTAW and FCAW welding machines. We also have BugO Speed Weaver welding oscillator for GTAW / FCAW. There are also baking and holding ovens for welding electrodes and flux, apart from portable quivers for welders and welding operators. For stainless steel and exotics, there is a purpose built, segregated area. We have a well equipped machine shop with a with a 3 Axis CNC Vertical Machining Centre Hartford PRO 3210 imported from Taiwan with bed size 3150 mm x 2100 mm with 70 bar through coolant BT50, 6000 rpm spindle, 20 tools ATC, right angle milling head and Fanuc controller. The machine shop also has a radial drill and 3 gap bed centre lathes. We carry out post weld heat treatment / stress relieving in temporary purpose built temporary furnaces within our facility or in gas fired furnaces at a specialist subcontractor’s premises. Semi automatic and manual FCAW is used for welding of saddles, supports and stiffeners. Hydro testing up to 600 bar can be done with or without chart recorders. Pneumatic testing and / or helium leak testing could also be done. For ASME Code Stamped jobs, we have an Authorised Inspection Services Agreement with Hartford Steam Boiler Inspection and Insurance Company of Connecticut. Hartford Steam Boiler International GmbH is the Notified Body for PED certification jobs. We also have a second AIA services agreement with Lloyds Insurance Inc. For special certification requirements such as US DOT, ADR, RID, UK DfT, IMDG etc., we engage Lloyds Register Verification Ltd. as the certification body. CUTR certification of pressure vessels for Russia or Kazakhstan can also be arranged through duly accredited certification bodies. Country specific compliance certification such as that for Malaysia, Singapore, Australia etc. can also be arranged through authorized third party inspection agencies such as Bureau Veritas. This would facilitate seamless integration of our pressure vessels into the project in the country of installation. We have an extensive range of WPQRs to ASME Sec IX and EN ISO 15614 covering a wide range of materials, thicknesses, processes and other variables. All our WPQRs are witnessed and certified by third party inspection agencies such as Bureau Veritas, TUV Nord etc. Welders could also be qualified in presence of third party inspection agencies if it is a requirement. If Client requires us to appoint an independent third party inspection or certification agency, it could be arranged. We have a totally enclosed steel grit blasting facility complying with Euro III norms imported from Hodge Clemco, UK. Its size is 16M (L) x 8 M (W) x 5 M (H). Items bigger than this are blasted under custom built canopies using 200 litres blast pots and copper slag as abrasive medium. Painting facility is fully equipped with air less spray painting machine as well as cup guns. Special erosion resistant internal coatings can be applied using Belzona or Ceramkote products. If rubber / PTFE / PPE lining is required for pressure vessels, these could be arranged through specialist subcontractors. Non destructive testing such as radiography, ultrasound etc. and material testing at NABL accredited testing facility is available within reach.

epoxy cast components

Get Price Quote

Embossing Die

Get Price Quote

Being one of the trusted firms in the industry, we are highly engaged in providing a unique range of Embossing Die. Features: • Robustness • Flawless finish • Resistant to corrosion Embossing Die Manufacturer in Vadodara,Gujarat,India

aluminium extrusion die

14,000 - 26,000 Per Piece

3 Piece(s) (MOQ)

Pressure Vessels

Get Price Quote

We manufacture and provide superior quality pressure vessels that are used across various industries. We use latest technology to ensure our pressure vessels are at par with international standard and are durable. We manufacture and export a wide range of pressure vessels, air/gas receiver tanks and other purpose equipment for various industries. We also manufacture pressure vessels/equipment with required dimensions of customers. We do the hydro-test of the vessels and then dry it quickly with the pneumatic air to prevent rusting. Made from the finest raw materials such as carbon steel and stainless steel these vessels are featured with • International Standard • Corrosion resistant • Durable We also manufacture red-oxides coats and colors as per customer's specification. Proper care is taken while welding procedure to prevent any risk of leakage as it undergoes high pressure.