solvent recovery plant

Get Price Quote

1 Set (MOQ)

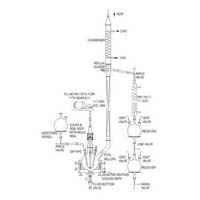

Recovery of solvents like : Acetone, Toluene, IPA, Ethanol, Methylene Chloride and many other norganic and organic solvents (VOCs)from liquid & gaseous effluents. Processes employed are Distillation (including azeotropic distillation), Extraction (Liquid-liquid & solid-liquid), Absorption, Adsorption, etc. We take up studies for the best possibilities of recovering solvents and other important chemicals from the liquid discharges as well as gaseous exhausts. Solvent recovery from liquid effluents can be from chemical & pharmaceutical manufacturing plants. Solvent & VOC recovery from Solvent Laden Air (SLA) can be from Rotogravure & coating machines used in polyester printing setups. Gasket, electrical part manufacturers, which use organic solvents in their processes. We offer turnkey projects for the above comprising of the following : TECHNOLOGY DEVEOPMENT : Piloting to scale up plant design & engineering BASIC ENGINEERING - Mass and energy balances , Piloting,Process flow diagram (PFD), Preliminary Plant layout , other apparatus and equipment specifications DETAIL ENGINEERING - P&ID , General arrangement drawing , E&I Specifications PROJECT MANAGEMENT - Scheduling, Resource management, Interface Management, Control INSTALLATION & COMMISSIONING – Construction management, Loop Check, Test run, Performance Test & Trouble-shooting. Solvent Recovery Plant from SLA Schematic Drawing

Standard Distillation System

Get Price Quote

10 pieces (MOQ)

Best Deals from Distillation Units

Automated Continuous Distillation Unit

Get Price Quote

Distillation is a separation technique used for separating two immiscible liquids based on the difference of their boiling points. Our Automated Continuous Distillation Unit allows the user to define and control the parameters of distillation process, carry out calculations on the data fed manually or automatically received from the process instruments and even save the data and results for evaluation or future use. Application: Our Automated Continuous Distillation Pilot plant finds its application at various levels: 1) Industrial R&D sectors – for separating two immiscible liquids having different boiling points, for concentrating chemical solutions by distilling off water from the solution, studying the process variables by defining and controlling other parameters. 2) Educational Laboratories – for understanding of students and carrying out experiments such as distillation with defined reflux ratio, distillation at defined operating pressure, pressure drop across column, calculation of relative volatility, calculation of column diameter, etc. We offer two types of Absorption column: Packed column (Different packing can be provided such as Raschig rings, Pall rings, Intalox saddles etc.) Sieve Tray column (Sampling points and thermometer pockets can be provided at different trays so that the tray hold-up can be collected for further evaluation, if required.)

Industrial Distillation Equipment

100,000 Per Piece

1 Piece (MOQ)

Fractional Distillation Unit

60,000 - 400,000 Per piece

1 Unit (MOQ)

Fractional Distillation Unit

100,000 - 1,000,000 Per

1 Box (MOQ)

Scientific glass Pilot plant for chemical & Pharma Industries. Fraction distillation unit.

Fractional Distillation Unit

200,000 - 2,500,000 Per Piece

1 Piece (MOQ)

Multi Column Distillation Plant

Get Price Quote

Legend Multi Column Distillation Unit consists of specially designed columns which make optimum use of the principles of inter-stage heat exchange to produce pure Pyrogen free sterile distilled water for Injectables as per IPBP specification. Advanced construction and ultra-modern design prevents any stagnation of water within the unit while Contamination Seal prevents cross-flow of air between the clean and un-clean area. Unit Capacity is available in 80 litres. , 150 litres. , 300 litres. , 500 litres. , 1000 litres range.

Reaction Distillation Unit

Get Price Quote

10 Set(s) (MOQ)

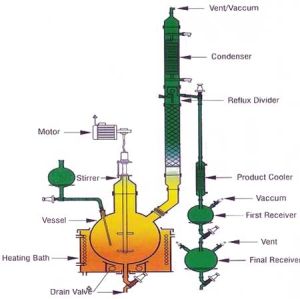

We offer reaction distillation unit. This unit is used for carrying out reactions under stirred condition and with provision for simple reflux distillation. the reaction vessel is mounted in a heating bath and fitted with addition vessel, motor-driven stirrer and provision for condensation with refluxing. the product is sub-cooled and collected in a receiver. The unit is available in vessel sizes of 20, 50, 100 & 200l, 300l and is suitable for operation under atmospheric pressure and full vacuum.

distillation units 10 lit

22,000 - 25,000 Per per unit

1 Set (MOQ)

Distillation Column

Get Price Quote

distillation column we are involved in providing our clients with distillation column project that includes complete solutions such as designing, commissioning and up gradation of resources used in installation. we ensure that these services are timely-executed and implemented under the careful guidance of our skilled engineers. these services are well-plotted based on the needs of the clients.

Reaction Distillation Unit

Get Price Quote

We are of the leading Manufacturers, Exporters and Suppliers of Reaction Distillation Unit in Vadodara, Gujarat. Our Distillation Unit is fabricated by experienced professionals who ensure smooth functioning and easy installation. We can provide Distillation Unit with different technical specifications n order to meet the varied requirements of buyers. Our Reaction Distillation Unit is available at the most desirable prices in the market. Description : The Unit has been designed to suit the customers requirement of combination of versatile reaction/distillation or combination for pilot plant work. This has a flexibility of working at atmospheric pressure as well as under vacuum. Typical unit has a reaction vessel fitted in a Metal Heating/Cooling bath having facility for heating and cooling both by means of Heating/Cooling Fluids as a media. The Standard system is equipped with stirrer having mechanical seal,a packed column on the side neck of the vessel, reflux divider, coil type condenser and or receiver system having a product, cooler, vent, drain and vacuum valves, Options of or speed variator by machanical variator or electronic variator can be provide. Receiver System is equipped with Product Cooler, Vent / Vacuum Valve and Drain Valve. The above units are available in 10 Ltr./20 Ltr./50 Ltr./100 Ltr./200 Ltr. Capacity with Spherical Reactor and up to 500 Ltr. capacity with Cylindrical Reactor.

Double Surface Distillation Condenser

950 Per Pack

6 Piece(s) (MOQ)

We are supplier of Double Surface Distillation Condenser.

Reaction Distillation Unit

Get Price Quote

We are engaged in manufacturing reaction distillation unit that designed using superior quality components. This reaction distillation unit is to be operated at atmospheric pressure or vaccum. Moreover, the reaction distillation unit is provided with agitator and liquid addition vessel this is the only that differentiate reaction distillation unit from fractional unit. the unit includesspherical vesseldrain valveheating baththermometer pocketliquid addition vesselagitatorpacked columncoil condenserproduct coolertwin receiversavailable in vessel size20, 50, 100 and 200 litres

Standard Typical Units

Get Price Quote

Simple Distillation Unit Reaction Distillation Unit Fractional Distillation Unit Reflux Reaction Cum Distillation Unit Multi-Purpose R&D Unit Mobile Vessel Jacketed Cylindrical Mixing Reactor Mixing Reactor Storage Tank of Volume 100-500 Liquid-Liquid Extraction Unit Solid Liquid Extraction Unit Typical Units/ Assemblies are multi-purpose units having flexibility of utility. These units have been standardised by incorporating all basic & essential features such as heating, stirring, condensation, fractionation, cooling etc. for multipurpose use. Therefore, though termed "Package Units" from constructional viewpoint they actually serve as "Flexi Units" from utility point of view.These units find use in educational institutions, R&D centers and industries. They can be conveniently and quickly modified according to specific process needs due to modular construction, Borosilicate glass offers additional benefits of universal corrosion resistance, visibility and cleanliness.

Fractional Distillation Unit

Get Price Quote

Distillation Column

Get Price Quote

Distillation is defined as a process in which a liquid or vapour mixture of two or more substances is separated into its component fractions of desired purity, by the application and removal of heat.

Brine Recovery System

Get Price Quote

We are a counted Brine Recovery System Manufacturer, Exporter and Supplier in India. We provide Brine Recovery Membrane Based Systems for sugar refineries and textile industries. The Brine Recovery System, we offer, delivers an excellent performance at a high pressure and a high salt concentration more than 5.8% concentrated brine. Further, to meet the specific requirements of the customers, we provide customized options for our Brine Recovery System.

Steam Distillation Unit

9,500 Per Piece

1 Piece (MOQ)

Water Distillation Unit

Get Price Quote

Technical Specification The still provides,4 liters/hr of distilled water produced through a power input of 3KW by a chromium plated heater housed in a horizontal glass boiler. Distilled output is cool insured by a high efficiency condenser. Temperature of distillate 25o C- 40o C tested for ambient room temperature of 30o C. All units carry marking. Distillate Quality Ideal for general laboratory use-capable of producing pyrogen free water.

Fractional Distillation Unit

Get Price Quote

Sieve Tray Distillation Column

Get Price Quote

Distillation Column

Get Price Quote

We are offering distillation column.

oil distillation plants equipments

Get Price Quote

oil distillation plants equipments, process plant equipments

Distillation Systems

Get Price Quote

GEA is your single-source supplier of complete systems, lines and plants for a variety of industries, from food to pharmaceutical, from brewing to biotechnology. Our experienced process engineers have the expertise and know-how to develop innovative and efficient process plants for your individual distillation and fermentation applications.

solvent distillation plant machinery

Get Price Quote

solvent distillation plant machinery, Fine Chemicals, Laboratory Chemicals

Ss Distillation Unit

Get Price Quote

Shivanand glass is dedicatedly engaged in the manufacturing and supplying of heavy duty ss distillation unit in the international market. The stainless steel distillation unit made available by us is accessible in teflon coated body. Our stainless steel distillations unit can be availed in the capacity of 5 ltr. To 200 ltr. They are extensively used in various laboratories for the sanitization of the liquid in different experimental applications. In addition to this, we are one of the most reputed laboratory distillation unit manufacturers and suppliers in india.

alcohol distillation plant

Get Price Quote

alcohol distillation plant, Industrial Distillation Column

distillation units

Get Price Quote

distillation units, Glass Pilot Plant, Hydro Extractor, Heat Exchangers

Distillation Column

Get Price Quote

Distillation Column, Agitator, Engineering Products, industrial reactors