Vibrating Grizzly Feeder

vibrating grizzly feeder manufacturers in India our Grizzly Feeder is able to withstand extreme shock loads. They are basically conveying deck with pan and grizzly combination, back and side renewable liners. Grizzly Feeder is non-plugging and stepped grizzly, separately renewable, for material tilting and easy fines passing. As leading Vibrating grizzly feeder manufacturers in India we have installed Vibrating unit consists of two contra-rotating eccentric shafts, geared together in oil-bath. Setting of amplitude is affected at still machine by varying unbalance. Actuation is by 4-pole motor and V-belts drive. Special steel springs are arranged for the installation on concrete or steel supporting structure.

...more

Vibrating Feeder

1,700,000 Per unit

1 unit (MOQ)

Voltage : 220 V

Capacity : 400TPH

Brand Name : Ecoman

...more

Vertical Shaft Impactors

Brand Name : Ecoman

Voltage : 380 V

Frequency : 50 Hz

...more

Vertical Shaft Impact Crusher

vertical shaft impact crusher manufacturers and exporters of eminent artificial and m-sand fabrication machines has been serving various industrial verticals. With extremely beneficial features of its impact crushers, Ecoman makes it pretty simple to cut down large rocks in to small size gravels. Believing in quality and efficiency, Ecoman has been producing high standard Vertical Shaft Impactor (VSI) machines that have received laurels from all the global clientele who used them in their specific industrial verticals.

Capacity : 40 to 280 TPH

...more

Versatile Vibrating Screens

Vibrating screens are specially crafted motorized devices that are used in applications across a spectrum of industries, be it the food, ceramics, sand and allied coarse or chemicals.One of India’s top-notch Vibrating screen manufacturers, Ecoman, particularly manufactures special type of vibrating screens which are powered by internal vibratory motor. The complete device is available in various sizes and types, specifically applicable for different types of industrial applications. The circular vibrating screen, which is the most commonly preferred screen of the two variants available in the market, is a robust screen specially crafted for coarse and medium fine applications.Circular vibrating screens are medium amplitude devices that come with an ordinary motor and based on the characteristics of the particle, amplitude and frequency of the device actually vary.Supported by springs, the circular vibrating screen comes with a shaft at the axis of the deck so as to keep the device working without any errors. Vibrating screens applications in varied industrial sectors Salt & Sugar Sand & Gravel Granular Materials Ceramics Pellets Crushed Stone Minerals

...more

Toothed Double Roll Crushers

Toothed Double Roll Crusher

The double roll crushers are strength wise great and best suitable for crushing any type of ores and rocks whose utility is more in chemical, mining and cement industries. Expanding into the fertilizer industry machine making, Ecoman makes distinguishing biomass and briquette crushing equipment and also the double roll crusher machines which have a greater demand in sectors where fertilizers are to be used.

...more

Stone Crusher

800,000 Per unit

Voltage : 440 V

Motor Type : AC Motor

Application : Stone Crushing

Production Capacity : 100 TPH

Brand Name : Ecoman

Automatic Grade : Automatic

...more

Slow Speed Impactor

You are here : Home > What we Manefacture > Slow Speed Impactors (Coal Impactors) Slow Speed Impactor (Coal Impactor) Manufacturers Being reputed slow speed Impactor, washery reject crusher, and coal Impactor manufacturers, our Impactors are suitable for crushing brittle and soft minerals like gypsum, limestone, slag, coal etc. We offer Coal Impactor included under slow speed Impactors and their core parts include rotor assembly with blow bars, bearings and flywheel, lower body, upper body with feeding chute and upper body rear side. What are the Features? Maximum throughputs Reduction ratio greater than 10 Operational reliability And easy maintenance Our slow speed Impactors are supremely engineered to give précised performance and optimum functionality. The slow speed Impactor consists of a fabricated enclosure that features adjustable 2 to 3 breaker plates and these plates remain in a suspended position. A massive rotor with 2 to 6 blow bars rotates with velocity of 25M/sec to 35m/sec. Now material is fed inside rotor and impacted back for further crushing. We are leading slow speed Impactor, washery reject crusher, and coal Impactor manufacturers, using ultra grade raw materials for designing our products. Our Impactors are able to withstand heavy loads and pressure. Our Impactors are available in different diameters based on clients’ specifications. We use systematic agile approach to manufacture right kind of machine. We also promise technical support and after sales services for our clients. In case of any issues, we are always ready to assist our customers.

...more

single toggle jaw crushers

We are the main supplier of this product.

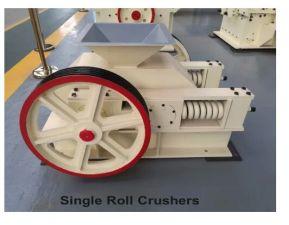

Single Roll Crushers

1,300,000 Per Piece

1 Piece (MOQ)

Brand Name : Ecoman

Automatic Grade : Automatic

Material : Steel

...more

Single Roll Crusher

You are here : Home > What we Manefacture > Single Roll Crushers Adding Perfection To The Industrial Processes With Single Roll Crusher Ecoman is one of the top most-preferred crusher manufacturing, selling and distribution company, which makes efficient and exclusively customized single roll crushers that best suit the special requirements of varied industrial applications.Alongside the double roll crusher machines that Ecoman manufactures, the single roll crusher machines also add a great value towards enhancing the scope for better production in various industries like \metallurgy, mining, building material and energy. We manufacture and distribute best quality single roll crusher as well as an eminent double roll crushers of two types - double toothed roll crushers and smooth double roll crushers along with sinter crushers.The single toothed roll crusher that we manufacture is actually a rotary roller which consists of a large tooth and also a crushing plate which is adjustable according to the need and requirement.The material that is fed into the single roll crusher is smashed first and then pressed from inside of the single tooth roll breaker followed by passing it through the braking cavity after which the rotary roller shifts it to the space amidst the tooth roller and the crushing plate which break the material into desired shapes. Our single roll crusher has a utility space in industries like ROM coal Mine refuse Shale Slate Gypsum Bauxite Salt Soft shale Cinders Brick Phosphate Clean coal Frozen coal Lime Coke Wet and Sticky feeds Salient features of our single roll crusher Fabricated steel base constructed frame Renewable, high quality steel wear liners based Hopper and frame reinforcement Replaceable, reversible and renewable crushing plates reinforcement Driven by an electric motor and V-belt drive arrangement Automatic lubrication option available

...more

Oil lubricated Double toggle jaw crusher

Being reputed Oil lubricated Double toggle and Grease lubricated Single toggle jaw crusher manufacturers, our single and double toggle jaw crushers are constructed of heavy duty fabricated plate frames with reinforcing ribs throughout. The crushers’ components are of high strength design to accept high power draw. Manganese steel is used for both fixed and movable jaw faces. Heavy flywheels allow crushing peaks on tough materials. Jaw Crusher is widely used as primary and secondary crushing equipment to crush material with compression strength less than 320 MPa. “It is widely used in Mining, Metallurgical, and Infrastructure/Construction Industries”

...more

Sand Making Unit

160,000 Per UNIT

Material : Mild Steel

Power : 10 kW

Voltage : 380 V

Brand Name : Ecoman

...more

riquette Crushing Machine

We are the leading Biomass and briquette crushing machine manufacturers selling and distributing wide range of crusher worldwide. Our crushers are widely accepted across various industrial sectors like metallurgy, mining, building material, energy etc. Our product range includes – single and double toothed roll crushers, smooth double roll crushers, and sinter crushers.

...more

Ring Granulator Coal, Stone and Fuel Crusher

We at Ecoman India are stone crusher manufacturers, coal crusher manufacturers, Fuel (coal) crusher manufacturers, and Ring Granulator coal crusher manufacturers selling best product range across Indian and overseas markets. Our supreme range of products has wide application in mining, construction, and allied industries. We are following strict quality guidelines while manufacturing our various types of crushers at our production house. Our crushers are remarkably suitable for grinding tough rocks, ore, lime stone, hard granite stones, river gravels, and coal etc. Some of main features of our different types of crushers include - Low power consumption, Maximum throughput, Optimum functionality, Low maintenance costs and Easy to operate To know more on to our product range and what makes us most reliable stone crusher manufacturers, coal crusher manufacturers, Fuel (coal) crusher manufacturers, and Ring Granulator coal crusher manufacturers, contact us right now.

...more

Ring granulator

Stone crusher manufacturers, coal crusher manufacturers, Fuel (coal) crusher manufacturers, and Ring Granulator coal crusher manufacturers selling best product range across Indian and overseas markets. Our supreme range of products has wide application in mining, construction, and allied industries. We are following strict quality guidelines while manufacturing our various types of crushers at our production house. Our crushers are remarkably suitable for grinding tough rocks, ore, lime stone, hard granite stones, river gravels, and coal etc.

...more

Reciprocating Feeders

Ore Crusher

165,000 Per unit

1 unit (MOQ)

Brand Name : Ecoman

Material : Iron

Color : Black

Voltage : 220 V

Frequency : 50 Hz

...more

Non Reversible Hammer Mill

150,000 Per Piece

Material : Mild Steel

Voltage : 280 V

Capacity : 1300 TPH

Frequency : 50 Hz

Phase : 3 Phase

Brand Name : Ecoman

...more

Lumps Breaker Machine

Breaking lumps into smaller pieces is not an easy job to do. You may have some myths that this can be done easily without putting any efforts but for précised action we must have to break lumps into required shape and size with proper dimensions at a fixed temperature of 450 degree Celsius. This task can be done precisely with our Lump breaker machines. Being reputed Industrial shredder manufacturers, our research and development team is putting maximum efforts in designing and manufacturing lump breaker machines for the purpose have been successfully operating at their optimum capacity & efficiency with Defense Establishments.

...more

lump breakers

Linear Motion Screen

Circular Motion Vibrating Screens have a limitation on Area of Deck to 14 to 18 square meters due to excessive load on the Bearings. Whereas Linear Motion Vibrating Screens can be a better solution as they can offer a larger area for screening. Screens up to 40 square meters of Deck Area can be available in Single or Double Deck construction.

...more

Jaw Crushers

Grease and Oil Lubricated Jaw Crushers Manufacturers Being reputed Oil lubricated Double toggle and Grease lubricated Single toggle jaw crusher manufacturers, our single and double toggle jaw crushers are constructed of heavy duty fabricated plate frames with reinforcing ribs throughout. The crushers’ components are of high strength design to accept high power draw. Manganese steel is used for both fixed and movable jaw faces. Heavy flywheels allow crushing peaks on tough materials. Jaw Crusher is widely used as primary and secondary crushing equipment to crush material with compression strength less than 320 MPa. “It is widely used in Mining, Metallurgical, and Infrastructure/Construction Industries” Grease Lubricated Single Toggle Jaw Crusher :

...moreBe first to Rate

Rate ThisOpening Hours