Falling Film Type Gas Absorber

Get Price Quote

Efficient gas absorption depends on the following: Intimate Contact Efficient Heat Transfer This is achieved in a Falling Film Absorber which is essentially a shell & tube heat exchanger in which both gas to be absorbed and absorbing liquid flow co-currently downward with the extraction of heat by circulation of coolant in the shell. The absorbing liquid is circulated through a tank till the desired concentration is achieved. The liquid flows at such a rate that the tubes do no flow full of the liquid but instead, descends by gravity along the inner walls of the tubes as a thin film. Obviously, this produces a much greater linear velocity for a given rate flow that could be obtained if the tube flowed full. The equipment works as a number of water cooled-wall columns in parallel and each tube is provided with distribution system on top to effect uniform distribution of both liquid and gas and also the formation of a thin liquid film on the inner surface of the tube. Other Area of Applications : Hydrogen Chloride Gas / Sulphur Dioxide Gas Absorption Hydrogen Chloride Gas / Chlorine Gas Absorption Hydrogen Bromide Gas absorption Hydrogen Chloride Gas / Chlorine Gas / Sulphur Dioxide Absorption Salient Features : High absorption efficiency High acid concentration is achievable Low outlet temperature Easy operation and maintenance Safe Operation due to a low isothermal temperature Handle a wide range of gas loading with minimum liquid flow rates to maintain full tube wetting Variation in Hydrogen Chloride Gas flow rates or Composition causes no operation problem. All the wetted parts of the falling film absorber are corrosion resistant to all the aggressive gases even at elevated temperatures

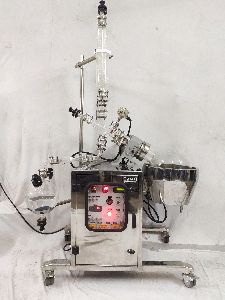

Rotary Film Evaporator-03

Get Price Quote

Our Rotary Film Evaporator is available with CE Marking as per PED - 97/23/EC, The Machine Directive - 98/37/EC, The European Low Voltage Directive - 73/23/EEC, The EMC Directive - 89/336/EEC. We have carved a niche as one of the overruling Rotary Evaporator Manufacturers based in India. In addition to this, we are also counted among the major Rotary Vaccum Film Evaporators Suppliers. The Rotary Film Evaporator is essentially a Thin Film Evaporator incorporating a rotating evaporation flask. The rotary evaporator will evaporate solvent at a much faster rate than systems using stationary evaporation flasks, due to higher convectional heat transfer coefficient. The rotation transfers a thin film of the liquid to the whole of the inner surface of the flask, markedly increasing evaporation rate due to higher heat transfer between the flask, bath and the thin film. The rotating flask and vapour duct have a sealing system, which allows operation under vacuum, further accelerating the evaporation process because of the reduction in boiling point of the solvent and efficient removal of the vapour. Besides the reduction in boiling point, there is a considerable decrease in the residence time of the fluid, which also permits heat sensitive materials to be successfully concentrated without degradation. The evaporators can be evacuated down to less than 1 mbar if the vacuum seals are maintained in good condition. A continuous feed facility considerably increases the capacity of the units and distillate withdrawal facilities on some units allow uninterrupted operation. Features Digital display & auto control of rotation speed, vapor temperature and bath temperature. Miniature circuit breaker and separate power switches for control panel and heating bath offers safety. Vacuum Controller (Optional) RS-232 / 485 interface (Optional) The units can be offered with full automation incorporating a PLC based system or even SCADA for real time data acquisition and control. There is a range of models covering an evaporation flask capacity from 1 litre 5 litres. The majority of these models may be used on the laboratory bench; the larger models (10, 20, 50, 100 litres and above) are designed for use in pilot plants and production facilities.

Best Deals from Evaporator

Rotary Film Evaporator

Get Price Quote

10 pieces (MOQ)

Manufactured after extensive research and hard work in the domain, our range of Rotary Film Evaporators is high on quality and performance. The range of Rotary Film Evaporators, offered by us, has features which make them demanded in pharmaceutical, chemical and biopharmaceutical industries. These Rotary Film Evaporators are stable, reliable and are known for its high performance sealing system.

Multi Effect Evaporator

100,000 Per Piece

1 Piece (MOQ)

Rotary Evaporator

Get Price Quote

We are a prominent Manufacturer, Exporter and Supplier of Rotary Evaporator in Gujarat, India. Our Evaporator is fabricated as per the international quality standards ensuring the best quality. The Evaporator that we offer has wide laboratory applications. We can provide Evaporator with varied technical specifications as per the requirements of different buyers. Our Rotary Evaporator is available at the best prices in the market. Description : The SUPER ROTA 50&100 rotary evaporator is simple to operate, with standard glass components and useful in a variety of laboratory applications. This could used at production facilities also. It is also available with control panel and electrical drives suitable for operation in explosion proof zones as optional. Available with simple control panel with clear vision and self-explanatory functions. LED displays for bath temperature, vapour temperature and RPM are standard features. Manometer for vacuum Measurement as part of supply. It can be offered with different condenser configurations like downward condenser, double condensers, short condenser etc. Motorized bath lift is standard supply. Speed control from 5 to 60 RPM with AC drive. Flask drive interlocked with bath lift Flask support supplied for easy fixing and removal of rotating flask Trolley mounted system permits easy movement from anywhere

Rotary Evaporator

Get Price Quote

5 Set(s) (MOQ)

We are offering rotary evaporator. The rotary evaporator principle is the most universal method, as it is an efficient, fast and gentle way to separate liquids. The rotating flask continuously covers a large surface area with a thin film, which is ideal for rapid heat transfer. Fortuitously, the film also ensures uniform heat distribution without local heating. the facility to work the unit under full vacuum further facilities evaporation at as low temperature as possible. These features, combined, renders rotary film evaporator to be ideally suited for evaporation of heat sensitive material. It is equally successful for evaporation of suspension in crystallization processes drying of powder / granule etc. salient features: table top model, sleek, compact with minimum footprint. very specific feature additionally incorporate & found useful in r&d areas such as continuous feed tube. High effective vertical condenser for maximizing recovery rates, provision for reflux distillation through reflux valve as an additional feature, total recovery of product condensate to recovery flask. designed especially for solvent separation-miscible & immiscible, crystallization. control panel located on the front of the unit thereby protecting the user from the hot water bath. heating bath features non-slip handles for safe up down movements of bath. At the time of power failure can also be operated manually. construction of vacuum seal is made of ptfe, which extends its life and reduce down time. indigenously developed vacuum seal mechanism in ptfe giving competitive edge against well-established rotary flask of international or other indian make. ip-55 insulation protection against dust & fumes.

Multi Effect Evaporator

Get Price Quote

A Multi Effect Evaporator, as defined in chemical engineering, is an apparatus for efficiently using the heat from steam to evaporate water. In a multiple-effect evaporator, water is boiled in a sequence of vessels, each held at a lower pressure than the last. Because the boiling temperature of water decreases as pressure decreases, the vapor boiled off in one vessel can be used to heat the next, and only the first vessel (at the highest pressure) requires an external source of heat. While in theory, evaporators may be built with an arbitrarily large number of stages, evaporators with more than four stages are rarely practical except in systems where the liquor is the desired product such as in chemical recovery systems where up to seven effects are used.

falling film absorber

Get Price Quote

This is achieved in a Falling Film Absorber which is essentially a shell & tube heat exchanger in which both gas to be absorbed and absorbing liquid flow co-currently downward with extraction of heat by circulation of coolant in the shell. The abssorbing liquid is circulated through a tank till desired concentration is achieved. The liquid flows at such a rate that the tubes do not flow full of the liquid but instead, descends by gravity along the inner walls of the tubes as a thin film. Obviously, this produces a much greater linear velocity for a giver rate flow than could be obtained if the tube flowed full. The equipment works as a number of water cooled-wall columns in parallel and each tube is provided with distribution system on top to effect uniform distribution of both liquid and gas and also formation of a thin liquid film on the inner surface of the tube.

Falling Film Evaporator

250,000 - 1,500,000 Per

1 Set (MOQ)

Multiple Effect Evaporator

Get Price Quote

Mild Steel Rotary Evaporator

Get Price Quote

multiple effect evaporators

5,000,000 - 50,000,000 Per each

1 n (MOQ)

Multiple effect evaporator for effluent and RO reject. Zero discharge and ZLD plant.

Rotary Evaporator

150,000 - 900,000 Per Piece

1 Piece(s) (MOQ)

Industrial Rotary Evaporator

295,000 - 450,000 Per piece

1 Piece (MOQ)

Rotary Film Evaporator

Get Price Quote

We manufacture and export rotary film evaporator that is used with spherical evaporating flasks. Our range of rotary film evaporators is widely demanded in the international market owing to its qualitative features. We offer rotary film evaporator in various specifications.

Rotary Film Evaporator

Get Price Quote

The rotating flask continuously covers a large surface area with a thin film which is ideal for rapid heat transfer. Fortuitously, the thin film also ensures uniform heat distribution without local heating. The facility to work the unit under full vacuum further facilitates evaporation at as low temperature as possible. That is to say, both boiling point and residence time are significantly reduced. These features combined, renders rotary film evaporator to be ideally suited for evaporation of heat sensitive material. It is equally successful for evaporation of suspension in crystallization processes, drying of powder granules etc.

Rotary Vacccum Evaporator

Get Price Quote

Multiple Effect Evaporator

Get Price Quote

Evaporator differs from crystallizers in which evaporation is concerned with concentrating a solution rather than producing or building crystals. Evaporation is distinguished from drying giving always liquid residue. Paramount offer multiple effect evaporator as stand alone process unit and also for treatment of RO concentrates to achieve zero liquid discharge in Wastewater treatment plant.

Chemical Evaporators

Get Price Quote

Multi Stage Evaporator

Get Price Quote

A Multi-Stage Evaporator, as defined in chemical engineering, is an apparatus for efficiently using the heat from steam to evaporate water.[1] In a multiple-effect evaporator, water is boiled in a sequence of vessels, each held at a lower pressure than the last. Because the boiling temperature of water decreases as pressure decreases, the vapour boiled off in one vessel can be used to heat the next, and only the first vessel (at the highest pressure) requires an external source of heat. While in theory, evaporators may be built with an arbitrarily large number of stages, evaporators with more than four stages are rarely practical except in systems where the liquor is the desired product such as in chemical recovery systems where up to seven effects are used.

Large Scale Rotary Evaporator

Get Price Quote

Laboratory Rotary Evaporator

Get Price Quote

Nitrogen evaporator

300,000 Per Units

falling film absorber

Get Price Quote

This is achieved in a Falling Film Absorber which is essentially a shell & tube heat exchanger in which both, gas to be absorbed and absorbing liquid, flows co-currently downward with extraction of heat by circulation of coolant in the shell. The absorbing liquid is circulated through a tank till desired concentration is achieved. The liquid flows at such a rate that the tubes do not flow full of the liquid but instead, descends by gravity along the inner walls of the tubes as a thin film. Obviously, this produces a much greater linear velocity for a given rate flow than could be obtained if the tube flowed full. The equipment works as a number of water cooled-wall columns in parallel and each tube is provided with distribution system on top to effect uniform distribution of both liquid and gas and also formation of a thin liquid film on the inner surface of the tube.

Rotary Vacuum Evaporator System

Get Price Quote

We Offer Our Rotary Vacuum Evaporator System in Different Forms and Sizes. this Rotary Vacuum Evaporator System Comes from the Reputed Manufacturers and Hence Guaranteed for Efficient Long Term Usage. These Rotary Vacuum Evaporator Systems are Available At Market Leading Prices. features outstanding Corrosion Resistancetransparencycatalytic, Inertnessphysiological Inertness applications pharmaceuticalschemicalsinstitutionsschoolscollegesgovernments Sectorsn.g.os

chemical vaporizer

80,000 Per Piece

continuous evaporator

Get Price Quote

Rotary Film Evaporator

Get Price Quote

Rotary Vacuum Evaporator

Get Price Quote

Finned Evaporator

500 Per Piece