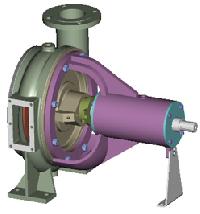

Horizontal Centrifugal Coupled Pumps

Get Price Quote

We are offering Cast-Iron Centrifugal Pumps. These are horizontal pumps: end suction, horizontal, centrifugal coupled pumps with semi open impeller. Our series JCP pumps are centrifugal semi open impeller type pumps smaller volume using less floor space Operating Range: Capacity : up to 40 m3 /hr Head : up to 48 hrs Size : 25 mm to 65 mm Temperature : 80oC Speed : up to 3500 rpm Pressure : up to 5 Kg/cm M.O.C : C.I, C.S., SS-304/304L SS 316/316 L, Bronze, Alloy-20, CD4MCU, Hast alloy B & C, etc Applications: Organic /inorganic chemicals volatile liquids, corrosive chemicals caustics process, effluent, filter press, slurry application Pharmaceutical, dyes, textiles, kerosene, diesel and other solvents ETP, STP & waste water treatment plant, fertilizers, cement and steel industries For pumping chemicals, with solids in suspension polluted liquids widely used for public and civil engineering Paper and pulp industries

Horizontal Non Clog Centrifugal Pump

Get Price Quote

Features Robust construction smooth operation Head hole cover facilitates cleaning Impeller with back vanes for reducing axial thrust Suitable for dry wet pit arrangement Shaft fitted with Replaceable Shaft sleeve Can handle solids up to 160 mm size

Best Deals from Horizontal Centrifugal Pumps

Horizontal Centrifugal Pump

9,990 Per Piece

Horizontal Centrifugal Pump

Get Price Quote

CHEMTROL FRP Pump series in India’s FIRST standard pump design non-metallic construction i.e. FRP developed to replace conventional alloy steel, lined and plastic construction pumps. The lower RPM advantage in our anticorrosive pumps are not there since maintenance is due to corrosion and not due to normal wear and tear. Hence the FRP pumps on 2900 RPM are most economical as compared to other on 1440 RPM. The wetted components of these pumps viz Casing, Casin Back Cover, Impeller, Impeller nut and Gland Pusher are of solid Moulded, Joint less, Composite structures of Fiberglass Reinforce Polyester Resin which ensure excellent resistance to corrosion and abrasion, superior impact resistance and mechanical strength.Amongst all non-metallic MOC, if we look at physical & mechanical properties, the resistance to corrosion, abrasion, temperature, mechanical strength, the superiority of FRP is proven. Moreover FRP components at times can be repaired unlike any other plastics. FRP is nothing but Fibreglass Reinforced Polyester Resin. Polyester resin being used are of Vinylester grade. Please note that polyester resin being thermo set type of plastic, these resin set permanently. This particular parameter facilitates strength as well as durability to FRP moulded components being incorporated in our FRP moulded pumps. We therefore strongly feel that FRP is the best corrosion resistant / reliable material amongst all plastics. Moreover due reinforcement of Fiberglass, the mechanical strength is better than any other non-metallic material of construction. For your perusal we are enclosing herewith “Physical & Mechanical Properties” of FRP. The type of casing incorporated in our FRP pump is volute type, which is in line with the standard available for horizontal end suction centrifugal chemical process pumps. This particular design will not be found in other non-metallic plastic pumps available in India. The construction features of our FRP pumps can be easily compared with various Indian, as well as International standard viz. IS 1520, DIN 24256 and API 610 etc. Since our FRP pumps have volute type of casings and there by efficiency is always better than any other casing in two halves of other non-metallic pumps supported with two metallic rings.With semi-open impeller to eliminate choking problems and with back-pull-out design to facilitate easy maintenance over and above standard gland packed pumps the mechanical seal arrangement include incorporation of one composite FRP mould consisting Impeller, Impeller Nut and Shaft sleeve i.e. Threaded Impeller with embedded sleeve. This particular feature renders absolutely leak-proof arrangement thereby preventing liquid penetration towards shaft. Hence this avoids incorporation stly alloy shafts. Moreover gland plate for holding mechanical seal is also offered in FRP construction. Easy external adjustment of impeller providing compensation for wear and ensuring consistent performance.Low weight to dimension ratio ensuring smooth and vibration free performance even in large sizes run at high speeds. Maximum parts interchangeability reducing spares inventory. Since only one model is quoted for all parameters with parallel installations. Heavy-duty bearings provide for smooth and cool operation even at higher speeds. The oil-sump in bearing housing is larger and stores more quantity of oil for efficient lubrication and cooling.

FRP Horizontal Centrifugal Pumps

Get Price Quote

FRP Horizontal Centrifugal Pumps, pump accessories