Glass Mixer Settler

Get Price Quote

The MIXER -SETTLER is a revolutionary new device, which makes phase separation automatic and simple, irrespective of the concentration of two phases (interface height). The mixer-settler is the name given to a type of EXTRACTOR made up of a number of mixing and settling chambers connected alternately in series. In the mixing chambers, optimum mass transfer is achieved by through mixing of two phases with the aid of pumps and stirrers. In the simplest case, the MIXER -SETTLER consist of an adjustable overflow valve, stirrer drive assembly and settling zone. The Mixer Settler has a wide application in the Process Industry , Particularly in Azeotropic Distillation Extractive Distillation Steam Distillation Esterification Distillation Stirrer Drive Assembly The mixing chamber consists of a cylindrical glass cover in which a variable speed stirrer drive is fitted. Glass impeller Stirrer creates a negative pressure at the inlet, which can be used to draw liquid from a previous stage in the process. In the mixing zone, a turbine stirrer with variable speed unit mixes the two phases and the mass transfer takes place during dispersion. Separation Zone Separation of phases takes place in two phases. Firstly, The turbulent flow in the mixing zone must be brought under control and converted into axial flow. Then the mixer passes into the separation zone where the two phases separate, due to their specific gravity difference. Auto Continuous Separation The adjustable overflow valve assembly at one end of the vessel can be set for any interface height. The position of the overflow weir is adjusted to suit the relative densities of the two phases. This valve can be operated externally such that the interface height can be set or reset depending on the operating process conditions. The separating head incorporates an internal overflow weir, which is manually adjusted using a hand wheel. Visual Monitoring The transparency of Borosilicate glass facilitates the adjustment of the overflow valve by visual monitoring whereby any change in the process conditions resulting into a change in layer (interface) height can be immediately adjusted by resetting the overflow valve. The resetting of the separation height is very simply achieved by rotating the hand wheel of the overflow valve assembly in the clock or anti-clock direction. Large Interface Plane Area The horizontal glass vessel of the MIXER-SETTLER provides a large interface area of separation two immiscible liquid phases for a given volume. This enhances the efficiency of the separation process. Overview Of The System The system consists of the following adjustable overflow valve, stirrer drive assembly and settling zone.

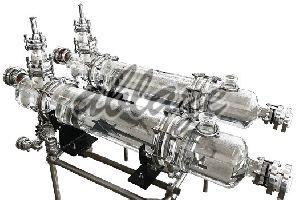

Mixer Settler

Get Price Quote

The MIXER -SETTLER is a revolutionary new device, which makes phase separation automatic and simple, irrespective of the concentr two phases (interface height). The mixer settler is the name given to a type of EXTRACTOR made up of a number of mixing and chambers connected alternately in series. In the mixing chambers optimum mass transfer is achieved by through mixing of two phases waid of pumps and stirrers. In the simplest case, the MIXER -SETTLER consist of adjustable overflow valve, stirrer drive assembly and zone.

Best Deals from Industrial Mixers

Industrial Stirrer

Get Price Quote

Stirrer material of construction: Glass, Stainless Steel or PTFE Lined.Stirrer Design: Impeller stirrer with blades, Vortex stirrer, Propeller Stirrer & anchor Stirrer.Stirring Drive: Non-flameproof or Flameproof stirrer drive, 192 RPM with Variable Frequency Drive.Stirring Assembly: Stirring Assembly with bellow seal or with mechanical seal.

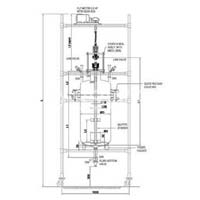

Mobile Mixing Vessels

Get Price Quote

We are an affluent Manufacturers, Exporters and Suppliers of Mobile Mixing Vessels in Gujarat, India. Our Mixing Vessels are easy to move from one place to another. We can provide Mixing Vessels that are quality tested and known for their durability. We can provide Mobile Mixing Vessels in variety of sizes and models so as to meet the different needs of buyers. Our Mixing Vessels are very reasonably priced. Description : Super offers trolley mounted mixing vessels from 5 liter to 500 liter. The vessels are supplied with graduations. The bottom drain valve can be simple straight through valve or flush bottom type for least hold up of liquid. Jacketed mixing vessels can be supplied up to 50-liter capacity. The agitator is of Mild steel lined with PTFE lining and PTFE blades. Pitch blade agitator is standard supply. The agitator is supplied as single stage or multistage depending upon the total length of the shaft and the agitation requirement. Technical Specification : Separator vessel - Borosilicate glass Drain valve for heavy phase - Borosilicate glass straight through OR Flush bottom valve Agitator - Mild steel PTFE lined pitch blade type Drive - 0.37 kw, 1440 rpm, flame proof induction motor, helical gear drive, Speed Control - Variable frequency drive Control Panel - Flame proof enclosure for VFD with ON-OFF push buttons Sealing - Single PTFE Bellow type dry running mechanical seal Supporting structure - Stainless Steel pipes and components with Supporting frame work - Supporting frame work is of 25 NB Stainless steel pipes and connectors. Mild steel powder coated trolley for movement

Glass Mixer Settler

Get Price Quote

Glass Mixer Settler, Glass Pilot Plant, rotary evaporators, Bioreactor

Industrial Stirrer

Get Price Quote

A variety of stirrer & stirrer drives are available to use glass vessels as agitated reaction equipment.

Jacketed Reactor

Get Price Quote

We are offering. jacketed reactor manufacturers and exporters in the country. Jacketed reactor vessel is a general purpose reactor, can be operated at atmospheric pressure, or vacuum. In addition, other type of stirrer can be also provided in place of anchor stirrer on demand. A battery 4ptfe baffles removable type is also provided with the same. Condenser assembly as per the requirement can be attached on the vapor nozzle.

Multi Stage Mixer Settlers

Get Price Quote

Multi Stage Mixer Settlers are used for liquid-liquid extraction process wherever there is huge demand towards flexibility in plant operations. Frequently changing products, alterations to the number of stages required or wide variation in through put can play decisive factors in this process.

Industrial Stirrer

Get Price Quote

Industrial Stirrer, Spherical Vessels, Line Valve, Laboratory Funnels

Mixing Tanks

Get Price Quote

Mixing Tanks, Horizontal Tanks, industrial vessel, air tanks

Paint Putty Mixer

Get Price Quote

Paint Putty Mixer, Car Polishing Pad, Hvlp Spray Gun, Electric Spray Gun