Mixer Settler

Get Price Quote

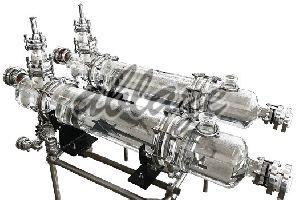

Mixer-Settler Extraction Unit The Mixer-settler system is fabricated and assembled in a compact modular design. The mixer as well as the settler are both integrated together instead of being separate entities. This allows the system to be compact and ideal for laboratory and R&D usage. A single stage of Mixer-Settler consists of a mixing zone and settler decanting zone connected to each other through a Weir zone. A brief description of the zones is as follows : Mixing System The Laboratory mixer consists of a special glass / SS (as per choice) mixing zone, suitable high-speed agitator and a variable speed drive. Besides providing an intimate dispersion the stirrer provides the necessary pumping action. This eliminates the need for external pumps and ensures a large interfacial area for mass transfer. The energy required to produce this dispersion will depend very much on the characteristics of the material and the system used (interfacial tension, viscosity, flow rates, etc). Between the mixing and separation zones, a weir is incorporated to prevent back mixing taking place and maintains the level of liquid in the mixing zone. Besides this, it also acts as a baffle to dampen the flow of liquid into the decanter (settler) for enhancing efficient phase separation. Settling System The settler comprises a horizontal cylindrical pipe which depending upon size may be one or more pipe sections. From the settler, the outlet of the heavy phase, is controlled by an overflow valve. The design of the settler will be influenced by the throughput of both phases and the material physical properties (density difference, viscosity, interfacial tension etc). Multi-Staging Mixer-Settlers Different stages can be connected to each other and the interconnecting pipelines can be done as per your required flow logic. The whole assembly would be controlled through a control panel consisting of suitable circuit breaker MCBs, Relays, digital controllers etc.

Ribbon Mixture Blender

150,000 - 2,000,000 Per Piece

1 Piece (MOQ)

Best Deals from Industrial Mixers

Ribbon Blender

Get Price Quote

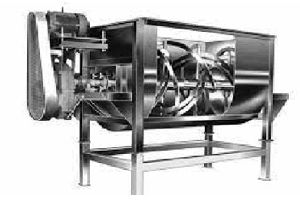

We are the prime manufacturer and supplier of Ribbon Blender, which is engineered with precision to give superior performance. The Ribbon blender mixes the homogenously. The high quality Ribbon blender is used in multiple industries such as chemical, pharmaceuticals etc. Characteristics : High efficiency Low maintenance cost Easy to use Easy to clean Low energy consumption Applications : Minerals Pesticides Chemicals Pigments Pharmaceuticals Dye stuffs

Glass Mixer Settler

Get Price Quote

The MIXER -SETTLER is a revolutionary new device, which makes phase separation automatic and simple, irrespective of the concentration of two phases (interface height). The mixer-settler is the name given to a type of EXTRACTOR made up of a number of mixing and settling chambers connected alternately in series. In the mixing chambers, optimum mass transfer is achieved by through mixing of two phases with the aid of pumps and stirrers. In the simplest case, the MIXER -SETTLER consist of an adjustable overflow valve, stirrer drive assembly and settling zone. The Mixer Settler has a wide application in the Process Industry , Particularly in Azeotropic Distillation Extractive Distillation Steam Distillation Esterification Distillation Stirrer Drive Assembly The mixing chamber consists of a cylindrical glass cover in which a variable speed stirrer drive is fitted. Glass impeller Stirrer creates a negative pressure at the inlet, which can be used to draw liquid from a previous stage in the process. In the mixing zone, a turbine stirrer with variable speed unit mixes the two phases and the mass transfer takes place during dispersion. Separation Zone Separation of phases takes place in two phases. Firstly, The turbulent flow in the mixing zone must be brought under control and converted into axial flow. Then the mixer passes into the separation zone where the two phases separate, due to their specific gravity difference. Auto Continuous Separation The adjustable overflow valve assembly at one end of the vessel can be set for any interface height. The position of the overflow weir is adjusted to suit the relative densities of the two phases. This valve can be operated externally such that the interface height can be set or reset depending on the operating process conditions. The separating head incorporates an internal overflow weir, which is manually adjusted using a hand wheel. Visual Monitoring The transparency of Borosilicate glass facilitates the adjustment of the overflow valve by visual monitoring whereby any change in the process conditions resulting into a change in layer (interface) height can be immediately adjusted by resetting the overflow valve. The resetting of the separation height is very simply achieved by rotating the hand wheel of the overflow valve assembly in the clock or anti-clock direction. Large Interface Plane Area The horizontal glass vessel of the MIXER-SETTLER provides a large interface area of separation two immiscible liquid phases for a given volume. This enhances the efficiency of the separation process. Overview Of The System The system consists of the following adjustable overflow valve, stirrer drive assembly and settling zone.

Static Mixer

5,000 Per piece

1 Piece (MOQ)

Static mixer

Glass Jacketed Mixing Unit

Get Price Quote

10 Set(s) (MOQ)

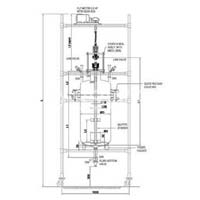

We are offering glass jacketed mixing unit. Mixing reactor systems represent a long-term evaluation of equipment and customer requirements. The mixing reactors are preferably used for wide applications in laboratory, pilot plant & for small-scale production. They reduce the need for investment in permanent installations & also reduce the pressure & temperature losses resulting from pipeline installations. these reactors are available with spherical shape & cylindrical shape. These reactors are also available in cylindrical jacketed form. construction of assembly : 1. Stirrer drive, non-flameproof or flameproof motor, 192 rpm. 2. Available with suitable condenser (hta m2) . 3. Stirrer shape glass impeller stirrer with ptfe blades, vortex stirrer, propeller stirrer & anchor stirrer. 4. Stirring assembly with bellow seal or with mechanical seal 5. Supporting structure in carbon steel, epoxy coated carbon steel, stainless steel 304 & stainless steel 316. All structures are available in trolley-mounted form. 6. Closing valves are available as a drain valve or flush bottom outlet valve.

Ribbon Blender

Get Price Quote

2 Piece (MOQ)

Post Bin Blender

Get Price Quote

Post Bin Blender can automatically finish the whole process of mixing. The equipment is constructed according to cGMP principles and is manufactured from AISI 316L grade. The equipment can be used for various size batches applying different sizes of bins. The Bin Blender comprises of post bin mounting arm hydraulic bin lifting mechanism, variable frequency drive arrangement, auto braking system for perfect positioning of bin after stop command and PLC control.

Skid Mounted Batch Mixer

Get Price Quote

chemical mixers

250,000 Per Pack

1 Set(s) (MOQ)

SS Mixing Vessel

Get Price Quote

Ribbon Blender

125,000 Per Piece

1 Piece(s) (MOQ)

High Speed Stirrer

42,000 - 50,000 Per piece

1 Number (MOQ)

High Speed Lab Stirrer machine for Paint and pHarma Industries

Intensive Mixer

170,000 Per Piece

1 Piece (MOQ)

FINEX RIBBON BLENDER

Get Price Quote

PESTICIDE FORMULATION PLANTS FOOD & PHARMACEUTICAL INDUSTRIESCHEMICAL PLANTS & MINERALS MANY OTHER APPLICATIONS.MIXING :Materials with widely varying densities can be mixed with high mixing efficiencies in a remarkably short time. Perfect distribution of even smallest quantities added is effected and final product homogeneity assured.SPECIAL FEATURES :In addition to mixing, shearing action in the interface provides mild kneading.Designed such that outer Ribbon convevers from end towards center. Whereas inner convevs from center toward end. Jacketed designs available for heating or cooling. Outboard bearings and stuffing box for eliminating product contamination.RUGGED CONSTRUCTION :Fabrication from heavy gauge MS or any other material of construction like SS304, SS316. Design for maximum mixing Efficiency in leak proof construction. Built for longer trouble free service.WIDE RANGE OF MODELS :Available in a range from a small 400 litres to 9900 litres Volumetric capacities to suit specific applications.Tailor made designers also available.

batch mixer

Get Price Quote

Ribbon Blender 7

Get Price Quote

we are offering the superior quality Ribbon Blenders from us. The Ribbon Blenders are constructed with stainless steel and mild steel. The blenders are provided with stuffing boxes that have been proven to be very effective for stopping leakage. It consists of a hopper and a discharge for loading and unloading of the processed material. The range of Ribbon Blenders offered by us is appreciated for their easy installation, smooth functionality and trouble free operation.

Industrial Stirrer

Get Price Quote

Stirrer material of construction: Glass, Stainless Steel or PTFE Lined.Stirrer Design: Impeller stirrer with blades, Vortex stirrer, Propeller Stirrer & anchor Stirrer.Stirring Drive: Non-flameproof or Flameproof stirrer drive, 192 RPM with Variable Frequency Drive.Stirring Assembly: Stirring Assembly with bellow seal or with mechanical seal.

Ribbon Blender

Get Price Quote

Leveraging on pour industrial experience, we are chiefly engaged in providing the best quality Ribbon Blenders in the world. The Ribbon Blenders that we proffer comprises of a U-shaped horizontal trough and a specially designed double helical ribbon agitator rotating within. These Ribbon Blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending. The dimensions and configuration of the ribbons in these Ribbon Blenders are carefully balanced to provide a movement of material within the container. Thus, this avoids dead spots and gives rapid product discharge. We offer, these industrial grade Ribbon Blenders at market leading prices. Specialty Of Our Ribbon Blenders Excellent designingReliable performanceSturdy constructionResistant to corrosion

Mass Mixer

Get Price Quote

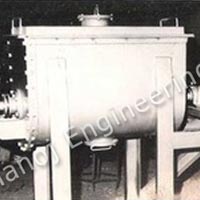

Mass mixer ideally used for mixing both wet & dry materials to provide uniform mixing. Designed with utmost precision & perfection our offered mass mixers are used for mixing & blending purposes.. The mass mixer is suitable for mixing of wet mass, dry powder, dry powder with wet mass, etc, for the preparation of pharmaceutical mass for preparing tablets and similar other applications. The mass mixer gives through mixing due to its unique blade design and the angle of the blade. Powder & Mass Mixer machines are designed for efficient and homogeneous mixing of dry and wet powders.

Mobile Mixing Vessels

91,000 - 251,000 Per Piece

1 Set (MOQ)

UD offers trolley mounted mixing vessels from 5 liter to 500 liter. The vessels are supplied with graduations. The bottom drain valve can be simple straight through valve or flush bottom type for least hold up of liquid. Jacketed mixing vessels can be supplied up to 50-liter capacity. The agitator is of Mild steel lined with PTFE lining and PTFE blades. Pitch blade agitator is standard supply. The agitator is supplied as single stage or multistage depending upon the total length of the shaft and the agitation requirement. Supporting framework Supporting framework is of 25 NB Stainless steel pipes and connectors Mild steel powder coated trolley for movement

Aeration and Mixing Equipment

Get Price Quote

In order to retain our goodwill in this industry, we are providing a qualitative array of Aeration and Mixing Equipment. Leading manufacturer of Aeration and Mixing Equipment in Vadodara, Gujarat, India.

batch mixer

Get Price Quote

Ribbon type mixer:- features:- suitable for dry mixing suitable for oil content < 4% homogeneous mixing mixing period – 3-5 min (depending upon ground particle size & feed formula) cv < = 7.5% return air chute furnished for internal & external pressure balancing pneumatically operated bom-bay type discharge flap spray nozzles for spraying molasses/oil/water etc. no death corner twin shaft paddle mixer:- features:- suitable for wet mixing suitable for oil content < 10% homogeneous mixing mixing period – 2-3 min (depending upon ground particle size & feed formula) cv < = 5% return air chute furnished for internal & external pressure balancing large cleaning door for easy maintenance pneumatically operated bom-bay type discharge flap spray nozzles for spraying molasses/oil/water etc. .

Granules Mixing Machine

75,000 Per Piece

Mobile Mixing Vessels

Get Price Quote

We are an affluent Manufacturers, Exporters and Suppliers of Mobile Mixing Vessels in Gujarat, India. Our Mixing Vessels are easy to move from one place to another. We can provide Mixing Vessels that are quality tested and known for their durability. We can provide Mobile Mixing Vessels in variety of sizes and models so as to meet the different needs of buyers. Our Mixing Vessels are very reasonably priced. Description : Super offers trolley mounted mixing vessels from 5 liter to 500 liter. The vessels are supplied with graduations. The bottom drain valve can be simple straight through valve or flush bottom type for least hold up of liquid. Jacketed mixing vessels can be supplied up to 50-liter capacity. The agitator is of Mild steel lined with PTFE lining and PTFE blades. Pitch blade agitator is standard supply. The agitator is supplied as single stage or multistage depending upon the total length of the shaft and the agitation requirement. Technical Specification : Separator vessel - Borosilicate glass Drain valve for heavy phase - Borosilicate glass straight through OR Flush bottom valve Agitator - Mild steel PTFE lined pitch blade type Drive - 0.37 kw, 1440 rpm, flame proof induction motor, helical gear drive, Speed Control - Variable frequency drive Control Panel - Flame proof enclosure for VFD with ON-OFF push buttons Sealing - Single PTFE Bellow type dry running mechanical seal Supporting structure - Stainless Steel pipes and components with Supporting frame work - Supporting frame work is of 25 NB Stainless steel pipes and connectors. Mild steel powder coated trolley for movement

Mixer Machine

125,000 - 500,000 Per kg

Ribbon Blender

Get Price Quote

The company has acquired the status of the leading Manufacturer and Supplier of Ribbon Blenders in Vadodara. The company is offering the best grade Ribbon Blenders to the clients that have diverse applications and are known for their efficiency. The Ribbon Blenders are available at the best prices and can be availed on a timely basis. Uses : Used for blending when material state is not in free flow Used for the purpose of bulk production of various chemicals Used in the preparation of pharmaceutical and agricultural materials in forms like powdered, solution or colloids

Jacketed Reactor

Get Price Quote

We are offering. jacketed reactor manufacturers and exporters in the country. Jacketed reactor vessel is a general purpose reactor, can be operated at atmospheric pressure, or vacuum. In addition, other type of stirrer can be also provided in place of anchor stirrer on demand. A battery 4ptfe baffles removable type is also provided with the same. Condenser assembly as per the requirement can be attached on the vapor nozzle.

V Blenders

Get Price Quote

Our rich industrial experience and domain expertise enables us to design and develop V Blenders having impeccable qualities. Developed with utmost precision, V Blenders delivers efficient performance. V-Blenders are widely appreciated for being efficient enough and having longer service life. The V-Blenders are available with us in different technical specifications as per the requirements. Highlights Longer service lifeResistance against corrosion Smooth finish Efficient performance

Industrial Stirrer

Get Price Quote

Suitable to mix syrups and liquids. The stirring shaft and propeller are made out of S.S. 316 quality and shaft is directly connected to motor. The motor can also be fitted on stand. Generally, the unit is mounted on a stand with base height adjustable up to 1'-0" up and down. All contact parts made out of S.S. 316 quality and stand cladded with S.S. 304 sheet. Stainless Steel parts are polished as matt finish.