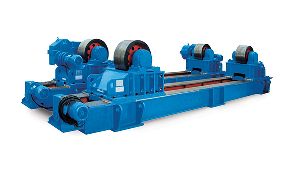

10MT Conventional Welding Rotator

310,000 - 350,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: Conventional Rotators Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle. Conventional Rotators: Built for Heavy-Duty Applications INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers. Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements. The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously. If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

Brand Name : Innovic

Driven Type : Electric

Condition : New

Application : Industrial

Feature : Easy To Operate, Long Life, Low Maintenance, Robust Construction

Voltage : 220-380V

Country of Origin : India

...more

Welding Positioner

100,000 - 350,000 Per Set

1 Set (MOQ)

Welding Positioners: Boosting Efficiency in Steel Fabrication Welding positioners are essential equipment for steel fabrication shops, enabling faster and more efficient handling of bulky fabrications. Designed to minimize the need for cranes and additional manpower, welding positioners allow fabrications to be easily placed in the optimal 'downhand' position. The positioner’s table rotates at precise, variable speeds and tilts through 135°, accommodating high center-of-gravity loads and enabling accurate welding of angular jobs. These welding positioners can also interface with Column and Boom Manipulators for seamless operation. Key Features of INNOVIC Welding Positioners: Durable Construction: Built with robust, all-steel fabrication for long-lasting performance. 360° Table Rotation: Variable or single-speed rotation options for complete control. Customizable Table Design: Available with square or round tables, featuring T-slots and concentric rings for fast, precise alignment and clamping. Tilt Functionality: Power-operated tilting mechanism through 135°, with limit switches to prevent overrun. High-Quality Bearings: Center spindle supported by sealed, pre-loaded bearings or large-diameter cross-roll bearings, depending on load capacity. Precision Gearing: Machine-cut steel gears for smooth, accurate operation. Efficient Earthing: Built-in earthing system for enhanced safety during operation. Enclosed Electrical System: Fully enclosed motors with electromagnetic brakes for added safety and reliability. Remote Control: Pendant remote push-button controls for all movements, including speed adjustment via a potentiometer. By investing in INNOVIC welding positioners, fabrication shops can significantly improve productivity, reduce labor costs, and ensure precise, consistent welds for a wide range of applications.

Driven Type : Electric

Condition : New

Automatic Grade : Automatic

Voltage : 110V to 480V

Country of Origin : India

Brand Name : Innovic

...more

Column and Boom Welding Manipulator

1 Piece (MOQ)

Column and Boom Manipulators: Precision and Stability for Welding Operations INNOVIC's Column and Boom Manipulators are engineered for precision, durability, and enhanced performance during welding operations. Designed to handle various welding processes, they provide stable and controlled movement of the welding head and boom, ensuring smooth operation even at extended heights and lengths. The manipulators are supported by precision cross-roll bearings, which eliminate free play, a crucial factor when the boom is fully raised and extended. Key Features of INNOVIC Column and Boom Manipulators: Precision Cross-Roll Bearings: These bearings ensure smooth and accurate rotation of the column, eliminating any free play that can lead to instability during operation. Larger machines come equipped with pre-loaded cross-roll bearings for added precision. Manual or Motorized Column Rotation: Column rotation can be motorized or manually locked in any of the 360° positions, allowing for flexibility in welding applications. Boom Elevation with Rack and Pinion Drive: Boom elevation is powered by a high-torque AC geared motor with an electromagnetic brake, providing smooth and reliable movement. Unlike chain or lead-screw mechanisms used by some competitors, INNOVIC uses a rack and pinion system to eliminate bounce and ensure consistent boom movement. Counterbalanced Design: The boom, welding head, and accessories are counterbalanced by a weight inside the column, reducing strain on the elevation gearing. This system enhances the stability of the machine, particularly when operating at full extension. Advanced Boom Traverse Drive: The boom traverse is driven by an AC frequency variable drive system, featuring a rack and pinion setup for smooth and controlled movement. A two-speed gearbox allows for slow retraction during cladding operations, accommodating processes such as spiral cladding using strip or wire electrode methods. High Load Capacity with Minimal Deflection: INNOVIC’s manipulators are designed to minimize deflection, even when carrying loads of up to 300 kg at the end of the boom. The combination of a precision cross-roll bearing and wide rollers ensures better stability and accuracy during operations. Customizable Configurations: INNOVIC Column and Boom Manipulators are available in five different designs, each tailored to meet the specific needs of various applications, such as cylindrical vessel manufacturing or high-precision welding tasks. Base and Travelling Carriage Options: Free-Standing Base or Travelling Carriage: The manipulators are designed with a robust base that provides maximum rigidity. The base can either be stationary or supported on wheels to form a travelling carriage, depending on the requirements. Travelling versions include either constant-speed or variable-speed drives for accurate tracking and movement. AC Motorized Column Rotation: Larger machines are equipped with motorized column rotation through an AC motor and heavy-duty reduction gearboxes, providing smooth start-stop movement and reducing strain on the system. Speeds and Performance: The manipulators offer precise control over speeds, ranging from as slow as 5 mm per minute to 1000 mm per minute, ensuring flexibility for various welding and cladding operations. These machines are ideal for applications requiring high stability and minimal deflection, such as spiral cladding or when handling heavy loads at extended boom lengths.

Condition : New

Automatic Grade : Automatic

Application : Industrial

Feature : Rugged Construction, Easy to Use

Voltage : 220-380V

Country of Origin : India

Brand Name : Innovic

...more

welding automation system

25,000 Per Piece

1 Piece (MOQ)

Welding SPM Automation: Customized Solutions for Superior Performance At INNOVIC, we specialize in providing advanced welding SPM (Special Purpose Machine) automation solutions tailored to meet the unique needs of our clients across various industries. With a commitment to innovation and quality, we take pride in designing and manufacturing customized welding automation systems that enhance productivity and efficiency in fabrication processes. Our Expertise in Welding Automation: Tailored Solutions: Customization is a key driving force behind INNOVIC's success. We recognize that every project presents unique challenges, and our team excels in creating bespoke welding automation solutions. From the initial design concept to final manufacturing, we ensure our systems align with the specific requirements of each client. Comprehensive Understanding: Our in-depth knowledge of welding processes and technologies enables us to provide world-class solutions. We collaborate closely with clients to assess their operational challenges and develop effective automation strategies that optimize performance and reduce cycle times. Professional Approach: At INNOVIC, we are dedicated to delivering ultimate welding solutions with a professional, customer-centric approach. Our team of experts ensures that clients receive high-quality, reliable, and efficient automation equipment that enhances their production capabilities. Innovation and Reliability: Our welding SPM automation systems incorporate the latest technology and engineering practices, ensuring they are both innovative and reliable. This commitment to quality has positioned us as a preferred supplier in the welding automation market. Industry Applications: Our solutions cater to a wide range of industries, including automotive, aerospace, construction, and heavy manufacturing. Whether it’s for spot welding, MIG/MAG welding, or specialized welding applications, we provide the equipment and support needed for success. Achieve Greater Efficiency with INNOVIC Welding SPM Automation: By choosing INNOVIC for your welding automation needs, you are investing in systems designed to enhance productivity, improve weld quality, and streamline manufacturing processes. Our dedication to customer satisfaction and technological advancement positions us as a leader in the welding automation sector.

...more

20MT Conventional Welding Rotator

360,000 - 390,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: Conventional Rotators Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle. Conventional Rotators: Built for Heavy-Duty Applications INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers. Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements. The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously. If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

Brand Name : Innovic

Driven Type : Electric

Color : Blue

Condition : New

Feature : Low Maintenance, Robust Construction

Voltage : 220-380V

Warranty : 1year

Country of Origin : India

...more

Self Aligning Rotator

These machines are built in capacities from 1 tonnes to 2000 tonnes. The frame is of robust fabricated construction and is machined on the top and underneath to ensure perfect alignment. Both the drive and the idler frames are provided with robust fabricated carriages which support the axles and bearings of the rubber polyurethane or steel rollers.

Brand Name : Innovic

...more

Rotary Turntable

50,000 - 100,000 Per Piece

1 Piece (MOQ)

Rotary Turntables: High-Precision Solutions for Workpiece Positioning Rotary turntables are essential tools for precise positioning of workpieces in the flat or horizontal position. They offer a cost-effective and efficient method for rotating components around a vertical axis, making them ideal for a variety of welding, assembly, and inspection applications. These turntables provide smooth, controlled movement, enhancing the accuracy and quality of operations. Key Features of INNOVIC Rotary Turntables: High-Precision Rotation: Designed for precise control, these turntables ensure accurate positioning of the workpiece, allowing for uniform welding, cutting, or assembly processes. Versatile Applications: Suitable for a wide range of industries, including fabrication, machining, and inspection tasks. Perfect for welding circular or symmetrical components where consistent rotation is required. Variable Speed Control: Equipped with adjustable speed settings, operators can tailor the rotation speed to suit specific job requirements, ensuring optimal performance for both high and low-speed operations. Heavy-Duty Construction: Built with a robust, all-steel fabrication, these rotary turntables are engineered to handle heavy loads while maintaining stability and accuracy during rotation. Compact and Ergonomic Design: The compact design allows easy integration into any workshop or production environment, while providing ergonomic benefits for the operator. 360° Rotation with Smooth Operation: Ensures smooth and continuous 360° rotation, ideal for welding, inspection, or machining tasks that require uninterrupted movement. Table Locking System: Integrated with a locking mechanism to secure the table in any position, offering added stability for detailed work or when repositioning is needed. Technical Advantages of INNOVIC Rotary Turntables: High Load Capacity: These rotary turntables can support heavy workpieces, ensuring versatility for applications ranging from light-duty tasks to handling large, bulky components. AC Motor with Variable Frequency Drive (VFD): The turntables are equipped with an AC motor and a VFD system for precise control of rotation speed, enhancing performance for both fast and slow operations, such as cladding, welding, or detailed assembly. Precision Bearings: The use of high-precision bearings ensures minimal friction and wear, providing long-lasting, reliable performance with minimal maintenance. T-Slot and Mounting Configurations: The turntable features T-slots and customizable mounting configurations for quick and secure attachment of various workpieces, making it adaptable for a wide range of applications. Integrated Safety Features: Designed with built-in safety mechanisms, including overload protection and emergency stop controls, ensuring safe operation even in demanding production environments. Enhanced Productivity for Welding and Fabrication: Rotary turntables are particularly advantageous for industries that require precise, repeatable positioning of workpieces, such as circular welding, plasma cutting, and inspection processes. Their ability to rotate components in a stable, controlled manner reduces operator fatigue and enhances production efficiency, leading to higher output quality and fewer errors.

Brand : Innovic

Driven Type : Electric

Shape : Round

Automation Grade : Semi-automatic

Application : Industrial

Country of Origin : India

...more

motorized material transfer wagon trolley

1 Piece (MOQ)

Motorized Material Transfer Wagons/Trolleys: Efficient and Reliable Material Handling Solutions Motorized material transfer wagons, also known as trolleys, are designed to transport heavy materials from one workshop bay to another. These trolleys operate on Indian standard rail sections, securely grouted into the ground, providing smooth and efficient movement. With load capacities ranging from 5 MT to 500 MT, these transfer wagons are custom-built to meet specific customer requirements. Key Features of INNOVIC Motorized Material Transfer Wagons/Trolleys: Robust Drive System: Each wagon is equipped with two drive wheels and two idler wheels. Power is delivered through both drive wheels using separate gearboxes and electric motors. The motors are synchronized using an AC Variable Frequency Drive, ensuring smooth and controlled movement. Depending on the load capacity, the number of drive and idler wheels can be adjusted for optimal performance. Radio Remote Control Operation: For ease of use, the wagons are fitted with a radio remote control system, allowing operators to move the trolley back and forth with precision and safety. Advanced Safety Features: To ensure safe operation, the trolleys are equipped with spring buffers or disc springs and two-way limit switches to prevent overrun. The control panel is also equipped with under-voltage and over-voltage protection for enhanced reliability. Warning Systems: Each transfer wagon is fitted with a siren and beacon lights to alert nearby personnel of its movement, enhancing workplace safety. Motorized Cable Reeling Drum: A motorized cable reeling drum ensures smooth cable feeding during operation, providing uninterrupted power supply to the trolley.

Brand Name : Innovic

Material : Steel

Finishing : Powder Coated

Color : Yellow & Black

Application : Factory, Warehouse

Feature : High Strength, Rust Proof

Country of Origin : India

...more

Load Positioners

Positioners provide steel fabrication shops with the most up-to-date equipment for placing bulky fabrications in the ‘downward’ position in the shortest possible time without the use of cranes and manpower. The positioners tables rotate at accurate and constant variable speeds and tilt through 135 DEGREE with a high CG load rating covering almost all angles for welding any angular job placed on it. Positioners can be supplied for interfacing with Column and Boom Manipulators.

Brand Name : Innovic

...more

Head Tail Stock Welding Positioner

1 Piece (MOQ)

Head Stock and Tail Stock Welding Positioners: Ideal for Long Workpieces Headstock and Tailstock positioners are essential for rotating long workpieces around a horizontal centerline, providing efficient handling and positioning. Typically, the headstock is powered while the tailstock remains free-wheeling, with no additional support required beneath the workpiece. These positioners are especially beneficial for turning large, complex structures, allowing welders to perform tasks more easily. In some cases, only a headstock unit is needed, as demonstrated in pipe spool fabrication. Head Stock and Tail Stock Welding Positioners INNOVIC’s headstock and tailstock welding positioners are versatile and well-suited for handling long objects. Typically used for rectangular shapes requiring support from both ends, these positioners provide ergonomic and efficient solutions for welding complex structures. Options include both fixed-height rotation centerlines and power-elevating models, offering flexibility for different job sizes and configurations. Key Features of INNOVIC Head Stock and Tail Stock Positioners: Capacity up to 100 Tons: Designed to handle heavy loads and large jobs with ease. Fixed and Variable Height Models: Choose from fixed-height or power-elevating models for ergonomic positioning. Customizable Center Height Adjustment: Center height adjustment available for larger job swings and improved flexibility in handling. Wide Rotation Speed Range: Supports all major welding processes, including MIG, TIG, and SAW welding. Advanced Control Options: Includes models with additional control capabilities for enhanced precision. In addition to the standard models, INNOVIC offers advanced versions with elevating headstock and tailstock configurations to cater to more complex welding requirements.

Brand Name : Innovic

Driven Type : Electric

Automatic Grade : Semi Automatic

Application : Industrial

Voltage : 220-380V

...more

75MT Self Aligning Welding Rotator

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: INNOVIC's self-aligning rotators automatically adjust to the diameter of the vessel as it is loaded. This eliminates the need for manual adjustments, making them ideal for handling a wide range of vessel sizes effortlessly. Self-Aligning Rotators: Precision and Efficiency INNOVIC’s self-aligning rotators are designed with trunnion brackets that automatically adjust the wheel alignment when transitioning between different diameters, eliminating the need for any manual adjustments. Each section of the rotator supports the vessel or job at four points, providing superior traction. On machines with capacities ranging from 3 tonnes to 500 tonnes and above, all four wheels on the drive section are positively driven. This four-point suspension offers a significant advantage, especially when handling thin-walled vessels, ensuring even support. The two top-leading wheels of the drive section feature clutches that can be disengaged prior to loading. This allows the top wheels to rotate freely as the vessel is loaded, preventing any damage to the transmission. Whether the vessel is lowered centrally or onto one wheel first, the system ensures that no harm is caused, regardless of the vessel’s weight.

Driven Type : Electric

Condition : New

Automatic Grade : Semi Automatic

Application : Industrial

Voltage : 230-380V

Type : Self Aligning Rotator

Country of Origin : India

Brand Name : Innovic

...more

75MT Conventional Welding Rotator

810,000 - 850,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: Conventional Rotators Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle. Conventional Rotators: Built for Heavy-Duty Applications INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers. Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements. The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously. If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

Brand Name : Innovic

Driven Type : Electric

Color : Blue

Condition : New

Feature : Easy To Operate, Robust Construction

Voltage : 230-380V

Country of Origin : India

...more

60MT Self Aligning Welding Rotator

720,000 - 760,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: INNOVIC's self-aligning rotators automatically adjust to the diameter of the vessel as it is loaded. This eliminates the need for manual adjustments, making them ideal for handling a wide range of vessel sizes effortlessly. Self-Aligning Rotators: Precision and Efficiency INNOVIC’s self-aligning rotators are designed with trunnion brackets that automatically adjust the wheel alignment when transitioning between different diameters, eliminating the need for any manual adjustments. Each section of the rotator supports the vessel or job at four points, providing superior traction. On machines with capacities ranging from 3 tonnes to 500 tonnes and above, all four wheels on the drive section are positively driven. This four-point suspension offers a significant advantage, especially when handling thin-walled vessels, ensuring even support. The two top-leading wheels of the drive section feature clutches that can be disengaged prior to loading. This allows the top wheels to rotate freely as the vessel is loaded, preventing any damage to the transmission. Whether the vessel is lowered centrally or onto one wheel first, the system ensures that no harm is caused, regardless of the vessel’s weight.

Driven Type : Electric

Color : Blue

Condition : New

Automatic Grade : Semi Automatic

Application : Industrial

Type : Self Aligning Rotator

Country of Origin : India

Brand Name : Innovic

...more

60MT Conventional Welding Rotator

720,000 - 750,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: Conventional Rotators Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle. Conventional Rotators: Built for Heavy-Duty Applications INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers. Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements. The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously. If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

Driven Type : Electric

Color : Yellow

Condition : New

Application : Industrial

Feature : Easy To Operate, Robust Construction

Voltage : 230-380V

Country of Origin : India

Brand Name : Innovic

...more

50MT Self Aligning Welding Rotator

630,000 - 660,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: INNOVIC's self-aligning rotators automatically adjust to the diameter of the vessel as it is loaded. This eliminates the need for manual adjustments, making them ideal for handling a wide range of vessel sizes effortlessly. Self-Aligning Rotators: Precision and Efficiency INNOVIC’s self-aligning rotators are designed with trunnion brackets that automatically adjust the wheel alignment when transitioning between different diameters, eliminating the need for any manual adjustments. Each section of the rotator supports the vessel or job at four points, providing superior traction. On machines with capacities ranging from 3 tonnes to 500 tonnes and above, all four wheels on the drive section are positively driven. This four-point suspension offers a significant advantage, especially when handling thin-walled vessels, ensuring even support. The two top-leading wheels of the drive section feature clutches that can be disengaged prior to loading. This allows the top wheels to rotate freely as the vessel is loaded, preventing any damage to the transmission. Whether the vessel is lowered centrally or onto one wheel first, the system ensures that no harm is caused, regardless of the vessel’s weight.

Driven Type : Electric

Condition : New

Automatic Grade : Semi Automatic

Application : Industrial

Type : Self Aligning Rotator

Country of Origin : India

Brand Name : Innovic

...more

50MT Conventional Welding Rotator

630,000 - 680,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: Conventional Rotators Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle. Conventional Rotators: Built for Heavy-Duty Applications INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers. Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements. The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously. If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

Material : Mild Steel

Driven Type : Electric

Color : Blue

Condition : New

Application : Industrial

Feature : Easy To Operate, Low Maintenance, Robust Construction

Voltage : 230 V-380V

Country of Origin : India

Brand Name : Innovic

...more

30MT Self Aligning Welding Rotator

450,000 - 490,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: INNOVIC's self-aligning rotators automatically adjust to the diameter of the vessel as it is loaded. This eliminates the need for manual adjustments, making them ideal for handling a wide range of vessel sizes effortlessly. Self-Aligning Rotators: Precision and Efficiency INNOVIC’s self-aligning rotators are designed with trunnion brackets that automatically adjust the wheel alignment when transitioning between different diameters, eliminating the need for any manual adjustments. Each section of the rotator supports the vessel or job at four points, providing superior traction. On machines with capacities ranging from 3 tonnes to 500 tonnes and above, all four wheels on the drive section are positively driven. This four-point suspension offers a significant advantage, especially when handling thin-walled vessels, ensuring even support. The two top-leading wheels of the drive section feature clutches that can be disengaged prior to loading. This allows the top wheels to rotate freely as the vessel is loaded, preventing any damage to the transmission. Whether the vessel is lowered centrally or onto one wheel first, the system ensures that no harm is caused, regardless of the vessel’s weight.

Brand Name : Innovic

Driven Type : Electric

Condition : New

Automatic Grade : Semi Automatic

Application : Industrial

Voltage : 230-380V

Country of Origin : India

...more

30MT Conventional Welding Rotator

450,000 - 480,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: Conventional Rotators Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle. Conventional Rotators: Built for Heavy-Duty Applications INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers. Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements. The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously. If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

Material : Mild Steel

Driven Type : Electric

Color : Yellow

Condition : New

Automation Grade : Semi-Automatic

Application : Industrial

Feature : Easy To Operate, Robust Construction

Voltage : 230-380V

Country of Origin : India

Brand Name : Innovic

...more

300MT Conventional Welding Rotator

2,430,000 - 2,450,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: Conventional Rotators Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle. Conventional Rotators: Built for Heavy-Duty Applications INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers. Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements. The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously. If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

Brand Name : Innovic

Driven Type : Electric

Condition : New

Feature : Easy To Operate, Low Maintenance, Robust Construction

Voltage : 3800-440V

Warranty : 1year

Country of Origin : India

...more

300MT Self Aligning Welding Rotator

2,430,000 - 2,450,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: INNOVIC's self-aligning rotators automatically adjust to the diameter of the vessel as it is loaded. This eliminates the need for manual adjustments, making them ideal for handling a wide range of vessel sizes effortlessly. Self-Aligning Rotators: Precision and Efficiency INNOVIC’s self-aligning rotators are designed with trunnion brackets that automatically adjust the wheel alignment when transitioning between different diameters, eliminating the need for any manual adjustments. Each section of the rotator supports the vessel or job at four points, providing superior traction. On machines with capacities ranging from 3 tonnes to 500 tonnes and above, all four wheels on the drive section are positively driven. This four-point suspension offers a significant advantage, especially when handling thin-walled vessels, ensuring even support. The two top-leading wheels of the drive section feature clutches that can be disengaged prior to loading. This allows the top wheels to rotate freely as the vessel is loaded, preventing any damage to the transmission. Whether the vessel is lowered centrally or onto one wheel first, the system ensures that no harm is caused, regardless of the vessel’s weight.

Driven Type : Electric

Condition : New

Automatic Grade : Semi Automatic

Application : Industrial

Voltage : 230-380V

Type : Self Aligning Rotator

Country of Origin : India

Brand Name : Innovic

...more

20MT Self Aligning Welding Rotator

360,000 - 380,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: INNOVIC's self-aligning rotators automatically adjust to the diameter of the vessel as it is loaded. This eliminates the need for manual adjustments, making them ideal for handling a wide range of vessel sizes effortlessly. Self-Aligning Rotators: Precision and Efficiency INNOVIC’s self-aligning rotators are designed with trunnion brackets that automatically adjust the wheel alignment when transitioning between different diameters, eliminating the need for any manual adjustments. Each section of the rotator supports the vessel or job at four points, providing superior traction. On machines with capacities ranging from 3 tonnes to 500 tonnes and above, all four wheels on the drive section are positively driven. This four-point suspension offers a significant advantage, especially when handling thin-walled vessels, ensuring even support. The two top-leading wheels of the drive section feature clutches that can be disengaged prior to loading. This allows the top wheels to rotate freely as the vessel is loaded, preventing any damage to the transmission. Whether the vessel is lowered centrally or onto one wheel first, the system ensures that no harm is caused, regardless of the vessel’s weight.

Brand Name : Innovic

Driven Type : Electric

Condition : New

Automatic Grade : Semi Automatic

Application : Industrial

Voltage : 230-380V

Country of Origin : India

...more

10MT Self Aligning Welding Rotator

310,000 - 360,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: INNOVIC's self-aligning rotators automatically adjust to the diameter of the vessel as it is loaded. This eliminates the need for manual adjustments, making them ideal for handling a wide range of vessel sizes effortlessly. Self-Aligning Rotators: Precision and Efficiency INNOVIC’s self-aligning rotators are designed with trunnion brackets that automatically adjust the wheel alignment when transitioning between different diameters, eliminating the need for any manual adjustments. Each section of the rotator supports the vessel or job at four points, providing superior traction. On machines with capacities ranging from 3 tonnes to 500 tonnes and above, all four wheels on the drive section are positively driven. This four-point suspension offers a significant advantage, especially when handling thin-walled vessels, ensuring even support. The two top-leading wheels of the drive section feature clutches that can be disengaged prior to loading. This allows the top wheels to rotate freely as the vessel is loaded, preventing any damage to the transmission. Whether the vessel is lowered centrally or onto one wheel first, the system ensures that no harm is caused, regardless of the vessel’s weight.

Brand Name : Innovic

Driven Type : Electric

Color : Blue

Condition : New

Application : Industrial

Voltage : 230-380V

Country of Origin : India

...more

100MT Self Aligning Welding Rotator

1,260,000 - 1,280,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: INNOVIC's self-aligning rotators automatically adjust to the diameter of the vessel as it is loaded. This eliminates the need for manual adjustments, making them ideal for handling a wide range of vessel sizes effortlessly. Self-Aligning Rotators: Precision and Efficiency INNOVIC’s self-aligning rotators are designed with trunnion brackets that automatically adjust the wheel alignment when transitioning between different diameters, eliminating the need for any manual adjustments. Each section of the rotator supports the vessel or job at four points, providing superior traction. On machines with capacities ranging from 3 tonnes to 500 tonnes and above, all four wheels on the drive section are positively driven. This four-point suspension offers a significant advantage, especially when handling thin-walled vessels, ensuring even support. The two top-leading wheels of the drive section feature clutches that can be disengaged prior to loading. This allows the top wheels to rotate freely as the vessel is loaded, preventing any damage to the transmission. Whether the vessel is lowered centrally or onto one wheel first, the system ensures that no harm is caused, regardless of the vessel’s weight.

Brand Name : Innovic

Driven Type : Electric

Condition : New

Automatic Grade : Semi Automatic

Application : Industrial

Country of Origin : India

...more

100MT Conventional Welding Rotator

1,260,000 - 1,280,000 Per Set

1 Set (MOQ)

Welding rotators are an essential and versatile piece of positioning equipment in any fabrication workshop. INNOVIC offers a wide range of welding rotators, each designed for specific applications. These machines include the following types: Conventional Rotators Conventional rotators consist of two sets of adjustable rollers. The rollers can be adjusted manually or through a lead-screw and ratchet mechanism to accommodate different vessel diameters. This allows for smooth transitions between varying sizes without much hassle. Conventional Rotators: Built for Heavy-Duty Applications INNOVIC’s conventional rotators are engineered with capacities ranging from 1 tonne to 2000 tonnes. The frame features a robust, fabricated design that is precision-machined both on the top and underneath to ensure perfect alignment. Both the drive and idler frames come equipped with durable, fabricated and machined wheel brackets that securely support the axles and bearings of the rollers. Depending on the capacity, the rotators are fitted with either all-polyurethane wheels with overload protection or all-steel wheels to handle different load requirements. The chassis, or base structure, of the rotator is carefully designed and fabricated to support the weight of the vessel or job, with an additional margin for shock loads. This is crucial for preventing any frame distortion that could lead to misalignment of the rollers. The drive section experiences the highest strain during the loading process, as it is difficult for a crane operator to perfectly position the vessel so it contacts both roller sets simultaneously. If the workpiece contacts one set of rollers before the others, the initial roller experiences a full shock load, which places significant force on the drive system. To counter this, INNOVIC rotators are designed with a substantial overload margin to absorb these shock loads effectively, ensuring safe and smooth operation.

Brand Name : Innovic

Driven Type : Electric

Color : Blue

Condition : New

Application : Industrial

Feature : Easy To Operate, Robust Construction

Country of Origin : India

...more

Precision Machining

INNOVIC TECHNOLOGY uses the latest technology for machining, CNC turning, drilling, grinding and milling. Special processes such as thread rolling, deep hole drilling, Wire cut machining and EDM are used throughout the production. CUSTOM MANUFACTURING AND MACHINING All manufacturing processes, materials procurement, subcontracting of work and inspection services are monitored throughout the entire production. We pride ourselves on our custom manufacturing services. Through close association with the customer, we create parts based on individual requirements, as well as industry standards and documentation. Customers are also able to supply materials or semi-finished products. SPECIALTY FASTENERS Production of specialty fasteners utilizes a wide range of steels from carbon steels to high alloy materials. Fasteners are made from M4 and up. These products are widely used for heat- and pressure-exposed joints. We also provide surface finishes per clients’ requirements.

...moreOpening Hours