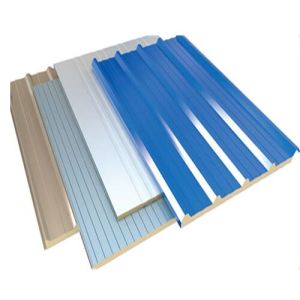

cold storage panel

Get Price Quote

FR-A840-00052-2-60 Mitsubishi Variable Frequency Drive

32,753 - 45,321 Per piece

1 Piece (MOQ)

Best Deals from Instrumentation Equipment

PUF Panels

1,100 Per Square Meter

Puf Panel

1,400 Per Square Meter

Instrumentation Cables

Get Price Quote

Instrumentation Cables, we offer, are made using the best quality material. Also, we entertain the specific needs of the clients and produce these Instrumentation Cables accordingly. We are an ISO Certified Manufacturer and Exporter of the Instrumentation Cables. We provide these Instrumentation Cables at the market leading rates. Why Our Instrumentation Cables? Made using cutting-edge technology Customized solutions availableEconomically priced Uses Of Different Cables The connection and interfacing of most data transmission equipment can be easily affected using either screened or unscrewed twisted pair cables or coaxial cable. For microcomputers, which use low speed data transmission over short distances, Unscreened Multicore or Multi-pair Cables can be used. For the Interconnection of Data Processor, instruments and microcomputers where signal interface is a consideration, cables are generally screened. Minicomputers need medium speed transmission of data, and for these, interfaces with screen twisted pair cables are suitable. When signal speed is low, a braid screen is sufficient but for higher speeds a foiled screen or composite foil and braid screen is more suitable. One can use individually screened pairs to diminish the effect of cross talk, resultantly making possible smooth transmission over long distances. Components Conductor : Conductor material is Copper. It may be bare or tin coated to minimize oxidation and facilitate soldering. Conductors may be stranded or solid type. For higher cross section generally stranded type construction is preferred.Insulation : Insulation material depends upon the electrical and mechanical properties desired and the environments. The most common material is Polyethylene and PVC.Shields : Shields is provided to prevent harmful electrostatic interface. These are three basic reasons for providing an electrostatic shield in a cable. The first, and the most common, reason concerns the need to keep external electrical disturbances from affecting the signal in the cable. The second reason is to prevent the signal in the cable from being detectable at location other than at the cable ends. The third reason is the combination of the first two. It is the elimination of unwanted transfer of signals between circuits in the same cable, commonly called cross talk. Two types of shields as given below are commonly used. Braided Copper Wire Shield : Braided shields are reasonably flexible, quite durable and offer a good balance of shielding properties. The drawbacks in braided shields are difficulty in terminating higher cable dimensions and cost. The practical limits of coverage are approach 96%. Aluminum Laminated Mylar Tape Shields : It consists of a laminate of rolled aluminum foil, which is bonded with a high strength adhesive to the mylar film. The tape is applied spirally of longitudinally and provides total (100%) electrostatic shielding. An un-insulated conductor, drain wire is provided in intimate contact with aluminum side of the tape for the ease of shielded termination. The drain wire may be of solid tinned copper or stranded tinned copper and serves triple purpose. Provides easy and suitable grounding of the mylar-aluminum shield. Acts as conductors in relay control of annunciator circuits. Drains the accumulated static charges from the mylar-aluminum shield to ground.Sheath : PVC compound is generally used for sheathing purpose. It may have additional fire retardant (FR) or fire retardant low smoke (FRLS) properties. Polyethylene sheath is recommended for low temperature application and aromatic hydrocarbon surrounding. However, polyethylene sheath does not have flame retarding properties.Armor : Armoring is provided for mechanical protection and may be either of galvanized round steel wire or galvanized flat steel strips.Governing Specifications : BS - 5308 (Part - 1 & 2), VDE 0815, IS - 1554 (Part - 1), in general and customers specifications

WPC Board

60 - 250 Per Sq. Ft.

100 Nos (MOQ)

PUF Panels

Get Price Quote

Automotive Sheet Metal Components

Get Price Quote

We are engaged in offering a comprehensive range of Sheet Metal Components for Automobile to the clients. These products are manufactured using high-grade steel, which is sourced from the reputed vendors in the market. To meet the variegated demands of our clients, we offer these products in various dimensions. Before the final shipment, these products are checked on different parameters by our quality inspectors.

PLC Based Automation Panel

Get Price Quote

We are providing PLC Based Automation Control Panel Solution from Designing to End commissioningProviding solution for Flame proof, Explosion proof and Weather proof control panel.We are using the Latest PLC and HMI technologies to provide best solution to our customer.We are providing Hardware selection to end commissioning support for Small scale PLC System to Complex PLC based System requirements.We are providing full support for PLC, HMI, SCADA and AC Drive based Simple to Complex Automation Panel Solution.We are providing the Servo Based Motion Control Automation Solution.

Puf Insulated Panels

1,300 Per Square Meter

We are the leading manufacturers, exporters and supplier of this products.

odor control systems

Get Price Quote

Odor control systems the Quality of Water and Aqueous solutions. HACH is your resource for expert answers, outstanding support, and reliable, easy-to-use products.

RIP BUSBAR SYSTEMS

Get Price Quote

Mgc - a century of electro-technical tradition mgc moser-glaser ag, switzerland with it's 50 years of excellence and uncontested expertize in the field of rip insulations brings to you a revolutionalry ehv busbar systems ranging up to 170 kv 8000 a. Busbar systems offer a compact and safer solution comapared to cable or conventional bus duct solutions. Boasting of a large clientele and renowned for its world class bushings mgc is a technology leader in the sector.

Copper Bus Bar

Get Price Quote

In annealed (o), half hard (HB) and full hard (HD) condition In kilograms per meter (1 meter = 39.37 inches = 3.25 feet) Width - 20 mm to 150 mm 1. with Sharp Edges Thickness - 5 mm to 25 mm 2. with Round Edges 3. with Full Radius

Electrical Panel

Get Price Quote

Jay Jagannath Air Equipments is one of the recognized names in manufacturing of Electrical Panel. These find their application in commercial buildings, hospitals, industries, dairies, research laboratories etc.

Automotive Products

Get Price Quote

We are offering latest products of automotive products for all age man & woman.

Electric Panel Board

Get Price Quote

Electric Panel Board, Meter Boxes, Transformer Tanks

Emission Control Systems

Get Price Quote

Our unparalleled innovation and expertise enables us to closely examine your needs, listen to your challenges and explore the most suitable technology to achieve the agreed-upon performance of your emission control solution.

Water Softening Plant

Get Price Quote

Water softening is the removal of calcium, magnesium, and certain other metal cations in hard water. The resulting soft water requires less soap for the same cleaning effort as soap is not wasted mopping up calcium ions. Soft water also extends the lifetime of plumbing by reducing or eliminating scale build-up in pipes and fittings. Water softening is usually achieved using lime softening or ion-exchange resins. The Process: The heart of a water softener is a mineral tank. It’s Filled with small polystyrene beads, also known as resin or zeolite. The beads carry a negative charge. Calcium and magnesium in water both carry positive charges. This means that these minerals will cling to the beads as the hard water passes through the mineral tank. Sodium ions also have positive charges, albeit not as strong as the charge on the calcium and magnesium.When a very strong brine solution is flushed through a tank that has beads already saturated with calcium and magnesium, the sheer volume of the sodium ions is enough to drive the calcium and magnesium ions off the beads. Water softeners have a separate brine tank that uses common salt to create this brine solution. In normal operation, hard water moves into the mineral tank and the calcium and magnesium ions move to the beads, replacing sodium ions. The sodium ions go into the water. Once the beads are saturated with calcium and magnesium, the unit enters a 3-phase regenerating cycle. First, the backwash phase reverses water flow to flush dirt out of the tank. In the recharge phase, the concentrated sodium-rich salt solution is carried from the brine tank through the mineral tank. The sodium collects on the beads, replacing the calcium and magnesium, which go down the drain. Once this phase is over, the mineral tank is flushed of excess brine and the brine tank is refilled. CHEMICAL REACTION DURING SOFTENING PROCESS :- Ca (HCO3)2 + Na2 R = RCa + NaHCO3CaSO4 + Na2 R = RCa + Na2SO4MgCl2 + Na2R = RMg + NaCl REGENERATION PROCESS :- Raw water will continue to get softened till the resin gets exhausted. Bringing back the resin to it original form is called regeneration. Softener resin is regenerated by sodium chloride- Nacl (Common salt) solution. The common salt solution is kept in the regeneration tank. During the regeneration process, salt solution is injected by the ejector tube into softener. The Nacl (salt solution) replaces ca, Mg (Hardness) from the resin, the regeneration is done every day or every few days or every week depending upon the usage and design of the water softener plant. CHEMICAL REACTION DURING REGENERATION PROCESS :- RCa + NaCl = RNa + CaCl2RMg + NaCl = RNa + MgCl2 Application: Boiler Feed Cooling Tower Make-Up Air Conditioning Plant Textile Processing Beverage Production Hospitals, Hotels, Laundries etc. Product Details ES Treatment Plant Effuent Treatment Plant DM Water Treatment Plant Ceramic Membrane System Industrial RO Plant ETP Membrane System MBBR Sewage Treatment Plant Activated Carbon Filter Pressure Sand Filter Neno Filtration Ultra Filtration Water Softening Plant Our Document.PDF Get Touch With Us You can also send us an email and we’ll get in touch shortly, or Call our Number : - ( 0265)2417347/2426826. Locate Us

Frequency Inverter

Get Price Quote

Frequency Inverter

Solar Panel

Get Price Quote

Different Solar Modules of different capacity is available.

Electric Control Panel

Get Price Quote

switchboards

Emission Control Systems

Get Price Quote

For over a century, GEA has been a world leader in development, design and installation of emission reduction systems and technologies for customers in the process industries. Our unparalleled innovation and expertise enables us to closely examine your needs, listen to your challenges and explore the most suitable technology to achieve the agreed-upon performance of your emission control solution. Not only does this provide lasting benefits for the environment, but keeps you competitive and compliant, now and for the future.

DG Synchronization Panel

Get Price Quote

DG Synchronization Panel, relay panels, automotive painting plant

Automotive Products

Get Price Quote

Automotive Products, Clutch Plate Hubs, Bearing Housings, retainer plates

Automotive Sheet Metal Components

Get Price Quote

Automotive Sheet Metal Components, Press Tools, Wire Cut Machine work

panel boards

Get Price Quote

panel boards, manpower solution, sales outsourcing services

Puf Insulated Panels

Get Price Quote

Puf Insulated Panels, Frp Sheet, Frp Grating, interior designers service

Automation and Control Systems

Get Price Quote

Automation and Control Systems, Chillers and Heat Pumps

Control Panel

Get Price Quote

Panel Box, Other Products

PH & ORP Sensor

Get Price Quote

PH & ORP Sensor, Aire-02 Tank Mixers, Submersible Mixers With Direct Drive