Fully Automated Liquid Extraction System

Get Price Quote

10 pieces (MOQ)

liquid Extraction Unit

Get Price Quote

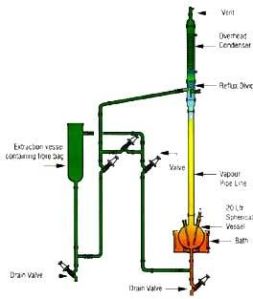

Liquid extraction, sometimes called solvent extraction, is the separation of constituents of a liquid solution by contact with another insoluble liquid. The unit described here is for a semi-batch operation. The liquid to be extracted is poured into an extraction vessel. Solvent is boiled in a reboiler vessel and condensed in an overhead condenser, the condensed liquid collected in a reflux divider and passed through pipework to the extraction vessel. The pipework incorporates valves in order that the solvent can enter the extraction vessel at either the base of the top, depending on the relative densities of the solvent and liquid to be extracted. The solvent and the extracted liquid pass back to the reboiler and the process is repeated until the extraction is complete. The extraction vessel is then drained and the solvent evaporated from the reboiler vessel and collected in the extraction vessel enables the two liquids to be drained from their respective vessels. The unit is available in vessel sizes of 10, 20, & 50L and is suitable for operation under atmospheric pressure.

Best Deals from Liquid Extraction Systems

liquid Extraction Unit

Get Price Quote

10 Set(s) (MOQ)

We are offering liquid extraction unit. liquid extraction, sometimes called solvent extraction, is the separation of constituents of a liquid solution by contact with another insoluble liquid. The unit described here is for a semi-batch operation. the liquid to be extracted is poured into an extraction vessel. Solvent is boiled in a reboiler vessel and condensed in an overhead condenser, the condensed liquid collected in a reflux divider and passed through pipework to the extraction vessel. The pipework incorporates valves in order that the solvent can enter the extraction vessel at either the base of the top, depending on the relative densities of the solvent and liquid to be extracted. The solvent and the extracted liquid pass back to the reboiler and the process is repeated until the extraction is complete. The extraction vessel is then drained and the solvent evaporated from the reboiler vessel and collected in the extraction vessel enables the two liquids to be drained from their respective vessels. the unit is available in vessel sizes of 10, 20, & 50l and is suitable for operation under atmospheric pressure.

Liquid Extraction Plant

125,000 - 351,000 Per Piece

1 Set (MOQ)

UD Offers different Extraction solutions Mixer Settler Mixer-settlers, both as stand-alone and as in-column type, are offered for special applications. Due to the pump-mix turbine no additional feed pumps are required in most cases. Continuous Packed Bed Liquid Liquid Extraction The key benefit of a packed column is the high throughput which leads to small column diameters. Together with specially adapted liquid distributors, our structured packing provides the best extraction performance Agitated Extraction Column In applications with high mass transfer and/or changing physical properties, this is the column of choice. The compartment geometry can be adapted to compensate for changing conditions resulting in a constant high column performance. The main features are the special mixing turbines and the perforated partition plates. All Items can be coupled with Computers for Control and Data Acquisition through SCADA. UD Offers Glass Rotating Disc Extractors The Rotating Disc extractor is a continuous, counter-current, liquid-liquid extractor, used for extraction of product or impurities from aqueous or organic streams by extraction with suitable organic solvent or water. The technique with its excellent repeated mixing and settling feature at each stage creates an extraction capability that is equivalent of several washings in a batch kettle. Solvent consumption can be reduced almost to 50% and power consumption to 70% than the batch operation. Simple and non-laborious operation with use of simple automation makes it possible to get consistent results.Used for extraction of product or impurity from bulk drug reaction mass, impurity removal from agrochemical product streams, extraction of product from mass stream in plant extract stream, biochemicals, recovery of product or toxic component from waste water stream Agitated Extraction is Practically Universally Suitable for all type of Liquid Liuid Extraction.Limiting Condition is minimum density difference 0.05 Kg/M3 between both phases and a not to form Stong tendancy to form stable emulsion in order to allow a smooth agitation In applications with high mass transfer and/or changing physical properties, this is the column of choice. The compartment geometry can be adapted to compensate for changing conditions resulting in a constant high column performance. The main features are the special mixing turbines and the perforated partition plates. Advantages : Adaption of Compartment and Agitator Geometry to the specific Product and Operating Condition The Optimal Droplet Size can be adjusted ed by varying Agitation Speed Insensitive to Solids In applications with high mass transfer and/or changing physical properties, this is the column of choice. The compartment geometry can be adapted to compensate for changing conditions resulting in a constant high column performance. The main features are the special mixing turbines and the perforated partition plates.

liquid Extraction Unit

Get Price Quote

We offer high quality liquid extraction unit that is designed for liquid-to-liquid extraction as a means of separation. The liquid extracted is treated with the solvents of different density. The unit is supplied with solvent feed either from top of from bottom, or with common arrangement. Moreover, we are identified as one of the most reputed mini liquid extraction unit exporters, based in india.