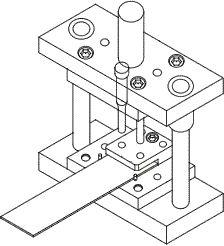

stamping tool

Progressive Die

MEW is committed to provide the best quality die/tooling for our customers’ product. With more than 30 years of experience in sound manufacturing methods and procedures, we are capable to accurately check and document every tooling component and sample piece part. These results into high-caliber tooling, that ensures long production runs, minimum down-time and fully interchangeable tooling. Some of the die/tool that we offer our customers Progressive Die-Blanking Die, Bending Die, Embossing Die, Compound Die, Cut-off Die, Coining Die, Forming Die, Piercing Die, Side Cam Die Advantage of Progressive Die Low production cost for components Good consistency and quality stability Less time to market Heavy tonnage quantity Advantage of simple stamping Die Low cost for die design and manufacturing Shortest delivery period Suitable for experimenting something new

...more

Investment Castings products

MEW is the leading provider of precision Investment Castings products. We offer you tooling, heat treat, assembly, machining, powder coating and other finishing services for precision investment casting at unmatched lead times. Our �investment casting� process at a glance The first step in the investment casting process is to produce a wax replica of the desired part. After producing wax replica in a die; they are �wax welded� to a central sprue or cluster to facilitate pouring. The assembled sprue is then dipped into ceramic slurry and it is coated with ceramic sand to build sufficient shell strength. These shells built sprue is then de-waxed by rapidly heating in a furnace leaving behind the perfect shell cavity. The shells are then hardened to make shells interior into smooth and strong ceramic material. The hot sprues are poured immediately, and after cooling the sprues are cutoff from central sprue. The final finished components get by grinding the residues.

...more

die tools

Die/Tool manufacturing MEW is committed to provide the best quality die/tooling for our customers� product. With more than 30 years of experience in sound manufacturing methods and procedures, we are capable to accurately check and document every tooling component and sample piece part. These results into high-caliber tooling, that ensures long production runs, minimum down-time and fully interchangeable tooling. Some of the die/tool that we offer our customers Progressive Die-Blanking Die, Bending Die, Embossing Die, Compound Die, Cut-off Die, Coining Die, Forming Die, Piercing Die, Side Cam Die Advantage of Progressive Die Low production cost for components Good consistency and quality stability Less time to market Heavy tonnage quantity Advantage of simple stamping Die Low cost for die design and manufacturing Shortest delivery period Suitable for experimenting something new

...more

Die Stamping Metal Components

We have state of the art manufacturing facility that is equipped with all the latest machines and equipment used to manufacture precise range of high tonnage die stamping metal components of various shapes and sizes as per customers� requirement. We have expertise in mass production of customized, engineered and special purpose sheet metal based components. We are manufacturing world class Die Stamping Metal Components of Stainless Steel, brass and copper as well as mild steel. Advantages of MEW In-house customer tooling that is used to produce stamping components, is maintained by replacing worn-out or broken punches, die sharpening or anything that is required to produce components strictly as per customer drawings. Whether MEW is making your first production part or the millionth, quality is consistent. Some of the products that we have offered our customers in various shapes and sizes with different material as required for specific application

...more

blanking die

Stamping Die

Progressive Tool

Investment Casting

Cutting Die

Be first to Rate

Rate ThisOpening Hours