Three Stage water Ejector

Three Stage Ejector is similar in construction as of Single Stage Ejector, but having intermediate condensers. Three Stage Ejector comprises of Booster Ejector, Booster condenser and a Two Stage Ejector. And Two Stage Ejector consists of a high vacuum ejector, a inter condenser and a low vacuum ejector. This system will give higher vacuum and can handles larger quantity of condensable vapors. Gas or Gas vapor mixture is discharged from the first stage into the condenser where the operating steam is condensed and gases are cooled. The cooled gases are then entrained by the second stage and discharged into the second inter condenser. Here, the steam used in the second stage is condensed. The gases are finally entrained by the third stage and discharged to atmosphere. Absolute Pressure Range Vacuum from 5 MM HG Absolute to 15 MM HG Absolute

...more

Surface Condenser

New field surface condensers are planned to condense turbine exhaust steam in power generating or mechanical drive applications. The condenser produces a vacuum at the turbine discharge raising the overall cycle efficiency. New field condensers have proven to be reliable and are chosen for applications all over the world, including installations in chemical processing plants, refineries, marine applications, and power generation facilities. A variety of fabrication in Chemical processing plants,refineries,Marine applications and power Generation Units.New Field Provides Varieties of fabrication options, materials, and configurations are employed to satisfy today's challenging technical requirements.

...more

steam jet ejectors

The system is the assembly of two units whose construction is similar to single stage with inter condenser (direct contact type or surface type). Steam of the first stage is expanded through nozzle entrains the air or other gases and discharges them to diffusers at a higher pressure in the condenser. The discharge from the first stage will then directed to condenser which reduces volume of discharge gases. These gases turn discharged with the help of second stage ejector. The ejector is required to be placed at sufficient height to drain the ejector condenser barometrically. If barometric installation is not possible then an extraction pump is provided to drain the condenser in vacuum. The discharge of exhaust steam and entrained gases is directed to the atmosphere or can be condensed by an after condenser or lead to a water tank if required.

...more

Static Mixer

power plant surface condenser

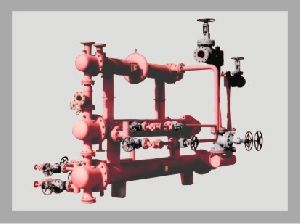

GAS SKIDS SYSTEM

1. New Field Industries has been providing measurement solutions to the world's Oil, Gas and Process Industries for over 10 years with over 50 metering, filtration and pressure control skid systems reliably operating in countries worldwide. 2. As one of the few fully independent systems integrators in the Oil and Gas Industry, we offer solutions with the best and most recent technology to meet project requirements. 3. Our experience in all types of high accuracy metering from fiscal/custody systems for Natural Gas and crude oil, through dry gas metering packages, is hard to match. 4. We specialize in designing Modular skids on structural base for proper transportation and maintenance. 5. We have specialization in fabrication of pressure piping. Newfield can carry fabrication for piping which includes entire process range for the Natural Gas industries. This include High Pressure piping (#150 to #2500), Low temperature applications (A333 Gr. 6, A350LF2) and on request special alloy. 6. All necessary National and international standards are followed and can be certified for BS10204 3.1 on request. Experience & Skill Conventional project procedures are complemented by innovative work practices including integrated Team working and Open Book Partnering.In offshore and onshore production facilities, pipeline operations, terminals, refineries and power generation stations, NewField packages set the standard.Complete with associated equipment for control, analysis, filtration, pressure and flow regulation, all NewField systems are designed to meet national and international standards. Integrated and Neutral Solution Provider Unlike many metering system manufacturers, NewField is completely independent and not tied to specific equipment vendors. This enables us to supply the most competitive and objective solution to meet the customer's requirements.The project reference list displays how NewField has promoted the constant advances in metering technology, improving performance and increasing value for its clients. Filtration System Newfield has fabricated filters for Natural Gas application under ASME SEC VIII. Based on the application and process data Newfield can design and suggest suitable filter cartridges.Necessary instrumentation monitoring and control can be implemented. Differential pressure transmitters, Automatic condensate drainage, Level control and Monitoring are few applications where Newfield has proven solutions.Newfield understands design concepts for lesser operation and maintenance cost. Newfield can offer Quick opening closure for filters from many of reputed vendors worldwide. We also provide solutions for pressure safety based on process parameters and system requirements. Newfield strength also lies in designing of maintenance platforms and structure for a modular design of skid which helps online maintenance. Metering System Newfield has fabricated skids for all measuring principles like Orifice, Turbine, Ultrasonic and Corriolis meters. Our design group understands different stringent requirements under AGA and ISO standards (few to mention AGA3, 7, 9, 11). We carry out honing for meter runs to suits the requirement of standards. We seamlessly integrate the mechanical and instrumentation work on the modular skids. We carryout instrumentation work like cable tray laying, junction box supports, installation of transmitters and instruments etc. Pressure Reduction Skid Offering various solutions for numerous processes in upstream and downstream Oil and Gas industries is always a tricky issue. Newfield offers proven redundant active monitor pressure control system to suit client’s requirement. High quality products are used to support Newfield philosophy of Safety First. Monitoring and control system are offered for both local and remote systems. Heating & Letdown skid Newfield fabricates vessels for water bath heaters. Based on client’s requirement, Newfield integrates the third party control system to offer a complete solution for the heating skid. A bypass skid before pressure reduction can be offered to make the Gas line operational without waiting for the main heating skid. The heating skid then can be integrated online.

...more

gas metering skid

Condenser Four Stage water Ejector

Four Stage Ejector is having construction and working similar to Single Stage, Two Stage & Three Stage Ejector. When ejector is to be installed at low ambient temperature area, primary booster should be steam jacketed to prevent building up of ice on the diffuser internal bore. Sometimes both primary and secondary boosters are completely jacked to avoid deposition of product inside the ejector. The Four Stage Ejector consists of following components: » Primary Booster Ejector » Secondary Booster Ejector » Booster Condenser » Vacuum Ejector » Inter Condenser » Low vacuum Ejector

...more

Five Stage Steam Jet water Ejectors,Six stage Steam Jet water Ejectors

Five stage and six stage ejectors are designed for absolute pressure in Micron Range. The arrangement of these ejectors is similar to the four stage ejector with additional one or two non condensing stages. Special Precautions while measuring low Absolute Pressures » Do not use spring type vacuum Gauges » Ensure that the guage tubes are clean and free from contamination » Ensure that the guage liquid is clean and free from contamination » Barometer should be located near mercury manometer » Use a suitable macleod gauge with dry mercury and clean ice freezing trap to measure absolute pressure below 1 mm Hg.

...more

de super heater

air ejector

Heat Exchanger

jet ejector

Water Jet Ejector

Scrubber

educator

siphons

thermo compressors

Silencer

Heaters

mixtures

Pressure Vessels

Be first to Rate

Rate This