GBRH - 600

2,000,000 - 2,500,000 Per No

1 Unit (MOQ)

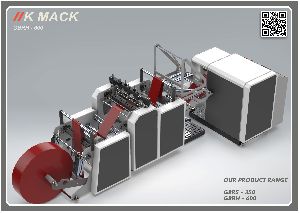

HEAVY DUTY CENTER SEAL POUCH MAKING MACHINE

Get Price Quote

CSP-501 Ultima is a multi-purpose center seal pouch making machine that can convert a lay flat sheet suitable for co-extruded PE film and laminated film PE/PET, PET/ALU, and BOPP-PE. There is also a fin type center seal option for PET/PE laminated film, lap type seal for PE, and co-extruded film which can manufacture heavy duty center seal pouches. The additional skip function also allows you to manufacture long pouches. This high-speed machine runs at a top speed of 80 cycles/min. The pouches manufactured with these machines are recyclable! FEATURES > Shaftless unwind system > Electronic Web Guide system on unwind > Indexing by Servo Motor > Center Seal by reciprocating system operated by servo system > Individual servo system for each cross seal & cooling stations > Auto conveyor system for bag collection > Air-conditioned temperature controlled panel for all electrical components & drives

Best Deals from Pouch Making Machine

Pouch Making Machine

Get Price Quote

We are offering pouch packing machine. filling capacity: as per required filling speed: 1000 to 4000 pouch /hr control: plc control mode of operation: pneumatic weight accuracy: 0.5% of set volume packing materials: laminated films machine weight: 450kg dimension: 1000w × 950l × 82450h power: 220v single phase or 420 three phase compressed air requirement: 6cfm with 6 bar pressure available in variety of models: 0.5g to 10g, 5g to 50g, 10g to 100g, 50g to 250g, 100g to 500g. features: tailor made to suit specific requirement. plc controlled machine with lcd display & tactile keyboard. built in self fault diagnosis systems. password protection for settings. minimum maintenance. if no material machine stop (optional). batch cutting device (optional). epoxy powder coated structure. high filling accuracy. weight adjustment though thumb switch keypad. all contacts parts ss 304 with mirror finish.

Pouch Making Machine

Get Price Quote

Silent Features • Powder Coated Machines having solid structure for long term operation. • Machines is operated by Imported Servo System for high speed and accuracy. • Use of Imported PLC and MMI. Size and count set digitally on MMI. • Mark sense alarm and cut off system reduces wastage if variation in printing. • High speed, Over current, Over load, Low Voltage alarm and cut off system. • An isolation transformer is provided for Servo System. • User friendly Center Sealing System. • Horizontal Mounting of Three Side Seal Roll helps to handle heavy roll easily. • Total Three Unwind Stands enable to run TWO rolls for Three Side Seal. • Side Gusset for Center Seal as standard attachment. • Separate Temperature Controller for Center Seal and Three Side Seal. • Speed up to 150pouch/min. • AC Drives for Main and Unwind. Optional Attachment • Incense Stick Sealer with Perforation with Auto Cut • On Line D Punch, Handle Punch, Hanger Punch and V notch

pouch making machines

Get Price Quote

pouch making machines, Flexo Printing Machine, plastic bag making machines

pouch making machines

Get Price Quote

pouch making machines, Flexible Film, Flexographic Printing Machines