Vpi Dry Transformer

1,000 - 10,000 Per piece

1 Set(s) (MOQ)

Special purpose epoxy cast resin transformer moisture proof: complete encapsulation of primary and secondary winding in epoxy resin prevents penetration of moisture into windings. The cast resin offers very good protection against adverse ambient conditions. These transformers can work without disruption of service at 100% humidity. no leakage or pilferage of oil: as cast resin transformers are solidly cast, problem associated with oil filled transformers like oil leakage and pilferage of oil is completely avoided. Hardly inflammable and self extinguishing: due to high quality insulation material the transformer is practically non-inflammable by an electrical arc, special fire protection measures are not required. Impulse strength : contrary to the conventional dry type transformers the cast coil transformers are better in respect of impulse voltage withstand strength. Resistant against temperature fluctuation: the insulation material used is glass fibre reinforced with epoxy resin of class 'f' which can withstand wide temperature variation.

...more

Voltage Stabilizer

100,000 - 500,000 Per Piece

1 Piece(s) (MOQ)

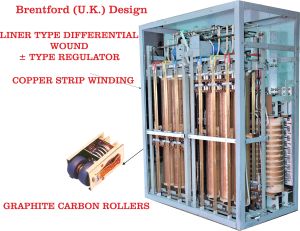

Servo Stabilizer is An Automatic Voltage Regulator, Which Primarily Consists of the Following Features : • Linear, Plus / Minus Type Vertical Rolling Contact Voltage Regulator for Making These Regulators, We Use Heavy Section of Electrolytic Grade Rectangular Copper Strip Instead of Copper Wire in Order to Minimize the Losses & Increase the Efficiency of Equipment. We also Employ Self Lubricating Carbon Roller Assemblies Instead of Ordinary Carbon Brushes that Offers More Reliability and Trouble Free Performance of the Equipment. • double Wound Buck / Boost Type Series Transformer in Our Buck / Boost Transformer, We Make Use of Crgo Lamination to Reduce Iron Losses. the Coils of Buck / Boost Transformer are Wound with Heavy Section of Multi Strips Electrolytic Copper to Minimize Copper Losses to Get Better Efficiency of the Equipment. • electronic Control Circuit and Meter Panel automatic Voltage Controller Usually Consists of Very Simple Electronic Control Voltage Circuit for Monitoring and Controlling Voltage, Repair and Maintenance of Which is Very Easy. the Regulator and Buck / Boost Transformer are Oil Cooled, Placed in Same or Separate Sheet Steel Tanks. These Devices are Provided with Radiators for Effective Cooling. the Coils of Voltage Regulators & Buck / Boost Transformers are Vacuum Impregnated and Oven Dried as per Is. PEC is an iso 9001:2015, NSIC-CRISIL, Dun Bradstreet (862376458), IEC, FGI, DIC, EEPC & EXIM registered company. PEC’s Automatic Voltage Controllers/ Rectifiers have a robust design and give trouble-free service. we provide you the finest products designed and engineered by people & professionals who have experience and expertise in each sphere of activity right from testing, quality control, manufacturing & designing of these products for the last 35 years. we have with us the state-of-the-art infrastructure with excellent and advanced capabilities to manufacture world-class automatic voltage controller with quality standards. TECHNOLOGY: Voltage Regulator is the essential and main functional part of AVC equipment. our voltage regulators are liner-type regulators with rolling contact carbon rollers. we use heavy-duty carbon rollers which do not need any replacement for at least 20-25 years. COMMITMENT: we have a commitment to provide a FIVE-YEAR GUARANTEE for all the equipment supplied by us. After-sales service is the backbone of our organisation. We have developed and installed industrial Automatic Voltage Controller throughout India which are suitable for 100% continuous duty cycle supplied up to 5000 kva which have more than 99.5% efficiency. ADVANTAGES OF INSTALLING AVC : Customer will certainly have the following advantages in case they are getting higher input voltage i.e. more than 230 volts single phase/400 volts three phase. • Reduction in breakdown of electrical equipment • Energy saving 5-10 % on motor load and 15-25% on lighting load. • Reduction in mdi by 10-15%. • Improvement in power factor. • Depreciation allowance @80% as per income tax act. • Uniform quality of end products. Automatic Voltage Controller primarily consists of the following 1.Linear, Plus / Minus Type Vertical Rolling Contact Voltage Regulator In our voltage regulator, we are using heavy section of electrolytic grade rectangular copper strip instead of copper wire to minimize the losses & increase the efficiency of equipment. We are also using self lubricating carbon roller assemblies instead of ordinary carbon brushes which offer more reliability and trouble free performance of the equipment. 2.Double wound buck / boost type series transformer In our buck / boost transformer we are using crgo lamination to minimize iron losses. Coils of buck / boost transformer are wound with heavy section of multi strips electrolytic copper to minimize copper losses for getting better efficiency of the equipment. 3. Electronic Control Circuit and Meter Panel Automatic Voltage Controller consists of very

Warrenty : 5years

Cooling System : Oil Cooling

Voltage : 220V

Feature : Easy Operate

Application : Stabilization

Color : Gray

Condition : New

...more

Voltage Regulators

100,000 - 500,000 Per SET

1 Set(s) (MOQ)

We are offering voltage regulators. 1. Automatic voltage regulator 2 voltage stabilizer 3 servo voltage stabilizer 4. Automatic voltage controller. Power's automatic voltage conrollers/ rectifiers have robust design and gives trouble free service. We provide you the finest products designed and engineered by the people & professionals who have the experience and expertise in each sphere of activity right from testing, quality control, manufacturing & designing of these products for last 35 years.we have with us the state of art infrastructure with excellent and advanced capabilities to manufacture world-class automatic voltage conrollers with quality standards.

Type : Auto Voltage Regulator

Certification : CE Certified,ISI Certified

Application : Voltage Use

Condition : New

Operating Temperature : -40 +70deg C

Country of Origin : India

Current Type : AC

Puncture Voltage : 1000 KVA

Electricity Volume : 5

Brand Name : PEC

Phase : 3

...more

Variable Voltage Transformer

100,000 - 500,000 Per Piece

1 Piece(s) (MOQ)

range 0- 33,000 volts 3 - phase, up to 5000 kva PRINCIPLE OF OPERATION: The Variable Voltage Supply/ Regulator consist of following basic components depending on the rating of the equipment. 1) Step up Transformer 2) Buck boost transformer 3) Rolling contact type voltage regulator 4) Automatic control gear Variable Voltage Supply/ Regulator with constant Input and variable output. It consists of a Step up Transformer, 6 nos. Regulators and Buck Boost transformer. This circuit is normally used to Vary on load voltage when the regulator used in conjunction with buck/boost transformer and step up transformer. The equipment are available with following control devices: a) Manual version b) Motorised version c) Remote control In manual version a Hand wheel T Handle is provided and desired output voltage can be obtained by rotating the Wheel Handle manually. In case of motorized version and servo motor will be provided which can be operated by two sets of push buttons or toggle switch for raising and lowering the output voltage. In case of remote control arrangement one extra set of push buttons will be provided in your main panel from where the operator would be able to maintain the desired voltage with the help of those push buttons. DESCRIPTION ROLLING CONTACT REGULATOR This is essential a Continuously tapped auto wound transformer having helical coils mounted on a conventional laminated transformer core. However, the regulating winding is designed as a single layer type giving longer and slimmer version of the transformer coil but in principal it is the same. The regulating winding is varnished and baked to improve rigidity and ensure that the construction is non hydroscopic. After proper treatment longitudinal/track is ground on the coil to form a bared copper surface with the winding wire covering providing inter turn insulation. Graphite rollers , assembled on carrier boards, traverse throughout the length of the coil track. These rollers are connected electrically with the output terminals and as they are driven over the track a variable voltage is obtained. The Regulator may be of one sided or can be made double sided. In case of double sided Regulator both side of regulating winding is bared and allows rollers to be driven in opposite direction on either side of the coil. In such cases carrier boards are provided on both sided of the coils and the output terminals will be taken out though balancing transformer. The contact carrier is driven by a hand wheel / T–Handle or motor which is coupled to the chain drive. Limit switches operated by the carrier board are fitted to prevent over run. In case of your specific requirement additional limit switches will be fitted for minimum position inter-locking along with the auxiliary circuit. The power supply of the motor is derived from the Regulator unless otherwise specified. The entire regulator assembly is housed inside a rigid M.S.Tank filled with oil. The Hand wheel / T – Handle, Motor push buttons etc. is fixed up inside a separate sheet steel box which is attached to the main tank. Wherever automatic control is required the solid stat voltage sensing relay is also provided inside a sheet steel box fitted along with the regulator tank.

Brand Name : PEC

Material : Copper

Cooling Type : Oil Cooled

Operating Type : Semi Automatic

Usage : Industrial

Certification : ISO 9001:2008

Packaging Type : Wooden Box

Input Voltage : 440V

Output Voltage : 0-1100 V

Phase : Three Phase

Warranty : 3 Year

Country of Origin : India

Corrosion Resistance : Yes

...more

Variable Voltage Auto Transformer

100,000 - 500,000 Per Piece

1 Set (MOQ)

The variable voltage regulator makes variable voltage supplies from 0-11 kv or any desired voltage upto 5000 kva. These variable voltage supplies are used for special purpose applications and testing. principle of operation : the variable voltage supply regulator consist of following basic components depending on the rating of the equipment. Step up transformerbuck boost transformerrolling contact type voltage regulatorautomatic control gear the variable voltage regulator comes with variable voltage supply regulator with constant input and variable output. It consists of a step up transformer, regulators and buck boost transformer. This circuit is normally used to vary on load voltage when the regulator used in conjunction with buckboost transformer and step up transformer. the equipment is available with following control devices : manual version motorized version remote control in manual version a hand wheel t handle is provided and desired output voltage can be obtained by rotating the wheel handle manually.in case of motorized version and servo motor will be provided which can be operated by two sets of push buttons or toggle switch for raising and lowering the output voltage. In case of remote control arrangement, one extra set of push buttons will be provided in your main panel from where the operator would be able to maintain the desired voltage with the help of those push buttons. description : rolling contact regulator : this is essential a continuously tapped auto wound transformer having helical coils mounted on a conventional laminated transformer core. However, the regulating winding is designed as a single layer type giving longer and slimmer version of the transformer coil but in principal it is the same. the regulating winding is varnished and baked to improve rigidity and ensure that the construction is non-hydroscopic. After proper treatment longitudinaltrack is ground on the coil to form a bared copper surface with the winding wire-covering providing inter turn insulation. Graphite rollers, assembled on carrier boards, traverse throughout the length of the coil track. These rollers are connected electrically with the output terminals and as they are driven over the track, a variable voltage is obtained. the regulator may be of one sided or can be made double sided. In case of double sided regulator both side of regulating winding is bared and allows rollers to be driven in opposite direction on either side of the coil. In such cases carrier boards are provided on both sided of the coils and the output terminals will be taken out though balancing transformer. the contact carrier is driven by a hand wheel t handle or motor, which is coupled, to the chain drive. Limit switches operated by the carrier board are fitted to prevent over run. In case of your specific requirement, additional limit switches will be fitted for minimum position inter-locking along with the auxiliary circuit. The power supply of the motor is derived from the regulator unless otherwise specified. The entire regulator assembly is housed inside a rigid m.s.tank filled with oil. The hand wheel t handle, motor push buttons etc. Is fixed up inside a separate sheet steel box, which is attached to the main tank. Wherever automatic control is required, the solid stat voltage-sensing relay is also provided inside a sheet steel box fitted along with the regulator tank. for voltage regulating units, the equipment consists of regulator and transformer as explained earlier. The description of the regulator has been already described above. The step up and buck boost transformer will be of conventional type as per is:1180 or is:2026 in voltage regulating un

Type : Variable Voltage Auto Transformer

Certification : ISO 9001:2008 Certified

Color : Green

Condition : New

Output Type : AC Three Phase

Frequency : 50hz

Automatic Grade : Automatic

Cooling System : Oil Cooling

Warrenty : 2years

Country of Origin : India

Phase : 3

...more

Variable Voltage Regulator

30,000 - 100,000 Per piece

The Variable Voltage Regulator makes variable voltage supplies from 0-11 KV or any desired voltage upto 5000 kva. These variable voltage supplies are used for special purpose applications and testing. Our Variable Voltage Regulator has been designed, manufactured and tested with proper care and attention, to give efficient service. Voltage Regulator/Regulating units manufactured by us comply with IS: 1180 and IS: 2026 as far as applicable. Principle of Operation : The Variable Voltage Supply/ Regulator consist of following basic components depending on the rating of the equipment. Step up Transformer Buck boost transformer Rolling contact type voltage regulator Automatic control gear Figure shows 2000 KVA capacity Variable Voltage Supply/ Regulator with constant Input voltage of 11 kv and variable output voltage from 0-11 kv. It consists of a Step up Transformer, 2 nos. Regulators and Buck Boost transformer. This circuit is normally used to Vary on load voltage when the regulator used in conjunction with buck/boost transformer and step up transformer. The equipment are available with following control devices: Manual version Motorised version Remote control In manual version a Hand wheel / T – Handle is provided and desired output voltage can be obtained by rotating the Wheel / Handle manually. In case of motorized version and servo motor will be provided which can be operated by two sets of push buttons or toggle switch for raising and lowering the output voltage. In case of remote control arrangement one extra set of push buttons will be provided in your main panel from where the operator would be able to maintain the desired voltage with the help of those push buttons. Description-Rolling Contact Regulator This is essential a Continuously tapped auto wound transformer having helical coils mounted on a conventional laminated transformer core. However, the regulating winding is designed as a single layer type giving longer and slimmer version of the transformer coil but in principal it is the same. The regulating winding is varnished and baked to improve rigidity and ensure that the construction is non hydroscopic. After proper treatment longitudinal/track is ground on the coil to form a bared copper surface with the winding wire covering providing inter turn insulation. Graphite rollers , assembled on carrier boards, traverse throughout the length of the coil track. These rollers are connected electrically with the output terminals and as they are driven over the track a variable voltage is obtained. The Regulator may be of one sided or can be made double sided. In case of double sided Regulator both side of regulating winding is bared and allows rollers to be driven in opposite direction on either side of the coil. In such cases carrier boards are provided on both sided of the coils and the output terminals will be taken out though balancing transformer. The contact carrier is driven by a hand wheel / T–Handle or motor which is coupled to the chain drive. Limit switches operated by the carrier board are fitted to prevent over run. In case of your specific requirement additional limit switches will be fitted for minimum position inter-locking along with the auxiliary circuit. The power supply of the motor is derived from the Regulator unless otherwise specified. The entire regulator assembly is housed inside a rigid M.S. Tank filled with oil. The Hand wheel / T – Handle, Motor push buttons etc. is fixed up inside a separate sheet steel box, which is attached to the main tank. Wherever automatic control is required, the solid stat voltage-sensing relay is also provided inside a sheet steel box fitted along with the regulator tank. In VOLTAGE REGULATING UNIT the equipment consist of Regulators and Transformers are explained earlier. The description of the Regulator has already been described above. The Transformer (buck/boost and step up) are of conventional design as per IS: 1180 or IS:2026. The Regulator is combination with transformer gives the desired regulation of the voltage in case of higher capacity and H.T equipment. Some times in Low Voltage higher capacity units the regulator and the transformers are enclosed inside a single tank, however, in case of a high voltage higher capacity units the regulator is housed inside a separate tank and transformer is housed in another tank. A separate instruction and maintenance manual for the transformer is enclosed here with which will be applicable only to the transformer part of the regulating unit.

Type : Variable

Certification : CE Certified

Application : Voltage Flow

Operating Temperature : -25 +85deg C

Automatic Grade : Semi Automatic

Current Type : AC, DC

Puncture Voltage : 100-200KW

Phase : Single Phase

...more

Ultra Isolation Transformers)

100,000 - 500,000 Per piece

1 Piece(s) (MOQ)

Electrical transformers, or simply transformers are the electrical devices meant for transforming the electric energy. The basic function of a transformer is to alter the voltage, usually from high to low. In other words, a transformer solves the purpose of transiting the power from the power plants to houses, offices, markets, malls, etc., in an appropriate state. Nowadays, electrical transformers are available in several different types. Also, the size of electrical transformers vary according to the area of their application. For instance, the transformers required for power stations are multi-ton units, which are large and bulky; electrical transformers used on electric poles are intermediate units, which are medium sized; electrical appliances in homes, offices, etc., require compact transformers. electrical transformers manufactured by power engineers & consultants are precisely and efficiently engineered to render optimum value for your money. Our transformers ensure safe and economical transfer of current from the main power supply to the relevant equipment. Our range of electrical transformers is mentioned below: special purpose transformers the special purpose transformers found their application in areas where the voltage requirement of the machines available differ significantly from the standard voltage. Our special purpose transformers are at the forefront in the industry. We strictly adhere to the international quality standards while manufacturing these transformers. We also entertain custom requirements up to 5000 kva. Power distribution transformers the main function of a power distribution transformer is to transform the electrical supply from the main source into a predefined voltage, which should be appropriate for the destination equipment. We use high quality materials and advanced production techniques for manufacturing these transformers. We are also capable of custom designing these transformers according to the client's specifications. Our power distribution transformers are primarily demanded by large manufacturing units, electricity boards, and windmills. ultra isolation transformers ultra isolation transformers are considered ideal for eliminating line disturbances and preventing faulty and erratic operation of certain sensitive equipment like computer, computerized machines, medical equipment, cnc machines, digital communication telemetry systems, and so. We are quite specialized in manufacturing this particular variety of transformer. Our ultra isolation transformers are highly effective in eradicating the disturbances generated in consequence of the noisy equipment load which get injected into the power line. These transformers are also custom engineered by us to suit the specific needs of our clients.

...more

Ultra Isolation Transformer

10,000 - 900,000 Per piece

1 set (MOQ)

Ultra Isolation Transformer is manufactured by us with the aid of latest technologies to protect the Isolating sensitive equipment. We also offer power isolation transformers and super isolation transformer in the market. The Ultra Isolation Transformers are specially designed for sensitive critical equipment like computers & peripherals, medical instrumentation, digital communication telemetry systems, CNC Machines etc. and stopping such disturbances generated by the noisy equipment load from being injected into the power line. Multiple shielding techniques employed reduce the inter winding capacitance to below 0.005 Pico farad and increase D.C Isolation to over 1000 Megohms. Technically, transformers that have no direct current path between their primary & secondary windings provide Isolation. Other commonly used, transformers even if they have separate primary & secondary winding are intended to convert the input voltage to a more useful level & do very little to attenuate the passage of noise or transients from primary to secondary. Even through both are separately wound transformers, they are substantially different w.r.t construction, specification & performance characteristics. In shielded transformer, Four Low impedance path exists for noises to pass to secondary & vise versa. : The High Value of Coupling Capacitance. The Maximum Linkage of Magnetic Field. The Leakage Current. Static transformer of Electric Noises. Provides Protection Against : Line Voltage transients Spikes D.C Leakage

Type : Three Phase Isolation Transformer

Brand Name : PEC

Material : Copper

Certification : ISO 9001:2008

Weight : 5-10 Tons

Color : Sliver

Voltage : 440 V

Packaging Type : Wooden Box

Driven Type : Electric

Standard : IS 2030

Phase : Three Phase

Warranty : 3 Year

Operating Type : Manual

Usage : Industrial

...more

Three Phase Voltage Stabilizer Oil Cool

100,000 - 500,000 Per piece

1 piece (MOQ)

Servo stabilizer is an automatic voltage regulator, which primarily consists of the following features : • linear, plus / minus type vertical rolling contact voltage regulator for making these regulators, we use heavy section of electrolytic grade rectangular copper strip instead of copper wire in order to minimize the losses & increase the efficiency of equipment. We also employ self lubricating carbon roller assemblies instead of ordinary carbon brushes that offers more reliability and trouble free performance of the equipment. • double wound buck / boost type series transformer in our buck / boost transformer, we make use of crgo lamination to reduce iron losses. The coils of buck / boost transformer are wound with heavy section of multi strips electrolytic copper to minimize copper losses to get better efficiency of the equipment. • electronic control circuit and meter panel automatic voltage controller usually consists of very simple electronic control voltage circuit for monitoring and controlling voltage, repair and maintenance of which is very easy. The regulator and buck / boost transformer are oil cooled, placed in same or separate sheet steel tanks. These devices are provided with radiators for effective cooling. The coils of voltage regulators & buck / boost transformers are vacuum impregnated and oven dried as per is.

Brand Name : PEC

Material : COPPER

Color : Grey

Condition : New

Automatic Grade : Automatic

Produce Power : 630 kva

Application : industrial

Certification : CE Certified, ISO 9001:2008

Feature : Auto Cut, Easy Operate, Stable Performance, Works In Low Voltage

Output Type : AC Single Phase, AC Three Phase

Cooling System : Air Cooling, Oil Cooling

Type : oil cool

...more

Special Purpose Transformers

100,000 - 500,000 Per Piece

1 Piece(s) (MOQ)

Electrical transformers, or simply transformers are the electrical devices meant for transforming the electric energy. The basic function of a transformer is to alter the voltage, usually from high to low. In other words, a transformer solves the purpose of transiting the power from the power plants to houses, offices, markets, malls, etc., in an appropriate state. Nowadays, electrical transformers are available in several different types. Also, the size of electrical transformers vary according to the area of their application. For instance, the transformers required for power stations are multi-ton units, which are large and bulky; electrical transformers used on electric poles are intermediate units, which are medium sized; electrical appliances in homes, offices, etc., require compact transformers. Electrical transformers manufactured by Power Engineers & Consultants are precisely and efficiently engineered to render optimum value for your money. Our transformers ensure safe and economical transfer of current from the main power supply to the relevant equipment. Our range of electrical transformers is mentioned below: Special Purpose Transformers The special purpose transformers found their application in areas where the voltage requirement of the machines available differ significantly from the standard voltage. Our special purpose transformers are at the forefront in the industry. We strictly adhere to the international quality standards while manufacturing these transformers. We also entertain custom requirements up to 5000 kva. Power Distribution Transformers The main function of a power distribution transformer is to transform the electrical supply from the main source into a predefined voltage, which should be appropriate for the destination equipment. We use high quality materials and advanced production techniques for manufacturing these transformers. We are also capable of custom designing these transformers according to the client's specifications. Our power distribution transformers are primarily demanded by large manufacturing units, electricity boards, and windmills. Ultra Isolation Transformers Ultra isolation transformers are considered ideal for eliminating line disturbances and preventing faulty and erratic operation of certain sensitive equipment like computer, computerized machines, medical equipment, CNC machines, digital communication telemetry systems, and so. We are quite specialized in manufacturing this particular variety of transformer. Our ultra isolation transformers are highly effective in eradicating the disturbances generated in consequence of the noisy equipment load which get injected into the power line. These transformers are also custom engineered by us to suit the specific needs of our clients.

Packaging Type : WOODEN

...more

Special Purpose Transformer

100,000 - 500,000 Per Piece

The special purpose transformer offered by us includes ultra isolation trf, step up / step down or any other desired voltage sometimes machines used are of different voltage then the standard voltage available at site to operate the machine, special purpose trf is required. Systems of the special purpose transformer can be designed and manufactured by us according to customers� requirement up to 5000 kva.

Automatic Grade : Automatic

Power : 750-1000kw

Application : Industrial Use

Type : Special Purpose Transformer

Phase : 3

Warranty : 2years

Cooling System : Air Cooling

Country of Origin : India

...more

Servo Voltage Stabilizer 3 phase oil cooled

300,000 - 600,000 Per piece

1 piece (MOQ)

We engaged in the manufacturing of following products: Power distribution transformer up to 10 mva automatic voltage regulator servo voltage stabilizer up to 7000 kva rectifier transformer for electroplating , electrochemical, electrolysis, anodizing up to 25,000 amps. Cast resin epoxy transformer up to 5000 kva dry type transformer up to 5000 kva ultra isolation transformer up to 7000 kva variable voltage transformer regulator up to 8000 kva (0-35000 volts) Power Engineers Company is Manufacturer, Exporter & Supplier known for reliability and continuous improvement in the field of rolling contact type automatic voltage controller, automatic voltage stabilizer, electroplating, chemical process rectifiers and special purpose transformers. The systems are designed and supervised by a team of qualified engineers having more than 35 years of experience to achieve best possible quality to total customer's satisfaction. Introduction :In spite of best efforts by the State Electricity Boards, the voltage at consumer ends is never the required voltage. This is because of longer distribution lines and different loading at different time on Distribution Transformers. For example, a consumer near the Distribution station gets high Voltage but the farther most consumers may be getting low Volts.Most of the industries are working in the daytime, so loading on the transformer is more and generally, voltage is low in day time. In the night most of the units are closed and there is practical no domestic load, the voltage may be to the tune of 440-480 Volts.So, practically every industry needs system which may keep the voltage constant. To maintain the voltage stabilizers are available in the market for refrigerators, electrical machines and electronic equipments but these are of very low capacity. We have developed and installed industrial voltage stabilizer throughout India which are suitable for 100% continuous duty cycle supplied up to 5000 KVA which have more than 99. 5% efficiency.PEC have developed LINER TYPE REGULATOR WITH ROLLING CONTACT CARBON ROLLERS and installed up to 5000 KVA capacity. Which are suitable for 100% continuous duty cycle & having more than 99% efficiency. Commitment to provide an UNCONDITIONAL GURANTEE for FIVE YEARS. Industrial units achieve the under noted advantages after installing Automatic Voltage Controller. Reduction in breakdown of electrical equipments upto 60-80%. Energy saving : 5 to 10% on motor load & 15-25% on lighting load. Reduction in MDI : Definite reduction in MDI by 10-15%. Improvement in power factor : In case of high voltage only. Depreciation allowance @ 80% as per Income tax Act Uniform quality of end product. Voltage Optimisation is a term given to the systematic controlled reduction in the voltages received by an energy consumer to reduce energy use, power demand and reactive power demand. While some voltage 'optimisation' devices have a fixed voltage adjustment, others electronically regulate the voltage automatically. Voltage optimisation systems are typically installed in series with the mains electrical supply to a building, allowing all its electrical equipment to benefit from an optimised supply.Over Voltage Various technologies can be used to avoid overvoltage, but it must be done so efficiently so that energy savings resulting from using the correct voltage are not offset by energy wasted within the device used to do so. Reliability is also important, and there are potential problems inherent in running full incoming power through electro-mechanical devices such as automatic voltage controller.Under Voltage refers to voltage lower than the voltage at which equipment is designed to operate most effectively. If the design of the VO does not take into consideration voltage drop over distance to remote power users, then this may lead to premature equipment failure, failure to start up, increased temperature in the case of motor windings and loss of service.Effects On Electrical Loads :

Warrenty : 5years

Country of Origin : India

Cooling System : Oil Cooling

Phase : 3

Frequency : 50hz

Type : Servo Voltage Stabilizer

Output Type : AC Three Phase

Feature : Auto Cut, Works In Low Voltage

Certification : CE Certified, ISO 9001:2008

Produce Power : 630 KVA

Automatic Grade : Automatic

Condition : New

Color : Green

Brand Name : PEC

...more

Three Phase Servo Controlled Voltage Stabilizer

100,000 - 500,000 Per Piece

1 Piece (MOQ)

Power Engineers Company is Manufacturer, Exporter & Supplier known for reliability and continuous improvement in the field of rolling contact type automatic voltage controller, automatic voltage stabilizer, electroplating, chemical process rectifiers and special purpose transformers. The systems are designed and supervised by a team of qualified engineers having more than 35 years of experience to achieve best possible quality to total customer's satisfaction. Introduction :In spite of best efforts by the State Electricity Boards, the voltage at consumer ends is never the required voltage. This is because of longer distribution lines and different loading at different time on Distribution Transformers. For example, a consumer near the Distribution station gets high Voltage but the farther most consumers may be getting low Volts.Most of the industries are working in the daytime, so loading on the transformer is more and generally, voltage is low in day time. In the night most of the units are closed and there is practical no domestic load, the voltage may be to the tune of 440-480 Volts.So, practically every industry needs system which may keep the voltage constant. To maintain the voltage stabilizers are available in the market for refrigerators, electrical machines and electronic equipments but these are of very low capacity. We have developed and installed industrial voltage stabilizer throughout India which are suitable for 100% continuous duty cycle supplied up to 5000 KVA which have more than 99. 5% efficiency.PEC have developed LINER TYPE REGULATOR WITH ROLLING CONTACT CARBON ROLLERS and installed up to 5000 KVA capacity. Which are suitable for 100% continuous duty cycle & having more than 99% efficiency. Commitment to provide an UNCONDITIONAL GURANTEE for FIVE YEARS. Industrial units achieve the under noted advantages after installing Automatic Voltage Controller. Reduction in breakdown of electrical equipments upto 60-80%. Energy saving : 5 to 10% on motor load & 15-25% on lighting load. Reduction in MDI : Definite reduction in MDI by 10-15%. Improvement in power factor : In case of high voltage only. Depreciation allowance @ 80% as per Income tax Act Uniform quality of end product. Voltage Optimisation is a term given to the systematic controlled reduction in the voltages received by an energy consumer to reduce energy use, power demand and reactive power demand. While some voltage 'optimisation' devices have a fixed voltage adjustment, others electronically regulate the voltage automatically. Voltage optimisation systems are typically installed in series with the mains electrical supply to a building, allowing all its electrical equipment to benefit from an optimised supply.Over Voltage Various technologies can be used to avoid overvoltage, but it must be done so efficiently so that energy savings resulting from using the correct voltage are not offset by energy wasted within the device used to do so. Reliability is also important, and there are potential problems inherent in running full incoming power through electro-mechanical devices such as automatic voltage controller.Under Voltage refers to voltage lower than the voltage at which equipment is designed to operate most effectively. If the design of the VO does not take into consideration voltage drop over distance to remote power users, then this may lead to premature equipment failure, failure to start up, increased temperature in the case of motor windings and loss of service.Effects On Electrical Loads : A common misconception as far as Voltage Optimisation is concerned is to assume that a reduction in voltage will result in an increase in current and therefore constant power.

...more

Three phase Servo Automatic Voltage Controller Stabilizer

100,000 - 500,000 Per piece

1 piece (MOQ)

Power is an iso 9001:2015, dun bradstreet (862376458), iec, fgi, dic, eepc & nsic registered company. Having five manufacturing plants in all over india. We are engaged in the manufacturing of industrial transformers up to 10 mva (epoxy cast resin construction, dry type, oil cooled) low and medium voltage, industrial automatic voltage stabilizer ranging up to 7000 kva capacity (u.k. Based brentford type), variable voltage supply (0 – 33000 volts), special purpose transformers (step up / step down, auto transformers, ultra isolation transformers), rectifier equipments from 0-1500 volts and up to 25,000 amps. For industrial applications. We provide you the finest products designed and engineered by the people & professionals who have the experience and expertise in each sphere of activity right from testing, quality control, manufacturing & designing of these products for last 35 years. We have with us the state of art infrastructure with excellent and advanced capabilities to manufacture world-class equipment with quality standards. We also have a strong and reputed presence in the overseas market and have supplied more than 1500 nos. Avc/transformers in the overseas market of various countries viz. U.s.a., south africa, kenya, ghana, angola, sri lanka, nepal, abu dhabi, nigeria etc.

Warrenty : 5years

Country of Origin : India

Cooling System : Oil Cooling

Phase : 3

Frequency : 50hz

Type : Voltage Stabilizer,Differential Copper Strip Wound

Output Type : AC Three Phase

Feature : Auto Cut

Certification : CE Certified, ISO 9001:2008

Application : Stabilization

Automation Grade : Automatic

Power : 1000 KVA

Condition : New

Brand Name : PEC

Color : Gray

Voltage : 380V, 440V

...more

Rolling Contact Type Linear Servo Voltage Stabilizer

20,000 - 500,000 Per piece

Power Engineers Company is Manufacturer, Exporter & Supplier known for reliability and continuous improvement in the field of rolling contact type automatic voltage controller, automatic voltage stabilizer, electroplating, chemical process rectifiers and special purpose transformers. The systems are designed and supervised by a team of qualified engineers having more than 35 years of experience to achieve best possible quality to total customer's satisfaction. Introduction :In spite of best efforts by the State Electricity Boards, the voltage at consumer ends is never the required voltage. This is because of longer distribution lines and different loading at different time on Distribution Transformers. For example, a consumer near the Distribution station gets high Voltage but the farther most consumers may be getting low Volts.Most of the industries are working in the daytime, so loading on the transformer is more and generally, voltage is low in day time. In the night most of the units are closed and there is practical no domestic load, the voltage may be to the tune of 440-480 Volts.So, practically every industry needs system which may keep the voltage constant. To maintain the voltage stabilizers are available in the market for refrigerators, electrical machines and electronic equipments but these are of very low capacity. We have developed and installed industrial voltage stabilizer throughout India which are suitable for 100% continuous duty cycle supplied up to 5000 KVA which have more than 99. 5% efficiency.PEC have developed LINER TYPE REGULATOR WITH ROLLING CONTACT CARBON ROLLERS and installed up to 5000 KVA capacity. Which are suitable for 100% continuous duty cycle & having more than 99% efficiency. Commitment to provide an UNCONDITIONAL GURANTEE for FIVE YEARS. Industrial units achieve the under noted advantages after installing Automatic Voltage Controller. Reduction in breakdown of electrical equipments upto 60-80%. Energy saving : 5 to 10% on motor load & 15-25% on lighting load. Reduction in MDI : Definite reduction in MDI by 10-15%. Improvement in power factor : In case of high voltage only. Depreciation allowance @ 80% as per Income tax Act Uniform quality of end product. Voltage Optimisation is a term given to the systematic controlled reduction in the voltages received by an energy consumer to reduce energy use, power demand and reactive power demand. While some voltage 'optimisation' devices have a fixed voltage adjustment, others electronically regulate the voltage automatically. Voltage optimisation systems are typically installed in series with the mains electrical supply to a building, allowing all its electrical equipment to benefit from an optimised supply.Over Voltage Various technologies can be used to avoid overvoltage, but it must be done so efficiently so that energy savings resulting from using the correct voltage are not offset by energy wasted within the device used to do so. Reliability is also important, and there are potential problems inherent in running full incoming power through electro-mechanical devices such as automatic voltage controller.Under Voltage refers to voltage lower than the voltage at which equipment is designed to operate most effectively. If the design of the VO does not take into consideration voltage drop over distance to remote power users, then this may lead to premature equipment failure, failure to start up, increased temperature in the case of motor windings and loss of service.Effects On Electrical Loads : A common misconception as far as Voltage Optimisation is concerned is to assume that a reduction in voltage will result in an increase in current and therefore constant power.

Condition : New

Automatic Grade : Automatic

Certification : CE Certified

Voltage : 360-480 V

Output Type : AC Three Phase

Type : Servo Voltage Stabilizer

Frequency : 50hz,60hz

Cooling System : Oil Cooling

Warrenty : 5years

Efficiency : 99.5%

...more

Rolling Contact Servo Voltage Stabilizer Oil Cooled

100,000 - 6,000,000 Per piece

POWER is an ISO 9001:2000, DUN BRADSTREET (862376458), IEC, FGI, DIC, EEPC & NSIC registered company. Having five manufacturing plants in all over India. We are engaged in the manufacture of Industrial Transformers up to 5 MVA (Epoxy Cast Resin Construction, Dry Type, Oil Cooled) low and medium voltage, Industrial Automatic Voltage Stabilizer ranging up to 7000 KVA capacity (U.K. based Brentford type), Variable voltage supply (0 – 33000 Volts), Special Purpose Transformers (step up / step down, auto transformers, Ultra Isolation Transformers), Rectifier equipments from 0-1500 Volts and up to 25,000 Amps. for Industrial applications.Manufactured with precision all our products are superior in quality and high in functionality. We specialize in manufacturing highly durable range of products that can be used for diverse industrial application. Our exhaustive ranges of products include :

Brand Name : PEC

Color : Green

Condition : New

Automatic Grade : Automatic

Power Capacity : 630 kva

Application : industrial

Certification : CE Certified, ISO 9001:2008

Feature : Auto Cut, Easy Operate, Works In Low Voltage

Output Type : AC Three Phase

Type : Oil Cooled Voltage Stabilizer

Frequency : 50hz, 60hz

Cooling System : Oil Cooled

Country of Origin : India

Warrenty : 5years

...more

Rolling Contact Servo Voltage Stabilizer

50,000 - 200,000 Per piece

1 piece (MOQ)

POWER is an ISO 9001:2015, NSIC-CRISIL, Having five manufacturing plants in all over India. In the domestic market, we have been supplying AVC/Rectifiers / Transformers to power utilities as well as to the corporate sector clients and so far we have supplied more than 75,000 Nos. equipment’s ranging from 30 KVA up to 7000 KVA at 415 V, 11 KV, 22 KV, 33 KV and 66 KV class to the various domestic Power Utilities in the country. We also have a strong and reputed presence in the overseas market and have supplied more than 15000 Nos. AVC/Transformers in the overseas market of various countries

Input Frequency Range : 47-63

Warrenty : 5years

Operating Frequency : 50/60

Country of Origin : India

Cooling System : Oil Cooling

Phase : 3

Frequency : 50hz, 60hz

Type : Servo Voltage Stabilizer

Output Type : AC Three Phase

Operating Temperature : 25

Certification : CE Certified

Application : Industrial

Automatic Grade : Automatic

Condition : New

Color : Green

Brand Name : PEC

Correction Rate : 25 V/s

Cooling : Onan

Ambient Temperature : 48

Efficiency : 99.5%

Output Voltage : 380/400/415

Input Voltage : 340-480 V

...more

Rectifier Chrome Plating

100,000 - 500,000 Per Piece

1 Piece(s) (MOQ)

We are offering rectifier chrome plating.the output dc voltage variation is step less by means of on load motorised regulator. We use vertical rolling contact type voltage regulator, wound with heavy section of copper strip, suitable for 100% continuous duty cycle. The life of these regulators is more than 25 years and have 4 - 5 % better efficiency in comparison to conventional dimmerstat type regulators. - please note that rectifiers manufactured by us, we are using plusminus type (+ 254 volts or + 440 volts) voltage regulator in "q" connection - which means that the capacity of voltage regulator required in our rectifier winding design is 50% in star connected (+ 254 volts) model and 30% in delta connected (+440 volts) than straight type (0-440 volts) voltage regulator used by conventional design rectifier winding. - with plusminus type voltage regulator used in our rectifier design, the capacity of voltage regulator used remains the same, but the brush current of the regulator reduces and the reliability of regulator increases. This results in considerable saving in overall power losses of our rectifier equipment.

Feature : Cost Effective,High Quality

Surface Finishing : Power Coated

Brand Name : PEC

Certification : ISI Certified,ISO 9001:2008 Certified

Color : Grey

Technics : Hot Dip Galvanized

Voltage : 415

Output Type : DC

Type : Hard Chrome Plating

Material Capabilities : COPPER

Input Voltage : 340-480 v

After-Sales Service Provided : YES

...more

Power Distribution Transformer

100,000 - 600,000 Per piece

We are engaged in manufacturing Power Distribution Transformer to meet the present-day needs of effective power distribution in various establishments. We have installed facility to manufacture Oil-filled Power and Distribution Transformers up to 10 MVA, 66 KV Class. The tested range of Power Distribution Transformers can also be customized to meet the requirements of individual, Industrial, commercial, co-generation and utility services. The Power Distribution Transformers can be provided with a variety of terminations to meet individual requirements for new installation, replacement etc. Applications : Industrial Purpose Electricity Board Domestic and Consumer Transformers Wind Mill Power transmission Standard Fitting : Monogram plate. Rating & diagram plate . Earthing terminals – 2 Nos. Lifting lugs for complete transformer. Thermometer pocket. Air release hole with plug. Oil filling hole with plug on conservator. Oil conservator with drain plug. Dehydrating breather (1 No.) sillicagel type with oil seal & connecting pipe. Prismatic oil level indicator – 1 No. Drain valve with plug – 1 No. Drain cum bottom filter valve with plug. Inspection cover. Externally operated off circuit tap changing switch. Jacking lugs. Under base with flat bi-directional treaded rollers. Radiators. Pressure relief valve without electrical contacts. Filter valve with plug. Sampling valve. LV additional neutral- out door bushing – 1 No. H.V.TERMINALS – BARE BUSHING. L.V.TERMINALS - CABLE BOX. Buchholz relay. Magnetic oil level gauge with low oil level alarm contacts Oil temperature indicator with electrical contacts for alarm and trip . Winding temperature indicator with electrical contacts for alarm and trip. Marshaling box.

Brand Name : PEC

Certification : ISO 9001:2008

Weight : 5-10 Tons

Warranty : 1 Year

Cooling Type : Oil Cooled,ONAF

Country of Origin : India

Number of Phase : Three Phase

Winding Material : Copper

Usage : Industrial

...more

Plating Rectifier

100,000 - 500,000 Per Piece

1 Piece(s) (MOQ)

The output DC voltage variation is step less by means of ON LOAD motorised regulator. We use vertical ROLLING CONTACT TYPE voltage regulator, wound with heavy section of copper strip, suitable for 100% continuous duty cycle. The life of these regulators is more than 25 years and have 4 - 5 % better efficiency in comparison to conventional dimmerstat type regulators. - Please note that Rectifiers manufactured by us, we are using plus/minus type (+ 254 Volts OR + 440 Volts) Voltage regulator in "Q" connection - which means that the capacity of voltage regulator required in our Rectifier winding design is 50% in Star connected (+ 254 Volts) model and 30% in Delta connected (+440 Volts) than straight type (0-440 Volts) voltage regulator used by conventional design rectifier winding. - With Plus/Minus type voltage regulator used in our rectifier design, the capacity of Voltage Regulator used remains the same, but the brush current of the Regulator reduces and the reliability of regulator increases. This results in considerable saving in overall power losses of our Rectifier equipment.

Brand Name : PEC

Material : COPPER

Application : ELECTROPLATING

Brand : PEC

...more

Oil Cooled Transformer

100,000 - 500,000 Per Piece

We manufacture, supply and export distribution transformer, which is deigned as per international standards. The qualitative make of the distribution transformer translates into dependable performance and an assurance of exceptional durability.

Finishing : Polished

Driven Type : Electric

...more

Oil Cooled Servo Voltage Stabilizer KVA

10,000 - 4,000,000 Per piece

1 piece (MOQ)

Power Engineers Company is Manufacturer, Exporter & Supplier known for reliability and continuous improvement in the field of rolling contact type automatic voltage controller, automatic voltage stabilizer, electroplating, chemical process rectifiers and special purpose transformers. The systems are designed and supervised by a team of qualified engineers having more than 35 years of experience to achieve best possible quality to total customer's satisfaction. Introduction :In spite of best efforts by the State Electricity Boards, the voltage at consumer ends is never the required voltage. This is because of longer distribution lines and different loading at different time on Distribution Transformers. For example, a consumer near the Distribution station gets high Voltage but the farther most consumers may be getting low Volts.Most of the industries are working in the daytime, so loading on the transformer is more and generally, voltage is low in day time. In the night most of the units are closed and there is practical no domestic load, the voltage may be to the tune of 440-480 Volts.So, practically every industry needs system which may keep the voltage constant. To maintain the voltage stabilizers are available in the market for refrigerators, electrical machines and electronic equipments but these are of very low capacity. We have developed and installed industrial voltage stabilizer throughout India which are suitable for 100% continuous duty cycle supplied up to 5000 KVA which have more than 99. 5% efficiency.PEC have developed LINER TYPE REGULATOR WITH ROLLING CONTACT CARBON ROLLERS and installed up to 5000 KVA capacity. Which are suitable for 100% continuous duty cycle & having more than 99% efficiency. Commitment to provide an UNCONDITIONAL GURANTEE for FIVE YEARS. Industrial units achieve the under noted advantages after installing Automatic Voltage Controller. Reduction in breakdown of electrical equipments upto 60-80%. Energy saving : 5 to 10% on motor load & 15-25% on lighting load. Reduction in MDI : Definite reduction in MDI by 10-15%. Improvement in power factor : In case of high voltage only. Depreciation allowance @ 80% as per Income tax Act Uniform quality of end product. Voltage Optimisation is a term given to the systematic controlled reduction in the voltages received by an energy consumer to reduce energy use, power demand and reactive power demand. While some voltage 'optimisation' devices have a fixed voltage adjustment, others electronically regulate the voltage automatically. Voltage optimisation systems are typically installed in series with the mains electrical supply to a building, allowing all its electrical equipment to benefit from an optimised supply.Over Voltage Various technologies can be used to avoid overvoltage, but it must be done so efficiently so that energy savings resulting from using the correct voltage are not offset by energy wasted within the device used to do so. Reliability is also important, and there are potential problems inherent in running full incoming power through electro-mechanical devices such as automatic voltage controller.Under Voltage refers to voltage lower than the voltage at which equipment is designed to operate most effectively. If the design of the VO does not take into consideration voltage drop over distance to remote power users, then this may lead to premature equipment failure, failure to start up, increased temperature in the case of motor windings and loss of service.Effects On Electrical Loads : A common misconception as far as Voltage Optimisation is concerned is to assume that a reduction in voltage will result in an increase in current and therefore constant power. Whilst this is true for certain fixed-power loads, most sites have a diversity of loads that will benefit to a greater or lesser extent with energy savings aggregating across a site as a whole. The benefit to typical equipment at three phase sites is discussed below.Energy Savings :

Warrenty : 5years

Country of Origin : India

Cooling System : Oil Cooling

Phase : 3

Frequency : 50hz, 60hz

Type : Servo Voltage Stabilizer

Output Type : AC Three Phase

Voltage : 380V, 440V, 360-480 V

Feature : Auto Cut, Easy Operate

Certification : CE Certified, ISO 9001:2008

Application : Industrial

Produce Power : 500 Kva

Automatic Grade : Automatic

Condition : New

Material : COPPER

Brand Name : PEC

...more

Isolation Transformer

200,000 - 250,000 Per piece

1 Set (MOQ)

Ultra Isolation Transformer is manufactured by us with the aid of latest technologies to protect the Isolating sensitive equipment. We also offer power isolation transformers and super isolation transformer in the market. The Ultra Isolation Transformers are specially designed for sensitive critical equipment like computers & peripherals, medical instrumentation, digital communication telemetry systems, CNC Machines etc. and stopping such disturbances generated by the noisy equipment load from being injected into the power line. Multiple shielding techniques employed reduce the inter winding capacitance to below 0.005 Pico farad and increase D.C Isolation to over 1000 Megohms. Technically, transformers that have no direct current path between their primary & secondary windings provide Isolation. Other commonly used, transformers even if they have separate primary & secondary winding are intended to convert the input voltage to a more useful level & do very little to attenuate the passage of noise or transients from primary to secondary. Even through both are separately wound transformers, they are substantially different w.r.t construction, specification & performance characteristics. In shielded transformer, Four Low impedance path exists for noises to pass to secondary & vise versa. : The High Value of Coupling Capacitance. The Maximum Linkage of Magnetic Field. The Leakage Current. Static transformer of Electric Noises. Provides Protection Against : Line Voltage transients Spikes D.C Leakage

Corrosion Resistance : Yes

Country of Origin : India

Warranty : 2 Year

Phase : Three Phase

Output Voltage : 380/400/415

Input Voltage : 415

Type : Three Phase Isolation Transformer

Packaging Type : Wooden Box

Voltage : 380 V

Certification : CE Certified

Usage : Outdoor,Industrial,Commercial

Speciality : High Efficiency

Operating Type : Automatic

Cooling Type : Air Cooled

Driven Type : Electric

Finishing : Polished

Material : Copper

Brand Name : PEC

...more

industrial servo voltage stabilizer

200,000 - 1,200,000 Per Piece

1 Piece (MOQ)

Automatic Voltage Regulator Power Engineers Company is Manufacturer, Exporter & Supplier known for reliability and continuous improvement in the field of rolling contact type automatic voltage controller, automatic voltage stabilizer, electroplating, chemical process rectifiers and special purpose transformers. The systems are designed and supervised by a team of qualified engineers having more than 35 years of experience to achieve best possible quality to total customer's satisfaction. Introduction :In spite of best efforts by the State Electricity Boards, the voltage at consumer ends is never the required voltage. This is because of longer distribution lines and different loading at different time on Distribution Transformers. For example, a consumer near the Distribution station gets high Voltage but the farther most consumers may be getting low Volts.Most of the industries are working in the daytime, so loading on the transformer is more and generally, voltage is low in day time. In the night most of the units are closed and there is practical no domestic load, the voltage may be to the tune of 440-480 Volts.So, practically every industry needs system which may keep the voltage constant. To maintain the voltage stabilizers are available in the market for refrigerators, electrical machines and electronic equipments but these are of very low capacity. We have developed and installed industrial voltage stabilizer throughout India which are suitable for 100% continuous duty cycle supplied up to 5000 KVA which have more than 99. 5% efficiency.PEC have developed LINER TYPE REGULATOR WITH ROLLING CONTACT CARBON ROLLERS and installed up to 5000 KVA capacity. Which are suitable for 100% continuous duty cycle & having more than 99% efficiency. Commitment to provide an UNCONDITIONAL GURANTEE for FIVE YEARS. Industrial units achieve the under noted advantages after installing Automatic Voltage Controller. Reduction in breakdown of electrical equipments upto 60-80%. Energy saving : 5 to 10% on motor load & 15-25% on lighting load. Reduction in MDI : Definite reduction in MDI by 10-15%. Improvement in power factor : In case of high voltage only. Depreciation allowance @ 80% as per Income tax Act Uniform quality of end product. Voltage Optimisation is a term given to the systematic controlled reduction in the voltages received by an energy consumer to reduce energy use, power demand and reactive power demand. While some voltage 'optimisation' devices have a fixed voltage adjustment, others electronically regulate the voltage automatically. Voltage optimisation systems are typically installed in series with the mains electrical supply to a building, allowing all its electrical equipment to benefit from an optimised supply.Over Voltage Various technologies can be used to avoid overvoltage, but it must be done so efficiently so that energy savings resulting from using the correct voltage are not offset by energy wasted within the device used to do so. Reliability is also important, and there are potential problems inherent in running full incoming power through electro-mechanical devices such as automatic voltage controller.Under Voltage refers to voltage lower than the voltage at which equipment is designed to operate most effectively. If the design of the VO does not take into consideration voltage drop over distance to remote power users, then this may lead to premature equipment failure, failure to start up, increased temperature in the case of motor windings and loss of service.Effects On Electrical Loads : A common misconception as far as Voltage Optimisation is concerned is to assume tha

Country of Origin : India

Phase : 3

Voltage : 360-480 V

Usage/Application : INDUSTRIAL

...more

electro plating rectifiers

100,000 - 500,000 Per Set

The output DC voltage variation is step less by means of ON LOAD motorised regulator. We use vertical ROLLING CONTACT TYPE voltage regulator, wound with heavy section of copper strip, suitable for 100% continuous duty cycle. The life of these regulators is more than 25 years and have 4 - 5 % better efficiency in comparison to conventional dimmerstat type regulators. - Please note that Rectifiers manufactured by us, we are using plusminus type (+ 254 Volts OR + 440 Volts) Voltage regulator in "Q" connection - which means that the capacity of voltage regulator required in our Rectifier winding design is 50% in Star connected (+ 254 Volts) model and 30% in Delta connected (+440 Volts) than straight type (0-440 Volts) voltage regulator used by conventional design rectifier winding. - With PlusMinus type voltage regulator used in our rectifier design, the capacity of Voltage Regulator used remains the same, but the brush current of the Regulator reduces and the reliability of regulator increases. This results in considerable saving in overall power losses of our Rectifier equipment.

Material : Nickel

Condition : New

Type : Electroless Plating

...moreOpening Hours