thermoset moulding

Thermoset moulding of thermoset materials is the most automatic method of processing these materials and has become the most common. The main difference between thermoset and transfer molding is reduced material handling. With Thermoset moulding, the material is fed directly into the hopper of the molding press, eliminating preforming, preform storage, and preheating. An Thermoset moulding press consists of two major sections, which are the clamping section and the material processing section. An Thermoset moulding press consists of two major sections, which are the clamping section and the material processing section. The clamping section, which is similar to a compression press, is basically a hydraulic cylinder that closes the mold halves and holds them together under pressure. In the case of a toggle press, there is a cylinder and linkage mechanism that closes the mold halves and holds them together under pressure. In addition to the clamping mechanism, this part of the press also provides the mechanism for removing the parts from the mold. What are the advantages of Thermoset Moulding? Material handling is reduced because the press hopper will usually hold sufficient material to mold parts for an extended period of time. Longer and smaller diameter core pins may be used because they can be supported on both ends. With the mold being closed before any material is injected into it, parts containing metal inserts can be molded without having material flash the inserts. Relatively tighter tolerances across parting lines are possible. Parting line flash can be held to a minimal thickness if the mold is designed properly and well maintained. Thermoset moulding of thermoset materials lends itse lf to automating the process which can result in lower piece costs.

...more

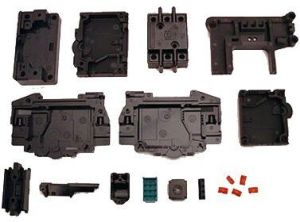

compression moulding

Compression moulding is a method of molding in which the molding material, generally preheated, is first placed in an open, heated mold cavity. The mold is closed with a top force or plug member, pressure is applied to force the material into contact with all mold areas, while heat and pressure are maintained until the molding material has cured. The process employs thermosetting resins in a partially cured stage, either in the form of granules putty-like masses, or preforms. Compression moulding is a high-volume, high-pressure method suitable for molding complex, high-strength fiberglass reinforcements.

...more

bakelite

We are a prominent Bakelite Products Manufacturer, Exporter, and Supplier in Gujarat, India. The wide range of Bakelite Products, offered by Ravi Enterprises, chiefly includes Bakelite Handles, Bakelite Knobs etc. Bakelite Products are very durable & longlasting. Moreover, these are designed in a manner so that they can be totally comfortable to hold and also look beautiful. The Bakelite Products, provided by us, have high mechanical strength, conductive & heat resistant properties, and excellent molding ability. Ravi Enterprises is engaged in offering an extensive array of Bakelite Products.

...moreBe first to Rate

Rate ThisOpening Hours