Triple Wall Glass Jacketed Reactor

Get Price Quote

Ablaze is presenting Flexi (Detachable) Transparent Double Jacketed Vessel to maintain the leading position in industry by way of developing indigenously newer products with higher value towards their Mission and to cater the customer via innovation. Salient Features of Jacketed Vessel Vacuum Jacket ensures Transparent insulation. Minimum heat loss. Process visibility. Minimize frost formation for cryogenics operation. Vacuum Jacket & main vessels are detachable ensures Ease of cleaning. No breakages due to thermal expansion. Partial Replacement of any part can be possible reduce the maintenance cost.

Limpet Coil Reactor

Get Price Quote

1 Piece (MOQ)

Best Deals from Reaction Vessels

Glass Spherical Vessel

Get Price Quote

Glass Spherical Vessels for Acidic and other corrosive fluids are made from borosilicate 3.3 glass piping conforming to EN ISO 3583 , ENBS 1595 , AD2000 Merkblatt N4 The joints are with a flat buttress for enabling a high tightening force ensuring a leak-proof joint. Capacities right from 2L to 300L are manufactured.

cryogenic vessels

260,000 - 9,800,000 Per Piece

1 Piece (MOQ)

Cryogenic vessels to store liquide nitrogen , oxygen , argon , lng , LIN, LIX , LAR ETC

Addition Spherical Vessel

Get Price Quote

Limpet Coil Reactor

Get Price Quote

SS Mixing Vessel

Get Price Quote

Cylindrical Glass Vessel

Get Price Quote

We manufacture & Supply Al type of BoroSilicate Glass Vessel

glass reactor

Get Price Quote

We are offering glass reactor.

Wire Mesh Structured packing

Get Price Quote

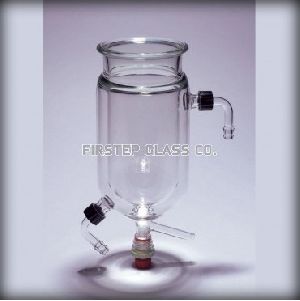

Borosilicate Glass Jacketed Vessel

Get Price Quote

50 Piece(s) (MOQ)

we offer Borosilicate Glass Jacketed Vessel. For special applications, cylindrical vessel can be supplied with a jacket-for heating or cooling.Jacket is sealed to the vessel with silicon rubber or viton ring and other sealing compositions.The seal prevents impermissible high stresses between vessel and jacket and allows the movement which comes due to thermal expansion. Glass jacket can be used for a maximum operating pressure of 0.5 bar g. Maximum operating temperature of 150°C in jacket. Temperature difference between jacket & vessel should not be exceed 120°C.

Mobile Mixing Vessels

91,000 - 251,000 Per Piece

1 Set (MOQ)

UD offers trolley mounted mixing vessels from 5 liter to 500 liter. The vessels are supplied with graduations. The bottom drain valve can be simple straight through valve or flush bottom type for least hold up of liquid. Jacketed mixing vessels can be supplied up to 50-liter capacity. The agitator is of Mild steel lined with PTFE lining and PTFE blades. Pitch blade agitator is standard supply. The agitator is supplied as single stage or multistage depending upon the total length of the shaft and the agitation requirement. Supporting framework Supporting framework is of 25 NB Stainless steel pipes and connectors Mild steel powder coated trolley for movement

Rubber Lined Reactor

45,000 Per Piece

1 Piece(s) (MOQ)

Mobile Mixing Vessels

Get Price Quote

We are an affluent Manufacturers, Exporters and Suppliers of Mobile Mixing Vessels in Gujarat, India. Our Mixing Vessels are easy to move from one place to another. We can provide Mixing Vessels that are quality tested and known for their durability. We can provide Mobile Mixing Vessels in variety of sizes and models so as to meet the different needs of buyers. Our Mixing Vessels are very reasonably priced. Description : Super offers trolley mounted mixing vessels from 5 liter to 500 liter. The vessels are supplied with graduations. The bottom drain valve can be simple straight through valve or flush bottom type for least hold up of liquid. Jacketed mixing vessels can be supplied up to 50-liter capacity. The agitator is of Mild steel lined with PTFE lining and PTFE blades. Pitch blade agitator is standard supply. The agitator is supplied as single stage or multistage depending upon the total length of the shaft and the agitation requirement. Technical Specification : Separator vessel - Borosilicate glass Drain valve for heavy phase - Borosilicate glass straight through OR Flush bottom valve Agitator - Mild steel PTFE lined pitch blade type Drive - 0.37 kw, 1440 rpm, flame proof induction motor, helical gear drive, Speed Control - Variable frequency drive Control Panel - Flame proof enclosure for VFD with ON-OFF push buttons Sealing - Single PTFE Bellow type dry running mechanical seal Supporting structure - Stainless Steel pipes and components with Supporting frame work - Supporting frame work is of 25 NB Stainless steel pipes and connectors. Mild steel powder coated trolley for movement

Pressure Vessels

Get Price Quote

Pressure vessel in Chemical Engineering A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. The term pressure vessel refers to vessels operating above the atmospheric pressure, or subject to external pressure.

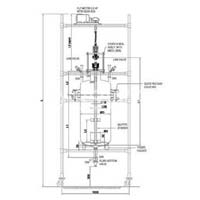

Pressure Vessel & Reaction Vessel

100,000 - 5,000,000 Per piece

1 Piece (MOQ)

We involve in providing a qualitative range of Pressure Vessels and Reaction Vessels that are used in various industries.These are utilized for processing of liquids, gases or vapour at different levels of Temperatures & pressures in varied Industries.As per Design Data & Detail Engineering Drawing, we manufacture by Carbon Steel, Alloy Steel & Stainless-Steel material. MATERIAL : Carbon Steel, Alloy Steel & Stainless Steel etc.SIZE : Max. Weight 10 Tons.SERVICE OFFERED : Engineering Solution, Design calculation, Detail Engineering, Raw material Procurement, Fabrication work, Testing Performed as per QAP, Documentation

Air Pressure Vessel

Get Price Quote

Equipped with the most up-to-date inventory control and management system, we cater to the seasonal demand to a continuous one as well. We keep records of the products to make sure that the range is kept safe in our spacious warehouse. Customers are free to place small as well as bulk orders, timely deliveries of the same are our topmost priority.

Pressure Vessel

Get Price Quote

We provide a wide range of Pressure Vessels for our clients based not only in India but also in UK. Pressure Vessels are manufactured from 300 grade stainless steel, SA 516 GR 70 and carbon steel. Pressure Vessels are quality tested on well-defined parameters before being delivered to our clients. Pressure Vessels are used in chemical, fertilizers, food and dairy, petrochemical, pharmaceutical, chemical, pulp and paper sectors. Specifications Design Codes : ASME sec VIII Div I, IS: 2825, or custom design Pressure Testing : Up to 30 bars

Pressure Vessel

Get Price Quote

Pressure Vessels We are engaged in designing detailing as per ASME SEC.VIII-DEV.1 manufacturing and supplying an extensive range of Pressure Vessels such as air receivers. These air receiver tanks are developed for full vacuum service or air storage. The standard material used to manufacture them in normally carbon steel. But on client's demands we also offer stainless steel made air receiver tanks. These tanks are also used for trains, trucks, ships and different types mobile equipment. Mentioned below are the specifications of this product: • Available in 456 standard sizes. • Diameters ranging from 10" to 120" • Pressures up to 1000 psi • Conformed under ASME, CE and CM certifications • Useful for custom OEM, industrial and process applications

FRP Radome

1,000 - 17,000 Per Piece

1000 Piece(s) (MOQ)

Pressure Vessels

Get Price Quote

We design Pressure Vessels per ASME Sec VIII Div-1 & 2, PD 5500, EN13445, AD 2000 and IS: 2589 codes. We and our associates can manufacture pressure vessels, columns, receivers, rotary reaction vessels, blending and dispersion vessels and storage tanks and all combinations of TEMA exchangers plus hair pin, pipe in pipe, tank coils, suction heaters, air fin coolers within code bounded practices. The cost effectiveness and timely delivery are our targets. We can execute jobs under Third-party inspection. We do supply all relevant documents along with the equipment and Operation & maintenance manual, preventive maintenance charts are facilitated for right operation and maintenance.

Chemical Reactors

Get Price Quote

With immense experience of the domain, we are manufacturing and supplying a wide array of excellent quality range of Chemical Reactors. These products are highly demanded in the market for their affordable prices, optimum durability, fine finish and long service life. These products are available at various specification and capacities to fulfill the various requirements of the valuable clients.

Vessels

Get Price Quote

All pressure vessels, tanks, reactors, fermentors, mixing vessels, multi agitator vessels, in all materials of construction includes c.s with all linings, all grades of ss, duplex steel, aluminium, copper, monel, inconel , haste alloy etc. pressure from atmospheric to 300 kgcm2, sizes from 500 lit to 500 kl. workshop fabricated or site fabricated under any 3rd party inspection, under ccoe classification, static or mobile, normal or heated or cryogenic vessels reactors

Glass Jacketed Vessel

15,000 - 300,000 Per Piece

10 Piece(s) (MOQ)

Reaction Vessels

Get Price Quote

We are offering reaction vessels.

Pressure Vessel

Get Price Quote

Shree Bhavani Fabricators is a well-known Manufacturer and Supplier of Pressure Vessels. Our range of Pressure Vessels is fabricated using good quality raw materials sourced from trusted vendors. The Pressure Vessel is a closed shaped container, which is designed to hold liquid or gases at a pressure different from ambient pressure. The range can also be customized as per the specifications given by the clients.

Stainless Steel Reaction Vessel

Get Price Quote

To satisfy the unique needs of our clients, we specialize in the design and production of Reaction Vessels. High-quality materials, like stainless steel and mild steel, are used in the construction of our vessels to ensure their dependability and longevity. Depending on the needs of the customer or using our standard design, we offer vessels with a range of capacities. For effective operation, our vessels are outfitted with a reduction gearbox and electric motor. Depending on the application and process requirements, the stirrer is available in the Anchor, Turbine, or Impeller types. We also produce Conical Vessels, Evaporating Pans, and other specialized Storage Tanks in addition to Reaction Vessels. Our products are created and produced in accordance with the highest quality standards, guaranteeing dependable performance and trouble-free operation. We take great satisfaction in providing our clients with top-notch service and support, from design and manufacture to installation and commissioning. Get in touch with us to talk about your needs and see how we can offer you a solution that is tailored to fit them.

Chemical Reactor

Get Price Quote

Laboratory Glass Vessel

200 Per Piece

Laboratory Glass Vessel

Get Price Quote

Plastic Granules, Parrot Green Masterbatch, Plastic Bags, Plastic Filler