poultry drinking system

Immediately after liquidating flocks, spray entire poultry house (inside and outside) with an approved insecticide in accordance with the manufacturer’s direction. This should be done prior to removal of litter and equipment. Allow sufficient time for insecticide to work. Remove all litter and dust. Then wash the house and equipment thoroughly with a pressurized water jet. Ensure that maximum possible organic matter and dirt is removed from inside and outside of the house. Make sure that all wire nets, iron structures, concrete structure and roof are thoroughly cleaned. When the building has completely dried, use selected disinfectants like quaternary ammonium compound, idophores, liquid ammonia or other commercially available approved disinfectants. One can also treat floors and parapet walls with caustic soda. Follow expert’s advice regarding dosages, procedures and compatibility. Place all disinfected equipments in place.

...more

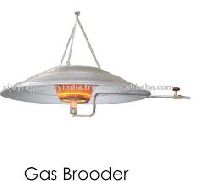

Gas Brooder

Use of LPG operated Gas Brooders gives much more uniform heat as compared to conventional types of brooding practices like Electric Lamps, Coal or Wood. The radiant Gas Brooder creates microclimate for the chicks so that they can choose their most comfortable place and warmth at any time. This results in proper growth and weight gain, which is more uniform. LPG Gas Brooding can be done either by central Control System or by Individually Controlled Infra Red radiant gas brooders. You should remember that any brooding system must have temperature control device. The advantage of this temperature control are to meet the precise heat requirement of the birds which changes with their age and energy saving. Infra Red Radiant Brooder can be placed 90 to 130 cm above the ground level depending upon the heat requirement. The number and types of Gas Brooders can be decided as per the specifications of the Gas Brooder. It is very important to note that the Gas Brooder, which you select, spells out the specifications in terms of BTUKW rating, operating pressures, etc. It is always safe to select the brooder, which has got international quality mark for safety and reliability. Before chicks arrive, please ensure that the filled LPG Gas Cylinders are available at the site. Maintain temperature of 32 to 34° C on day one. Measure the same at 10 to 25 cm above the litter level. Lower the temperature approximately by 3° C per week until attaining a temperature of 25° C. The temperature can be sensed by a sensor connected to the individual Gas Brooders or the Central Control System.

...moreBe first to Rate

Rate This