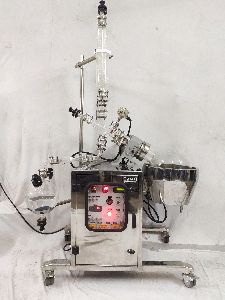

Rotary Film Evaporator

Get Price Quote

Our Rotary Film Evaporator is available with CE Marking as per PED - 97/23/EC, The Machine Directive - 98/37/EC, The European Low Voltage Directive - 73/23/EEC, The EMC Directive - 89/336/EEC. We have carved a niche as one of the overruling Rotary Evaporator Manufacturers based in India. In addition to this, we are also counted among the major Rotary Vaccum Film Evaporators Suppliers. The Rotary Film Evaporator is essentially a Thin Film Evaporator incorporating a rotating evaporation flask. The rotary evaporator will evaporate solvent at a much faster rate than systems using stationary evaporation flasks, due to higher convectional heat transfer coefficient. The rotation transfers a thin film of the liquid to the whole of the inner surface of the flask, markedly increasing evaporation rate due to higher heat transfer between the flask, bath and the thin film. The rotating flask and vapour duct have a sealing system, which allows operation under vacuum, further accelerating the evaporation process because of the reduction in boiling point of the solvent and efficient removal of the vapour. Besides the reduction in boiling point, there is a considerable decrease in the residence time of the fluid, which also permits heat sensitive materials to be successfully concentrated without degradation. The evaporators can be evacuated down to less than 1 mbar if the vacuum seals are maintained in good condition. A continuous feed facility considerably increases the capacity of the units and distillate withdrawal facilities on some units allow uninterrupted operation. Features Digital display & auto control of rotation speed, vapor temperature and bath temperature. Miniature circuit breaker and separate power switches for control panel and heating bath offers safety. Vacuum Controller (Optional) RS-232 / 485 interface (Optional) The units can be offered with full automation incorporating a PLC based system or even SCADA for real time data acquisition and control. There is a range of models covering an evaporation flask capacity from 1 litre 5 litres. The majority of these models may be used on the laboratory bench; the larger models (10, 20, 50, 100 litres and above) are designed for use in pilot plants and production facilities.

Rotary Film Evaporator

Get Price Quote

Ablaze is a leading Rotary Evaporator Manufacturer and Supplier, we offer a large capacity commercial rotary vaccum evaporator. The Ablaze Rotary Evaporator system operates under conditions of vacuum or atmosphere. The most common form in research is the 1 Liter to 5 Liter bench-top model, whereas, in industrial chemical operations, large-scale rotary evaporator (10L to 20 Liter and 50 Liter, 100 Liter to 200 Liter) models are used in pilot plants. Ablaze’s series of Rotary film Evaporators are designed for Pilot and industrial scale evaporation applications. Exclusive use of superior quality Borosilicate 3.3 glass and PTFE for all components coming in contact with product ensures complete chemical resistance against almost all mediums. It is primarily used for distillation of heat sensitive and volatile components, owing to its unique construction. It can operate under full vacuum and is an essential equipment in the chemical and pharmaceutical industries. Salient Features of Rotary Evaporator : Universal heating bath up to 200ºC High Quality (Reinforced PTFE) seal ensures perfect vacuum & maintenance free operation Digital display/control of critical process parameters on a control panel Uniform heating and reduced residence time Mounted on caster wheels for easy movement Visibility of the entire process Rotary Evaporator Manufacturer & Supplier The rotary evaporator (rotavaps) is an instrument for an active and mild extraction of solvents by evaporation in chemical, pharmaceutical, cosmetics, herbal extraction and fragrances, and laboratories. Rotary vaccum evaporators are also used for the chemical processing of distillates and extracts. The use of borosilicate and PTFE allows aggressive materials to be handled satisfies all application needs. Explore the wide variety of industrial and R&D rotary evaporators. Completely safe instruments and the best optimization of efficiency. Ablaze manufacture and supply a variety of rotary film evaporator capacities of 5 liters, 10 liters, 20 liters, 50 liters, 100 liters, 200 liters, GMP Model & Non-GMP Model, including electrical ATEX/Non-flame proof/touch screen display or as needed by the customer. Rotary Evaporator Working Concept The most rapid, reliable and environmentally safe method of extracting a volatile solvent from a non-volatile sample is to provide a rotary evaporator. For a modern chemical laboratory, this is normal equipment used to evaporate the solvent under vacuum with the use of rotation and heat. The theory of the rotary evaporator is that the boiling points of the liquids decrease their pressure, allowing solvents to be vaporized at much lower temperatures at normal pressure than their boiling points. A vacuum system is required to complete the entire procedure, selecting an appropriate vacuum pump for your rotavap will effectively improve the efficiency of the evaporation. At the other end, a condenser converts gas into a liquid, and lower temperatures are required. Dry ice, water or liquid nitrogen were always used to achieve a cooling effect. The evaporation vessel rotates continuously. This technique is intended to increase the fluid surface area. The centrifugal force prevents the liquid from sticking to the vessel’s inner surface, creating a larger surface area and causing faster evaporation. Once all the solvent evaporated (or whatever is desired at this point), the vacuum is released. The rotary flask is removed from the bath and the rotation is stopped. The vacuum is used to lower the boiling temperature thus minimizing the damage to the thermolabile substance. Rotary Evaporator Applications : Distillation under continuous and batch Organic chemistry to remove a solvent Organic synthesis Solvent recycling Solvent purification Reflux process reactions Component drying Fine chemical synthesis Crystallization Why Buy Rotary Evaporator from Ablaze? Related Rotary Evaporator Glassware can be customized to meet the specific needs of the Client. Get the best rotary film evaporator performance at a reasonable cost. We also have a professional technology team to help clients with problems related to their system (rotary evaporator). Our technical experts are always available, by phone, e-mail or live chat, to help customers with specific questions about the operation and maintenance of rotary evaporators.

Best Deals from Rotary Evaporators

Automated Rotary Film Evaporators

Get Price Quote

10 pieces (MOQ)

20 Liter Rotary Film Evaporator

390,000 - 551,000 Per Set

1 Set(s) (MOQ)

Jumbo Rotary Film Evaporator

Get Price Quote

Rotary Film Evaporator is a very regular usage product in the R & D of chemical & Pharmaceutical industry. It is also being used nowadays for manufacturing purpose for high value pharmaceutical & specialty chemical products. The existing rotary film evaporators, which are used are with spherical evaporating flasks. What happens is when the requirement of volume for process it is practically very difficult to handle the size beyond 50 liters. Chemical reactors are cylindrical in shape with a perticular LD ratio in general, which are given for a particular reaction surface area. The cylindrical vessel has a higher surface area spherical vessel. This prompted us to think in the direction; why only spherical vessel is used when we can exploit the advantage of cylindrical shape evaporation flask in a rotary film evaporator.

Rotary Evaporator

Get Price Quote

We are a prominent Manufacturer, Exporter and Supplier of Rotary Evaporator in Gujarat, India. Our Evaporator is fabricated as per the international quality standards ensuring the best quality. The Evaporator that we offer has wide laboratory applications. We can provide Evaporator with varied technical specifications as per the requirements of different buyers. Our Rotary Evaporator is available at the best prices in the market. Description : The SUPER ROTA 50&100 rotary evaporator is simple to operate, with standard glass components and useful in a variety of laboratory applications. This could used at production facilities also. It is also available with control panel and electrical drives suitable for operation in explosion proof zones as optional. Available with simple control panel with clear vision and self-explanatory functions. LED displays for bath temperature, vapour temperature and RPM are standard features. Manometer for vacuum Measurement as part of supply. It can be offered with different condenser configurations like downward condenser, double condensers, short condenser etc. Motorized bath lift is standard supply. Speed control from 5 to 60 RPM with AC drive. Flask drive interlocked with bath lift Flask support supplied for easy fixing and removal of rotating flask Trolley mounted system permits easy movement from anywhere

Industrial Rotary Evaporator

295,000 - 450,000 Per piece

1 Piece (MOQ)

Mild Steel Rotary Evaporator

Get Price Quote

Rotary Evaporator

150,000 - 900,000 Per Piece

1 Piece(s) (MOQ)

Rotary Evaporator

Get Price Quote

5 Set(s) (MOQ)

We are offering rotary evaporator. The rotary evaporator principle is the most universal method, as it is an efficient, fast and gentle way to separate liquids. The rotating flask continuously covers a large surface area with a thin film, which is ideal for rapid heat transfer. Fortuitously, the film also ensures uniform heat distribution without local heating. the facility to work the unit under full vacuum further facilities evaporation at as low temperature as possible. These features, combined, renders rotary film evaporator to be ideally suited for evaporation of heat sensitive material. It is equally successful for evaporation of suspension in crystallization processes drying of powder / granule etc. salient features: table top model, sleek, compact with minimum footprint. very specific feature additionally incorporate & found useful in r&d areas such as continuous feed tube. High effective vertical condenser for maximizing recovery rates, provision for reflux distillation through reflux valve as an additional feature, total recovery of product condensate to recovery flask. designed especially for solvent separation-miscible & immiscible, crystallization. control panel located on the front of the unit thereby protecting the user from the hot water bath. heating bath features non-slip handles for safe up down movements of bath. At the time of power failure can also be operated manually. construction of vacuum seal is made of ptfe, which extends its life and reduce down time. indigenously developed vacuum seal mechanism in ptfe giving competitive edge against well-established rotary flask of international or other indian make. ip-55 insulation protection against dust & fumes.

Rotary Vacccum Evaporator

Get Price Quote

Rotary Film Evaporator

Get Price Quote

The rotating flask continuously covers a large surface area with a thin film which is ideal for rapid heat transfer. Fortuitously, the thin film also ensures uniform heat distribution without local heating. The facility to work the unit under full vacuum further facilitates evaporation at as low temperature as possible. That is to say, both boiling point and residence time are significantly reduced. These features combined, renders rotary film evaporator to be ideally suited for evaporation of heat sensitive material. It is equally successful for evaporation of suspension in crystallization processes, drying of powder granules etc.

Rotary Vacuum Evaporator

45,000 Per Piece

1 Piece (MOQ)

Large Scale Rotary Evaporator

Get Price Quote

Rotary Vacuum Evaporator

Get Price Quote

Laboratory Rotary Evaporator

Get Price Quote

Rotary Evaporator

Get Price Quote

We Bring Forth Superior Quality Rotary Evaporator that is Manufactured from Quality Components. These Rotary Evaporators are Easy to Operate and Ensure Optimum Performance. the Rotary Evaporators Find Applications in Various Laboratories. Moreover, It is also Available with Control Panel and Electrical Drives Suitable for Operation in Explosion Proof Zones as Optional.

Rotary Film Evaporator

Get Price Quote

We manufacture and export rotary film evaporator that is used with spherical evaporating flasks. Our range of rotary film evaporators is widely demanded in the international market owing to its qualitative features. We offer rotary film evaporator in various specifications.

Rotary Evaporator

Get Price Quote

A rotary evaporator is a device used in chemical industries & laboratories for the efficient and gentle removal of solvents from samples by evaporation.(rotavap/rotovap)The main components of a rotary evaporator are: A motor unit that rotates the evaporation flask or vial containing the user's sample. a vapor duct that is the axis for sample rotation, and is a vacuum-tight conduit for the vapor being drawn off the sample. a vaccum system, to substantially reduce the pressure within the evaporator system. a heated fluid bath (generally water) to heat the sample. a condenser with either a coil passing coolant, or a "cold finger" into which coolant mixtures such as dry ice and acetone are placed. a condensate-collecting flask at the bottom of the condenser, to catch the distilling solvent after it re-condenses. a mechanical or motorized mechanism to quickly lift the evaporation flask from the heating bath. Advanced frequency conversion and electronic speed regulation, to ensure stable operation of motor, and improve the evaporation and recovery rate. Height adjustable bath pan, and vacuum feeding, to reduce the damage of glass flask caused during rotation; ice-bath in the receiving flask during low-boiling-point evaporation, to reduce secondary evaporation. Due to the adoption of ball-milling port connection, the receiving flask can be easily assembled and disassembled, and can be sealed at high performance. Due to the adoption of high-temperature-resistant and corrosion-resistant long-acting precision sealing elements, the air tightness under the conditions of high temperature, high negative pressure and strong corrosion is ensured in the dynamic sealing process. The base plate, bath pan, main rod and crankshaft of the rotary evaporator are made of high-quality stainless steel; the rotary evaporator has attractive appearance and can resist to corrosion.

Rotary Film Evaporator

Get Price Quote