vibro screening machine

40,000 - 400,000 Per

Technical specification:-The heart of the Vibroscreen is its special heavy duty, Robust Motor, having out of balance weight at top & bottom. By changing their lead angle, various spiral-screening patterns are obtained to suit different application.It is also called Vibro energy separator.

Semi Automatic Rice Bran Centrifugal Separator

200,000 Per Piece

Best Deals from Separating Machines

Fab Air Classifier

300,000 Per unit

1 piece (MOQ)

We are offering fab air classifier. Applications: fab udhyog recommend a efficiency classifier design which enables efficient cuts at sizes, maximizes productive performance and minimises system specific energies. for an optimum system, it is essential that the maximum amount of product is recovered from the grinding mill discharge at the required size, and that fine particle that adhere to the coarse particle returns are effectively washed clear from this stream. features and benefits: •operating particle size range of 5 to 300 microns •precise on-stream control of cut-point by variation of rotor speed •low system resistance •low power consumption •adjustable secondary air system for optimization of classification efficiency •hardly no coarse contamination in fines •operates under negative pressure promoting dust-free environment •robust construction and build quality for long service life •minimum maintenance through robust design.

Pharma Vibro Sifter

105,000 Per Unit

Aluminium Gyro Screen

100,000 Per Piece

HYDINT MOISTURE SEPARATOR-SMART-2

2,457 - 2,730 Per Piece

1 Piece (MOQ)

Liquid Magnetic Separator

80,000 Per Piece

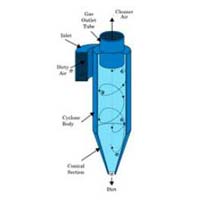

Cyclone Separator

Get Price Quote

Cyclonic Separation is a method of removing particulates from an air stream, without the use of filters, through vortex separation. Rotational effects and gravity are used to separate particle from the dust laden air.Cyclone body will be cylindrical in the top portion and conical shape at the bottom as shown in the drawing. The air stream will enter into the cyclone body tangentially in the top cylindrical with high velocity. The top portion of the cyclone body guides the air to move in circular pat in high velocity. A cyclonic effect (twister) will be created inside the body and the air stream move downwards in the heavier dust particles in helical pattern. The heavier particles in the air stream have too much inertia, while moving in cyclonic effect and move towards outer peripheral of the cyclonic effect in the air stream. When the particles are striking the inner surface of the cyclonic body, it will lose its momentum and fall down. In a conical system, as the rotating flow moves towards the narrow end of the cyclone, the rotational radius of the stream is reduced, thus separating smaller and smaller particles.Cyclone is called as pre collector in the dust extraction system. Cyclone has good efficiency in dust separation for large size particles and fibre dust particles. Cyclone separator will be used to segregation of items or products in the conveying systems. Cyclone separator MOC will be defined by the application and nature of dust to be handled.Cyclone separators widely used in Wood industries Flour mills Pneumatic conveyors Coir mattress Fibre glass Buffing & Polishing Boilers and furnaces exhaust Bulk drugs

Air Classifier

Get Price Quote

2 Piece (MOQ)

Air Oil Separators

Get Price Quote

Owing to our skilled team of professionals, we have emerged as a renowned manufacturer, wholesaler and supplier of Dust Collector Cartridge. Our experts use optimum quality raw material for manufacturing this dust filter along with modern techniques. This dust filter is checked on numerous parameters by our quality controllers in order to deliver a defect free range. Customers can avail this dust filter from us at nominal rates in a stipulated time frame.

Air Clasifier

Get Price Quote

We are offering air clasifier. Applications: fab udhyog recommend a efficiency classifier design which enables efficient cuts at sizes, maximizes productive performance and minimises system specific energies. for an optimum system, it is essential that the maximum amount of product is recovered from the grinding mill discharge at the required size, and that fine particle that adhere to the coarse particle returns are effectively washed clear from this stream. features and benefits: •operating particle size range of 5 to 300 microns •precise on-stream control of cut-point by variation of rotor speed •low system resistance •low power consumption •adjustable secondary air system for optimization of classification efficiency •hardly no coarse contamination in fines •operates under negative pressure promoting dust-free environment •robust construction and build quality for long service life •minimum maintenance through robust design.

Moisture Separator

11,000 - 18,000 Per Number

25 Set (MOQ)

Vibrating Classifier

Get Price Quote

We bring forth high quality Vibrating Classifier, which is manufactured using latest technology. Our Vibrating Classifier is known for its high performance and longer working life among the clients. The Vibrating Classifier is offered in varied specifications to suit the clients requirement. Features High performance Longer working life Rugged construction Superior quality Applications Flour mill Besan mill Corn mill Dal mill Maize mill Rice mill Soya flour mill

HYDINT Moisture Separator, Aluminium with Mechanical Auto Drain Facility, Model: SILVER+ADB

2,800 - 3,500 Per Each

1 Piece (MOQ)

Oil Mist Separator

Get Price Quote

We are ranked amidst the most sought after and reliable Manufacturers & Suppliers of Oil Mist Separator. Being customers’ most favored option in this domain, we deliver the certified range of Oil Mist Separator that is well-designed in the modern infrastructure, using cutting-edge technology. We are instrumental in offering qualitative, cost effective, experts certified Oil Mist Separator.More About Information of Oil Mist Separator : NAF air purification devices are based on a mechanical filtration and separation process that consist of a five stage pre separation in combination with a variable post-separation process. The pre-separation consists of an ideal adapted combination of metal mesh separators, filter fleeces, and, at its core, the long life separator. The post-separation consist of a H13 HEPA filter (separation rate > 99.95% based on partical size of 0.4μm). Because the preliminary separation is so extremely efficient, H13 filter can be used for a very long time. Special FeaturesNAF air purification devices are professional solution for collecting and purifying air that has been contaminated by Oil and emulsion mist Minimum lubrication mist And can be used as A compact single device for separating oil and emulsion mist from one mechining centre. A central or group exhaust system for separation of oil and emulsion mist from multiple machine tools in a production hall.

Vibro Sifter

85,000 Per Piece

1 Piece(s) (MOQ)

Screen Air Separator

Get Price Quote

This Pre-cleaner is mainly designed to cater to pre-cleaning of agro seeds at modern processing plants. It can be placed before storage silo or even in plant operations. Salient Features: The Screen air Separator is of positive eccentric, four bearing design type. High speed, vibrating screen which ensures accurate, high quality separation at high capacity. The adjustable feed hopper regulates feed as desired and uniform distribution of material across width of screen. The outboard bearing isolation mount combined with advanced balancing systems make the frame vibration less, allowing the machine to be operated on any structure. The outboard bearing isolation mount combined with advanced balancing systems make the frame vibration less, allowing the machine to be operated on any structure. Quick access clamps permit easy access for interior cleaning and faster screen changing. Optional stainless steel construction permits the machine to be used for food, chemical and other specialized application like de-watering. Ball compartments incorporated into the screen support grid allow an optional ball cleaning system. Several models are available for capacity up to 100 TPH and above on wheat basis. Optional — Variable Speed drive facilitates to adjust optimum speed for best cleaning results The Screen Separator may be equipped with various options. PRE SCALP UNIT is equipped with a short screen, somewhat coarser than the “top” scalp screen in the machine. This makes for scalping of the large over-size objects before the product enters the Screen. PRE-ASPIRATOR is used to remove hulls or dust and other light contaminants before the product enters the Screener, thus making the product more flow able at the start of the screening operation. POST ASPIRATOR is used when the finished product is to be the “plus” of the screen. This product is then discharged through the aspirator which removes dust or other light contaminants. FOUR DECK SCREEN SEPARATOR can be supplied for as high capacity as 100 TPH, with split-flow arrangement.SCALPER DRUM & SUTLI SEPARATOR can be provided at Feed inlet to remove bag Sutli jutes before feeding the material into Pre-Aspirator

multicyclones

Get Price Quote

The cyclone is a widely used type of particulate collection device in which dust-laden gas enters tangentially into a cylindrical or conical chamber and leaves through a central opening. When very large gas volumes must be handled and high collection efficiencies are needed a multiple of small diameter cyclones are usually nested together to form a multicyclone. Such systems are also customized for product recovery system along with pollution control equipment.

Multi Cyclone Separator

Get Price Quote

Being a leader in the industry, we are engaged in offering a qualitative range of Multi Cyclone Separator to our customers. Details: Multi-cyclone is the second generation mechanical dust collector after the cyclone. It is having multiple parallel cyclonic tubes inside the chamber which separate the heavy dust particles from the air stream. This is used as a primary separator to reduce the dust load on the bag filter or dust collecto

Air Oil Separator

12,500 Per Piece

Oil Separator

Get Price Quote

2901162600 - ATLAS COPCO OIL SEPARATOR , for Oil lubricated rotary screw compressor Atlas copco make GA series , high quality preferred by industries and big buyers gives excellent performance genuine quality

Vibro Sifter

Get Price Quote

The Vibro Sifter we offer is designed in compliance to cGMP complied using high grade SS 316 (Contact Part) & SS 304 (non contact parts). Vibro Sifter we offer is in demand owing to its dimensional accurate, enduring performance, resistance to wear and tear. Vibro Sifters are made available to the clients in secured packing within a stipulated time frame. About Vibro Sifter It is a circular gyratory screensConsists of Specially Designed Motor mounted vertically at the center of the base plate of the ScreenThe screen is in between feeding hopper and bowlThe material is fed on to the centre of top screenThe under size material passes rapidly through the screen during its travel to the peripheryThe over size material get continuously discharged through a tangential outletHas eccentric Top and Bottom WeightVibration is generated in three different planes along the vertical axis by means of a specially designed vibratory motor having off centered weights at the top and bottom end of the motor shaftThe angle of lead of the lower weight to the upper weight provides variable screening pattern & outputEquipped with PLC controller for minimum human intervention for optimum use Used To Separate solids from solids and liquid from solid

Vibro Separator

Get Price Quote

vibratory separator, vibratory screener, vibro screen machine, vibrating sifter, round separator, industrial sieves. In addition to applying standard screening equipments, Galaxy Sivtek Separator has the capability for offering custom made sieving screening machine. Separator provides effective, economical and efficient solutions to numerous process industries. Separator is designed for precision screening operations, to ensure separation of solid from solids and liquid from solid in coarse as well as fine sizes.

Condensate Air Treatment Separators

Get Price Quote

Vibro Sifter Machine

Get Price Quote

The machine is suitable for sifting the granules and powder. The machine is provided with a stainless steel screen. The screen frame is made out of S.S.316 qlty. The screen frame is made out of S.S.316 qlty. The unit is supplied complete with one S.S. sieve of any mesh. (To be specified while ordering) All contact parts are made out of S.S. 316 quality and M.S. body covered by S.S. 304 Sheet. Stainless Steel parts polished as matt finish. Complete unit as per our standard. Size: 20" Dia., 30" Dia.

Air and Oil Filter And Moisture Separators

Get Price Quote

Capitalizing on our cutting edge technology we are able to manufacture and provide filter and moisture separators for various industries. We are able to design wide assortment of filters as required in various industries. Some of our separators encompass of air filters, oil filters etc. We offer a wide array of air filters, oil filters and moisture separators used extensively in the industrial processes. Made from the best quality raw materials the goods are highly effective and durable with international standards. Some of these assortments are: Air Filters We offer a great variety of candle type filters for efficient filtration. Candle used for pre-filter shall be 40 micron rating and for post-filter 5 microns. These filters are simple and very much reliable for better results, which can be cleaned after certain time of intervals and can be re-used. Oil Filters We offer Activated Carbon Filtration for the removal of oil vapors and hydrocarbon odors. Maximum oil content remains after the filter less than 1 ppm at 40 degree celcius temperature and 7 kg/cm2 operating pressure. Moisture Separators We manufacture a great range of moisture separators with inlet and outlet connections screwed or flanged and drain connection and a vent connection. Compressed air enters the separator tangentially and passed through the demister pad made of stainless steel wire mesh. A water droplet impinges against each wire and settled in the bottom and separated it from the drain. For a better efficiency Automatic Moisture Drain Trap (ADT) can be provided at the drain for efficient separation.

Screen Air Separator

Get Price Quote

Oil Mist Separator

60,000 Per Piece

Moisture Separator

Get Price Quote

Description: IndoAnushka make Moisture separator with drain module is a value added solution for removal of moisture from the steam headers. Moisture separator with drain module consists of M.S. fabricated moisture separator with completely assembled drain assembly consisting of ball float steam trap, IndoAnushka make MAINTENO strainer with inbuilt blowdown valve and IndoAnushka make MULTIVIEW double window sight glass with deflector and 1 no. Isolating valve completely assembled with interconnecting piping and 1 no. Outlet nozzle as provision for bypass. Available Sizes: 15NB ONWARDS upto 300NB. Pipe Connections: ANSI 150, 300 & 600. BS-10 Table-H, J & K Limiting Conditions: For Moisture Seperator – Max. working pressure and temperature as per flange ratings. For Drain module – Max working pressure-13bars, Max working temp – 180 OC. Materials : Body & Baffles – M.S. Fabricated Trap – C.I with ss internals Strainer – CI with ss internals Multiview- M.S Fabricated Valves – CI

Filters and Centrifugal Separators

Get Price Quote

Tailored compressed air treatment All Kaeser filters and compressed air treatment components are specifically designed for use in combination with one another. Compressed air of every quality class is available ranging from general works air right up to foodstuff and pharmaceutical grade air. KAESER compressed air filters are also available for high-pressure applications up to 62 bar(g). Why use compressed air filters?On average, a compressor sucks in up to 190 million particles of dirt, hydrocarbons, viruses and bacteria with every cubic meter of atmospheric air. The compressor itself can only remove the larger particles and the majority of the contaminants remain in the compressed air. This means that for most applications careful treatment of the air is necessary: Clean, quality compressed air maximises air-tool service life, ensures that pneumatic machinery and control systems operate at the peak of their performance and keeps pipes & valves free from contamination. It therefore not only reduces service, maintenance and repair costs, but can also reduce initial investment costs. KAESER filters ensure a dependable and cost-effective source of quality compressed air Compressed air filters from KAESER KOMPRESSOREN are ideally suited for use with our compressors and compressed air dryingsystems. This ensures dependable compressed air treatment and exceptional efficiency. Air Flow Rate : 0.58 to 248 m³/min (20 CFM to 8758 CFM)