WIP / CIP System

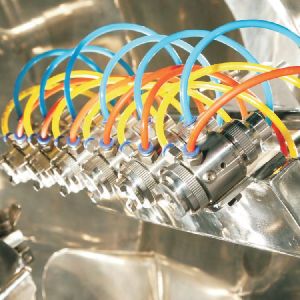

Skid mounted WIP/CIP system comprises of selection of different wash media inclusive of cold water, hot water, detergent wash and air purging. To avoid cross contamination, a high pressure multi stage pump is provided to obtain desired pressure for water for effective cleaning of internal wall of PAN with auto drain system. The wash cycle can be generated according to product nature through Programmable Logic Controller.

...more

vacuum transfer system

800,000 - 850,000 Per Piece1

Based on the principle of suck and dump mechanism, a unique system is designed for unloading of pellets / tablets once the coating process is over. This trolley-mounted vacuum operated system saves time and improves overall process productivity. This specially designed auto - loading & unloading system comprises product holding vessel with filters and having provision of suction and discharge of material. It also consist of pneumatic operated valves and timer based controller having separate control panel to set suction and discharge timing sequences. All nozzle connections are provided with pneumatically operated valves.

Brand Name : Solace

Driven Type : Electric

Automatic Grade : Semi Automatic

Power : 1-3kw

Voltage : 380

Load Capacity : 100

Type : Direct

Weight : 100-1000kg

Structure : Ss

Warranty : 1 year

Country of Origin : India

Warrenty : 1year

...more

tablet compression machines

tablet coating machines

200,000 Per Piece

1 Piece (MOQ)

plc based OPERATING SYSTEM

Brand Name : Indian

Type : Semi Automatic

Warrenty : 1year

Country of Origin : India

After-Sales Service Provided : 1 Year

Weight : 500-1000kg

Voltage : 440V

Usage/Application : Coating

Power : 3-5kw

Automatic Grade : Semi Automatic

Condition : New

Driven Type : Electric

...more

Square Cone Blenders

Solace Square Cone Blender is used in Pharmaceutical Industry mainly for mixing of granules and powder. It is steady in transmission, reliable in structure, fully capable, highly uniform and homogeneous in mixing.

...more

Spiral Fluid Bed Processor

This latest advanced and automated spiral action movement fluid bed dryer / processor is specially designed in modular construction. The Patented (Technology) air distribution plate creates spiral air flow pattern which gives spiral movement to the product that ensures fast fluidization and uniform heat transfer.

...more

spheronizer

Unique Extruder Spheronizer comprising of charging hopper, extruding chamber, partial reduction device and screen plate. The lumps are fed from charging hopper. The material flows into extruding chamber and passes through screen for extrusion. The lumps are converted into cylindrical shape. Extudants of different length which drops into spheronizer are cut by centrifugal turning mesh plate and are converted into short spherical granules.

...more

Solace Solid Pan Coater for Tablets

The unique design of Solace Solid Pan Coating System offers better performance and flexibility of coating requirement over perforated pan system. The Solid Pan Coating System caters to the rising coating demand from an advanced Pharmaceutical Industries requiring the compliances to the WHO, GMP, CGMP standards. The Solid Pan Coating Technology offers a precise coating of any size and shape of tablets, micro tablet, Granules and pellets for film (Aqueous, Non aqueous) as well as sugar coating. We offer advanced automation by using latest PLC & touch screen graphic MMI, to monitor various processes like air distribution, temperature, humidity, auto cleaning process, Interlocking Security, Auto loading & unloading and CIP/WIP. Latest PLC control enables the user to do multi tasking through PLC and colour touch screen graphic MMI. The PLC programme ensures security, interlocking, auto loading and unloading & CIP/WIP with ease. Film Coating Film Coating system comprises of chokeless Imported Spray Gun & Compact Peristaltic Pump for constant and precise flow rate from each gun. Sugar Coating Sugar coating system comprises of sugar solution dripping nozzles and pneumatically / electrically operated high pressure diaphragm type pump.

...more

Solace Coater for 1000 Kg. batch

The Solace Auto Coater has been designed to carry out most perfect and uniform coating with the minimum intervention of the operator. Solace Auto Coater is designed as a free standing, totally enclosed unit, with inbuilt multi nozzle CIP system.

...more

Solace Coater

Solace Auto Coater has been designed to carry out most perfect and uniform coating with the minium intervention of the operator. Solace Auto Coater is designed as a free standing, totally enclosed unit, with in built WIP system. Its interiors are accessible through leak proof doors provided on rear, left and right sides. The unique perforated coating pan design utilizes a totally enclosed, highly efficient air flow system for maximum drying uniformity and minimum process time. Process air flows through the inlet duct which is directed down through the product bed. The air exits through the exhaust plenum located under the tablet bed. Creating a negative pressure in side the coating pan. Fully automated rotary valves on inlet and outlet ducts located at technical area controls the quantum of inlet and outlet air as per batch size. Matching solution pump and four point all SS316 air borne spray guns optimize the coating process. Highly sophisticated, accurate and precise positive displacement / self priming peristaltic pumps from UK / USA based Watson-Marlow / Master Flex ensures the process stability and quality of the end product. All SS spray guns are chokeless in operation with automatic nozzle cleaning system, adjustable spray width and automation controls make them suitable for the application of aqueous, organic solvent based film coating, sugar solution coating can be done in the same machine with bypass air duct, sugar solution driping nozzles and jacketed solution tank. Solace automated PLC based process control system with necessary hardware and software is designed to meet the requirement of process. The control parameters include system monitoring, control, feed back, data acquisition and processing. It Provides total security and can easily add or delete product recipe with proper password access. Solace customizes the operator interface graphic according to the customer’s requirements.

...more

sifters

Mechanical Sifter is a highly dependable equipment having multi-deck facility to segregate upto three different sizes of powder / granules according to process requirements by selecting the desire porosity of mesh net. Vibro Sifters Vibro Sifter is an ideal equipment having multi-deck facility to segregate upto three different sizes of granules as per process requirement. By selecting the desired porosity of mesh net, the different section of the equipment has special arrangement that permits complete sieving of the material.

...more

Rapid / High Shear Mixer Granulator

Practically the very first equipment of Granulation Suite, it sets the tone of entire granulation process. An engineering feat, executed with perfection, it mix, chop to increase the proper drug distribution and to obtain even size granules. Controlled through PLC, its mixer and chopper blades are proper in design, solid in strength and are perfectly aligned. The Conemil at the discharge port ensures the uniformity of the product without lumps, that is, an absolute essential requirement for next process. While the mixer blade mixes the mass homogeneously, the chopper located at right angle to mixer cuts the formed lumps disperse the drug, thus ensures even granulation of the mass.

...more

Post Bin Blender

Post Bin Blender can automatically finish the whole process of mixing. The equipment is constructed according to cGMP principles and is manufactured from AISI 316L grade. The equipment can be used for various size batches applying different sizes of bins. The Bin Blender comprises of post bin mounting arm hydraulic bin lifting mechanism, variable frequency drive arrangement, auto braking system for perfect positioning of bin after stop command and PLC control.

...more

Multifunctional Lab Fluid Bed System-2

Integrated functions like drying, granulation, particle coating, pelletizing process can be performed by selecting the different attachment in a single portable machine. It maintain evenness and recurrence of product quality, which reflects as ideal balance between production efficiency and product quality. In the process of fluidization the material floats in the air and remains in full contact with heated air. The top and bottom spraying system and perfect selection of attachment makes the fluid bed a multi purpose processing equipment. Advantages Single unit with multiple functions Easy interchangeability of selected attachment Smart PLC control Touch screen with graphic display Process DATA printout facility Fully compliance with cGMP norms Scale up / reproducible model

...more

Multi- Functional Fluid Beds

We are offering multi- functional fluid beds. These multi-functional bed processors are an excellent choice for granule or pallete coating. Special cartridge filters mounted on inside top assure no escape for the product. These filters are autocleaned by air purging controlled through plc. Specially designed air distribution system and spray nozzles offer the latest in coating technology. Rapid and uniform drying results in perfectly smooth and dimensionally controlled coating of the product.

...more

Multi-Functional Fluid Beds

These Multi-functional Bed System is an excellent choice for granule or pellet coating. Special Cartridge Filters mounted on inside top assures continuous fluidization. These Filters are autocleaned by compressed clean air controlled through PLC. Specially designed air distribution system and spray nozzles offer the latest in fluid bed technology.

...more

Lab Rapid Mixer Granulator

The compact model of RMG is very easy to handle. The powder is charged into the bowl for desired time and is wetted by a liquid or blinder from the top nozzle. At the same time the material is mixed by a horizontal mixer and chopped by a vertical chopping blade. The wet granules are normally discharged into a Conemil before they are dried by a fluid bed dryer. Advantages Very compact in size Produces round and even granules Mixing and granulating in one step Automatic discharge Compressed air seals for mixer & chopper blade Compact bowl design Smart PLC Control Saving of binding liquid Full compliance with cGMP norms

...more

Lab Interchangeable Tablet Coater

Compact automated & inter changeable coater designed to process all size & shapes of tablet for smooth & perfect coating with facility of different size of pan. Machine is equipped with highly polished perforated pan having reverse spoon type baffles for perfect movement of tablets for perfect coating with SS choke less Spray Gun, Peristaltic Pimp, In-buit air preparation & filtration unit which is controlled through smart PLC by coloured touch screen. Advantages Compact design occupy less space Specially designed inbuilt air distributing system. Easy interchangeable facility for quick changeover of different size of pan as per batch size. Specially designed reverse spoon type baffles for perfect tablet revolving. The components can be easily dismantled for cleaning. High productivity with good finish, shine and smooth surface.

...more

Lab Extruder Spheronizer

Unique Extruder Spheronizer comprising of charging hopper, extruding chamber, partial reduction device and screen plate. The lumps are fed from charging hopper. The material flows into extruding chamber and passes through screen for extrusion. The lumps are converted into cylindrical shape. Extudants of different length which drops into spheronizer are cut by centrifugal turning mesh plate and are converted into short spherical granules. Advantages Perfect production efficiency to achieve good density equal extrusion. Wide range of mesh plate to achieve cylindrical extrudants. PLC controlled panel with perfect interlocking.

...more

fluid bed processors

We are offering fluid bed processors. Features operator’s control single multipoint spray guns watson marlow peristaltic pump cgmp compliant. 2bar construction. single pot operation i.e. Mixing, granulating & drying. three stage filtration i.e. 10 micron5 micron 0.3 micron. precise temperature control i.e. ±1°c. single multi point binder spray arrangement. minimum spray loss. plc controlled binder spray rate, wip and automated powder loading. explosion relief flap. flameproof construction.

...more

Fluid Bed Processor / Granulator

Fluid Bed Processor / Granulator Different powders of varying bulk density can be homogeneously mixed, processed and dried in Solace Fluid Bed Processor / Granulator. The turbulence required to mix the ingredients thoroughly is created by the unique design of the perforated plate located at the bottom of product container. The binder is sprayed in exact pre measured quantity at regular interval during Fluidization.

...more

fluid bed granulator

Different powders of varying bulk density can be homogeneously mixed, processed and dried in Solace Fluid Bed Processor Granulator. The turbulence required to mix the ingredients thoroughly is created by the unique design of the perforated plate located at the bottom of product container. The binder is sprayed in exact pre measured quantity at regular interval during Fluidization.

...more

Fluid Bed Dryer

Different powders of varying bulk density can be homogeneously mixed and dried in Solace Fluid Bed Dryer. The turbulence required to mix the ingredients thoroughly is created by the unique design of the perforated plate located at the bottom of product container.

...more

Fluid Bed Dryer

We are offering fluid bed drier. Moisture content of the mixed ingredients plays the most vital part in getting the right finished product. For example no tablet can be formed even with the best of the ingredients unless the moisture content of the mass is maintained within very tight tolerances. Solace fluid bed dryers are the recognized leaders in the industry for giving un-surpassable performance. The correct volume, velocity, direction and the temperature of the clean air is maintained throughout the fluidization by high end design of the retarding and expansion chambers, the design and the pitch of the perforations of the plate at the bottom of product container, the leak-proof fluidization space and the scientifically chosen material of the filters.

...moreBe first to Rate

Rate ThisOpening Hours