Tank Weighing System

Get Price Quote

1 Piece (MOQ)

Optima Weightech Private Limited is a well-known manufacturer and supplier of weighing systems and scales. Our tank weighing system is built to be a low-profile solution for high-capacity vessel weighing applications. The compression transducer, mounting hardware, and suspension are all combined in one arrangement to support the vessel and manage the load application.Our tank hopper weighing system is appropriate for both indoor and outdoor applications. These weighing systems include a strong Indicator as well as load cells. All gear is built to withstand tough environments and allow easy installation and maintenance. Weigh indicators, are built using cutting-edge ultra-modern technology to accommodate various degrees of automation, including interfacing with PLCs or automating the entire process, among other things. Our tank weighing scales are intended for weighing the amount of liquid or solid material that has been poured into or released from industrial tanks, silos, bunkers, and mixers.Features : Easy maintenance Fully Stainless steel Wide choice of Indicator options Easy to install Lift off protection Applications : Paint Cement Fertiliser Oil Grain Ethanol

Tank Weighing System

50,000 - 150,000 Per Sets

1 Set(s) (MOQ)

Best Deals from Weighing System

Weighing Batching System

Get Price Quote

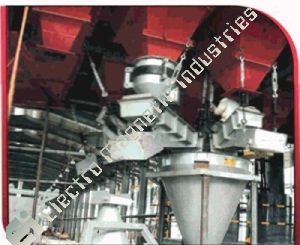

We are a renowned Manufacturer, Exporter, Importer and Supplier of Weighing Batching System from Gujarat, India. The Weighing Batching System we offer can handle a capacity of from 10 ton/day to 85 ton/day, and at an accuracy 99.9%. Our Systems are widely preferred owing to their increased output, product consistency and quality, less spillage, and ease of operation due to less dusting. We are offering Weighing Batching System at reasonable rates. Salient features of our systems : Labor saving Minimum wastage Quality consistency Value addition to end product Eco friendly plant Low energy consumption Less material handling Easy maintenance & quick replacement of wearing parts Production data generation in PLC & SCADA based system High tech sensor technology integration Market development & competitive advantage Note : We provide control panels as a part of project which may include PLC, AC/DC drives, VFD etc. as per project requirement.

Online Weighing systems

Get Price Quote

Online Weighing systems are ideal for use wherever bulk weighing is required. The Dual Scale Bulk Weighers consists of two weigh hoppers side by side, all contained in one structure. A continuous feed stream allows one hopper to fill while the other is discharging, thus eliminating the need for an upper chamber. The two measuring hoppers are thus alternately filled, measured and discharged. This substantially reduces the height of the entire system. This arrangement offers advantages over conventional bulk online weighers designs because of smaller draft sizes which decreases product damage caused by impact loading and surging.

Tank Weighing System

Get Price Quote

Our Tank Weighing Systems are designed for weighing amount of liquid or solid material filled into or discharged from industrial tanks, silos, bunkers and mixers. These systems can be supplied with stainless steel and alloy steel load cells, available right from 20 kg to 500 ton capacities.Oil-proof, water proof anti corrision loadcell which is suitable for multiple environments.

WEIGHING & BATCHING SYSTEM

Get Price Quote

We specialize in computer programming, industrial technology, industrial Controls, batch process, automation systems, weighing, custom programming, GSE scale indicators, compounding, blending, recipe management software and inventory management systems.EMI Solutions, has achieved a reputation in the industry for the excellence of their “automation “ products and services. The systems we provide to our clients are very reliable, user-friendly and flexible and most importantly, they are customized to the specific needs of each customer.EMI Solutions’s commitment is to provide its customers with state-of-the-art technology and service of the highest quality. Each phase of the project is professionally monitored to ensure complete customer satisfaction. We take pride in our innovative solutions, design, technology, installation, and service. Understanding our customers’ needs and expectations is the key element of our success and continued customer loyalty. EMI Solutions Products and ServicesIn addition to our standard array of products. EMI Solutions will design the system that meets your needs.Fully Automated Multi-Station Batching System:Ours complete Batch Process Control Data Acquistion Software provides an automated batching/blending production line.Inventory Management and Process Scheduling Software :Ours Complete Inventory Management System provides real time tracking of inventory from raw materials to the finished products.Help File Development/Web Page Design:We can customize your programs with pages designed with systematic instructions for navigrating through even the most complicated programs. We can custom design a web solution suitable for any small of large business. —-Automated Batching Systems for Material Handling —- Ingredient Masters’ Automated Batching Systems substantially improve the efficiency of powder materials handling. Custom-engineered systems increase output and product consistency, eliminate waste, and generated production data.Automatic powder materials handling systems manufactured by ingredient Masters use off-the-shelf hardware and software to prevent issues with proprietary equipment and platforms and facilitate easy maintenance. The metering systems and powder blenders used in our system are recognized worldwide for highest reliability. —-Key features of our materials handling systems include:—- Turnkey system design, engineering, manufacturing, installation, commissioning, and training are provided Semi automatic to fully- automated systems that include metering and powder blenders. RS-232 output Local network compatible PLC/PC control Scaling, metering, conveyors, specialized product transfer equipment Integral dust collection Integrated bar code / RFID for full product traceability Systems, as well as metering, operator interface and powder blenders and ISO compliant Ongoing technical support Upgrades to maintain future technology Inventory rotation (FIFO) Ingredient Master provide Custom-Engineered Solutions for Dry Powder Handling.

Online Weight System

42 Per Piece

electronic weighing system

Get Price Quote

electronic weighing system, stainless steel tanks, Weighing System

electronic process weighing system

Get Price Quote

electronic process weighing system

Tank Weighing System

Get Price Quote

Tank Weighing System, Truck Weighbridges, Truck Weighbridges, Scales

Weighing System

Get Price Quote

Weighing System, Electronic Weighing Scales, Giloy Powder

Tank Weighing System

Get Price Quote

Tank Weighing System, Electronic Weighing Balance, Laboratory Balance

bulk weighing systems

Get Price Quote

bulk weighing systems, bagging machines, Gross Bagging Machine

hopper weighing system

Get Price Quote

hopper weighing system, Lose Weight Feeder, Bagging Controller