Spray Lacquer Coating for Concrete Materials

Get Price Quote

1 Barrel (MOQ)

Spray Lacquer for Concrete Materials ( 50 Ltr & 220 Ltr ) Details :- Colourant is a manufacturer of Lacquer or Concrete Lacquer are basically coating which is high solids and it is very crystal clear. Spray lacquer is very fast drying helps to protect the paver surface,Our coating lacquer enhances color & shine and tiny pores on the paver surface.This product is mainly used for beautifying and protecting the surfaces of life, masonry, and concrete. All the mentioned surfaces need a fine finish concrete lacquer gives it to them. The lacquer actually protects the floors of the garage and drives its oil stains away. It eliminates the freezing dusting thaw problems of concrete. It also helps to protect the barbeque areas and patio from the grease stain of food etc. It is superior for stain resistance abrasion resistance, and sunlight resistance qualities.

POLYMER AND CEMENTITIOUS COATING

Get Price Quote

NEOCRETE range of BONDING AGENT products are specially designed, integral compounds used as additive for modified portland cement composition. Neocrete modified mortar has improved physical strength, superior adhesion to old concrete, masonry, brick and other surfaces. For meeting different needs of application grades based on: I) aqueous dispersion of Acrylic Polymer, II) carboxylated styrene butadiene co-polymer latex etc are available in this range. The products finds extensive use in building industry as an adhesive / additive to concrete & plasters / as an universal bonding agent / as a cementitious coating. Features: Imparts improved bond / impact strength. Increases mortar wear resistance. Increases mortar flexural & tensile strength. Resists Mild Chemicals, Grease, Acids & Alkalis, Low permeability. Improves adhesion & surface hardening. Benefits: Perfect for repair. Ideal for rubber wheeled traffic. Reduces Cracking. Durable & Prevents concrete decay. Finds use in Waterproof sealing & Lining of tanks. Excellent bonding to building substrates & Limits wear & tear.

Best Deals from Epoxy Coatings

Ceramic Thermal Insulation Membrane Coating

Get Price Quote

We are offering ceramic thermal insulation membrane coating. Sahnstherm ceramic thermal insulation membrane coating for residential & work place protection from heat is used for keeping inside of premises cool by preventing heat transfer and permeation of heat and it provides convenient and comfortable living space. It reduces building decay and prolongs maintenance cycle. It protects buildings from thermal stress resultant structural or building damage. It offers elastomeric water proofing, seals and prevents cracks and leaks.

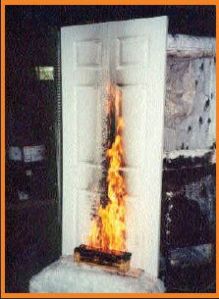

Passive Fire Protection Coatings

Get Price Quote

Fire protection is important for : Personnel protection – giving people time to escape or shelter from the effects of the fire Asset Protection–minimizing damage to the assets before f ire services arriving. Fire strikeswhenleast expected.The speed at which the fire travels or propagates even a small accidental fire or electric spark caused by short circuit is sufficient to create huge, immeasurabledamageto the safety of people and properties.The fire can start fromexternal source or internal source, just from anywhere and without warning. Fire takes advantage of unprotected surfacesandareas concealed fromfire fighters. The consequences - overwhelming heat, suffocating smoke, loss of time, damage to items of sentimental value and above all, the loss of life. The insurance company may able to replace the materialgoods, but there are fewthings thatmoneysimply cannot replace.The conventional paints coated over structural steel, concrete andwooden surfaces are flammable and indeed act as a fuel which aid in spreading of fire. The intense heat conducted through metal ignites the paint and combust spontaneously even if not subjected to a flame directly. In the event, of fire , the winning time is crucial in evacuating the peopleandlimiting theamount of structuraldamage.There isnosecondchance with the fire. Onehas todoit right first time. How Monarch's FlameGuard coating protects in the event of fire?Monarch's FlameGuard fire retardant intumescent coatings offer ultimate protection in extensive applications like Industries, Institutions, Corporate houses, Show rooms, Residences, Schools, Dormitories, Hospital Care, Nursing Homes, Hotels, Motels, Retail stores, Restaurants, Transportation etc., on structural steel, concrete, cables, wood, rubber, PVC, canvas, gypsum board, polyurethane foam, wooden surfaces, joists, beams, acoustic tile, rough and finished timbers, open surface panel board, previously painted wall board, hardwoods, softwoods, drywall, SPF plywoodand OSB etc.,This coating after application dries quickly toamatt finish .Oncontact with fire or excessive heat, the coating puffs up (intumesces) to several times thicker than original coating film, forming a sponge - like cellular foam insulating char layer and reduces available oxygen to the surface. Intumescent is a substance which swells as a result of heat exposure, thus increasing in volume, and decreasing in density.An insulating char of lowthermal conductivity that reduces heat transfer to substrate and slows the temperature rise of the substrate. The product works by cutting off oxygen fromthe fuel source inhibiting the combustion process in the immediate vicinity of the area and reduces the transmission of fire, heat and smoke to the protected area like fire retardant jacket during and after exposure to fire. Even after prolonged exposure to a fire the coating is not destroyed and continue to shield the substrate by forming lowconductivity carbon char that act as a barrier between the fire and the substrate. This substantially decreases the temperature rise, smoke generation and finally insulates and protects the substrate from theheat of the flame.The rating of fire retardant coatings depends on the intensity of the flame, type, coating thickness and other variables.More thickness of the coatings increases fire protection duration. The coating adheres tightly and fits to any size and shape of the substrate. It produces neat, attractive and paintable finish. The coatings are non-toxic, asbestos freeandresist cracking or crumbling. Active Fire Protection Vs Passive Fire Protection :Active Fire ProtectionMethods that require a certain amount of motion and response in order to react to put out the fire by locating smoke, % ames or heat, eg. Smoke & Heat extraction systems, Sprinkler systems, Fire extinguisher systems, Gaseous cleanagents, Fire$ ghting foam.Passive fire protectionMethods that contain, minimize the impact, or slow the spread of the fire. Contrary to active $ re protection the coating systembecomesan integral element of structural $ re protection and fire safety in buildings within a specified fire compartment aswell as ensuring that the load bearing capacity of the fire exposed structure is not reaching a critical level, the passive type does not need a response before reacting tothe fire eg. Intumescent coatings,Retardant coatings,Resistive coatings,Ablative coatings.CABLE PROTECTIONIntumescent fire protection coating for combustible single & bunched electrical cables and cable trays Flame Guard CP is a water-based intumescent coating which is designed to prevent ignition, flame spread & smoke emission along the jacketing of electrical (or other) cables and to provide a thermal barrier for protection against heat damage. FlameGuard CP will also prevent a short circuit within an electrical cable from starting a fire and will help identify the location of such a short circuit by forming an intumescent char at the spot. The coating can be applied to grouped cables or single cables.When exposed to flame or to a temperature above 175ºC, the coating formsa protective intumescent char. (This char shouldberemovedcompletelyandclean cables should be recoated if intumescences should occur). The coating foams up under the effect of heat to form an insulating layer.There isnosubsequent burning of protectedcables after the directeffect of fire hasbeenhalted.STRUCTURAL STEEL PROTECTIONFlame Guard ZP - PrimerEpoxy based zinc rich primer for fire protection coating for structural steel.Toprotect steel against corrosion&prepare the surface.Flame Guard SSP - Base CoatDuring fire when the structural steel temperature approaches 538°C it lose 60% of its yield strength andmay lead to the building collapse. FlameGuard SSP Base Coat – coated to desired thickness prevents steel structures from crossing the critical temperature of 538°C, thus delaying the collapse of loaded steel structures for up to 2 hours and providing time for evacuation & fire fighting. The smooth fibre free robust decorative surface allows the architect to use the structural steel work as an integral part of the building design. Rapid installation with typically DFT's below2mm, appearance of the structure is preserved without affecting the load bearing calculations. Incase of fire, the film expands tomany times its original film thickness.This provides an insulating foam-like coating or char toprotect steelwork againstheat build-upandthe effects of fire.Flame Guard SSP - Top CoatThin film high solids intumescent coating provide maximum protection & enables a high quality finish to be obtained similar to conventional decorative paints.Ahard decorative self-extinguishing, fast drying finish to seal the basecoat & provide an attractive high quality finish. Recommended as a top coat over FlameGuard SSP Base Coat for optical reasons and moisture protection. The coating facilitates as sealer function to prevent early degradationandinactivation of intumescent layer.Available in variousRALshades.BUILDING INTERIOR & EXTERIOR PROTECTIONFire Resistive/Retardant Paints to delay ignition/surface burning for Interior & Exterior Substrates Flame Guard FRP is premium qualitywater based, nontoxic thin film fire retardant paint formulated to delay ignition for 10-15 minutes and reduce surface burning rate of interior substrates, including gypsum board, composite architectural panels, oriented strand board and other wood products. This product is suitable for residential/multifamily, commercial for bothnewandreconstruction projects.High performance epoxy intumescent fire protection coating systemThe product is a high build, two pack material providing excellent durability combined with excellent corrosion and f ire protection for a long period of time for structures, pipe work, vessels and fire resistant divisions from the effects of hydrocarbon pool and jet fires caused due to petrol, diesel, petrochemicals and gases, cellulosic fire etc., primarily intended for use in high risk environments such as oil, gas, petrochemical and power generation industries. Suitable for both offshore and onshore environments. The coating thickness required for protection is normally specified in the range of 4-20 mm. To be used as mid coat as part of a complete system in atmospheric environments followed by weather resistant aliphatic polyurethane finish coat, MonoGuard PCG. The coating facilitates as sealer function to prevent early degradation and inactivation of intumescent layer.Depending on the actual exposure of the coating system,various primersandtopcoats canbeused in combination with this product. Base Coat - FlameGuad ZP - Primer Intermediate / Mid Coat - FlameGuard EIC Top Coat - MonoGuard PCG - Aliphatic Polyurethane top coat. WOOD PROTECTIONSingle component, chlorinated water resistant intumescent clear coating that contains highly effective fire retardants to reduce flame spread during the event of fire. The coating can be used over painted surfaces, fiber insulation, polyurethane foam,wood,andother combustible surfaces without compromisingonaesthetic appeal. On curing it forms a clear, non-yellowing, water resistant fire retardant f inish that protects the substrate from combustion and heat. The coated surface retains its original appearance and in addition protected by thewater & weather resistant properties. FIRE COMPARTMENTATION AT ELECTRICAL & MECHANICAL SERVICE PENETRATIONS THROUGH WALLS, CEILINGS & FLOORSWhen fire resisting compartments are created to contain fire and smoke from spreading within building structures, this also presents a parallel threat as most concealed activities between fire resisting walls and f loors are interlinked. The importance of sealing gaps in this type of construction is therefore vital to ensure the compartmentation systems work to their maximum ability to save life and property. Such gaps are typically at service penetrations through walls and floors, but also include gaps left for structural movement and gaps left due to poor workmanship. The integrity failure occurs when cracks, holes or openings occur through which flames or hot gases can pass. Insulation failure occurs when temperature rise on the unexposed surface of the service, on the unexposed face of the building element25mmfromthe penetration or the seal itself exceeds 180°C . FlameGuard EFMplaysanmajor role inmaintaining integrityandinsulation.FlameGuard EFM Mortar is a fire rated load bearing system providing up to 4 hours (for 200 mm thickness) fire protection to compartment walls, ceilings and floors around large electrical and mechanical through service penetrations like HVAC ducts, plastic pipes, and where electrical services have been installed. Whilst curing, the mortar expands by approximately 1%ensuring a tight seal around penetrations and within the opening. It is designed to maintain the fire resistance of compartmentwalls and floors.When mixed withwater it can be poured or troweled into service penetration openings preventing the passage of flame, smoke and toxic gases for periods of up to 4 hours for 200mmthickness and thermally insulating f ire seal.Themortar is pre – mixed dry blend, consisting of inorganic fillersandfoamedperlite.MINERAL WOOL BOARDFlameGuard MWB is a f ire & heat resistant mineral wool boards coated on both sides with FlameGuard CP intumescent coating, affixed with FlameGuard EFMexpanding sealant, to prevent the passage of fire and smoke and the transfer of heat. Final aesthetic protective top coating of FlameGuard FRP for moisture protection. It is specifically designedfor sealing aroundcable&service penetrations inwallsand floors.Dimension: Outer Boards – 2 x 595mm x 1195mm x 23mm (Each Board 0.71 Sq mtrs). Size subject to change. Infill Rockwool Insulation pre – coated with FlameGuard Intumescent coatings > 1mm DFT – 4x 1mtr x 0.50mtr x 50mm (0.50 sq mtr each infill insulation panel).

Rotary Screen Coating

Get Price Quote

In rotary screen coating, the patterns are normally dots and open or closed surface structures. The adjustment of weight is done by open areas and thickness of the screens. Suitable for low to high viscosity products Modification with additives Application as paste and stable, metastable or instable foam Wide selection of rotary screen patterns

Foundry Coating

Get Price Quote

Foundry Coating, Bakelite Kettle Handle, bakelite molding machine

Boiler Tube Coating

Get Price Quote

Boiler Tube Coating, Thermal Spray Coating, Agro Products

thin film coatings

Get Price Quote

thin film coatings, optical components optical lenses, precision lenses

hygine coating

Get Price Quote

hygine coating, safety coating, structrual coating

Powder Coating

Get Price Quote

Powder Coating, Sheet Metal Components, Punching, Cable Trays

Epoxy Coating

Get Price Quote

Epoxy Coating, Sulphur, Sulphur Powder, Iodised Salt, Industrial Salt

Powder Coating

Get Price Quote

Powder Coating

press coating

Get Price Quote

press coating, Earthing Rod, Cable Trays, Sheet Metal, Powder Coating

anti-corrosive coatings

Get Price Quote

anti-corrosive coatings, Exterior Paints, Construction Chemicals

pipeline coatings

Get Price Quote

pipeline coatings, Sealants, concrete repair materials, Grinding Aids

cereamic coating

Get Price Quote

cereamic coating, abrasive, pvc solvent, Sealant, Wood Preservative