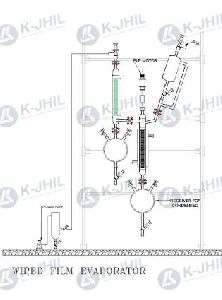

wiped film evaporator

We are one of the trusted companies in India, which is manufacturer and exporter of Wiped Film Evaporator. The system we provide is based on latest technology, which is mechanically designed and tested by our engineers so that it can give the best of its performance. Our system is fully customized to meet our client’s requirement.Wiped Film Evaporator is a Thin Film Evaporator and consists of a jacketed glass / SS / other corrosion resistant pipe section in which is rotating a corrosion resistant PTFE / SS / other corrosion resistant wiper system with suitable rows of blades supported by suitable bearings.These give a high wiping frequency and therefore, an optimum renewal speed of the boundary layer, which are pre-requisites for thorough mixing of the liquid film and for high evaporation rates. The wipers are forced against the evaporator wall by centrifugal force, and this can be varied via the speed of rotation of the drive, depending on the viscosity of the liquid.Features : Made of corrosion resistant materials. Lowest possible working temperatures possible. Very low residence time. Visual observation while using Borosilicate glass. Low Hold-up. Modular system for all glass components that permits flexible design and rapid assembly of the unit. Digital control of motor speed. High level of automation (optional)

Type : Wiped Film

Material : Aluminum, Titanium

Certification : ISI Certified

Application : Industrial

Voltage : 220V

Finishing : Polished

Phase : Single Phase

...more

thin film evaporator

We are one of the trusted companies in India, which is manufacturer and exporter of Thin Film Evaporator Manufacturer. The system we provide is based on latest technology, which is mechanically designed and tested by our engineers so that it can give the best of its performance. Our system is fully customized to meet our client’s requirement.Thin Film Evaporator made of glass for the gentle distillation of thermal sensitive products. Thin Film Evaporators are used in Chemical Laboratory &Industry for the production and processing of low-molecular as well as micro molecular substances. Because of the thermal sensitiveness of such products, this separation method is applicable.The medium which is to be distillate is exposed only for a very short time to the heating substance because of the film, which is created by the wipers, can evaporate very quickly. The residence time of the medium on the heating surface is a matter of seconds, thus essentially less than in a circulating evaporator. The glass construction of the evaporator permits all procedures to be exact visually made in the evaporating.

Type : Thin Film

Material : Aluminum, Titanium

Certification : ISI Certified

Application : Industrial

Voltage : 220V

Finishing : Polished

...more

Sulphuric Acid HCL Gas Generator

32,000 - 73,000 Per Piece

Our generator helps in the generation of the HCL gas, Sulphuric Acid Route which fulfils the necessary requirements in pharmaceutical industries. The product is made using high grade components and designed precisely with safety norms. We check the product to ensure its defect free performance.Features : Easy to maintain Premium quality Compatible For certain applications e.g. in bulk drug/pharmaceutical industry HCL gas is required in anhydrous state for critical reactions where moisture cannot be tolerated. Such users generate anhydrous HCL from commercial grade for their captive consumption. Several methods have been adopted but generation through SULPHURIC ACID ROUTE is the most reliable and handy technique.

Type : Automatic

Certification : CE Certified

Application : Industrial

Voltage : 220V

Power : 1-3kw

Driven Type : Electric

Warranty : 1 Year

...more

Sulphuric Acid Dilution Plant

The acid should be added slowly to cold water to limit the buildup of heat. If water is added to the concentrated acid, enough heat can be released at once to boil the water and spatter the acid. Sulphuric Acid reacts with water to form hydrates with distinct properties.The system consists of : Dilution Chamber with accessories -Glass. Heat Exchanger – Glass. Glass Buffer as Receiver & Circulation of dilute acid (Optional). Dilute Sulphuric Acid Circulation Pump (Optional). Glass Pipelines, Valves, & Fittings and Thermo well. Non – Return Valve for Acid & Water Inlet. Expansion Bellows In PTFE for all Nozzles of Glass Components. Features : Fully customizable Easy to install Corrosion resistant Continuous method of producing the broad range of Sulphuric Acid grades (Dilute Sulphuric Acid from 98% to 10% ~ 15%) The all Glass & PTFE construction of plant eliminates the material corrosion and allows this profitable operation to take place safely. The unit can be offered vertical or horizontal as per site layout. Compact design. The equipment is simple and easy to operate. Control outlet acid temperature 6. Design temperature: 160° C

Certification : CE Certified

Voltage : 380V

Power : 3-6kw

Warranty : 1 Year

...more

Solid Liquid Extraction Plant

We are one of the trusted companies in India, which is manufacturer and exporter of Solid Liquid Extraction Unit. The unit we provide is based on latest technology, which is mechanically designed and tested by our engineers so that it can give the best of its performance. Our unit is fully customized to meet our client’s requirement.Process Description :This operation involves preferential solubilising of one or more soluble constituents (solutes) of a solid mixture by a liquid solvent. The unit described here is for a semi-batch operation. The solid to be extracted is put inside a glass fibre bag and placed in an extraction vessel. Solvent from the reboiler is continuously evaporated, condensed and circulated through a reflux divider by means of piping network and valves.When desired/ steady concentration of solute is achieved in the solution the operation is discontinued. The solution is drained off and collected for further use. After charging fresh solid in fibre bag and solvent in reboiler, the cycle can be restarted again.The units are available in vessel sizes of 10, 20, & 50 Ltr and are suitable for operation under atmospheric pressure.Features : Easy maintenance Sturdy structure Fine functionality

Type : Automatic

Certification : CE Certified

Application : Industrial

Voltage : 220V

Power : 5-10kw

Warranty : 1 Year

...more

Simple Distillation Unit

Description : It consists of a vessel mounted in a heating bath and fitted with a condenser for condensing the fumes. receiver with drain valve can be added for receiving the condensate. The units are available in vessel sizes of 20, 50, 100, 200 & 300 Ltr. and is suitable for operation under atmospheric pressure and full vacuum.

Application : Chemical,Pharma Industries

Capacity : Upto 200 L

Power Source : Electrical

Warranty : 1 Year

...more

Shell & Tube Heat Exchanger

We are one of the trusted companies in India, which is manufacturer and exporter of Shell and Tube Heat Exchanger, Glass Shell and Tube Heat Exchanger. The system we provide is based on latest technology, which is mechanically designed and tested by our engineers so that it can give the best of its performance. Our system is fully customized to meet our client’s requirement. K-JHIL’s Shell and Tube Heat Exchanger is ideal for solo use as well as installation in various machines due to its optimum heat transfer efficiency.Key Features : Unmatched performance Negligible maintenance Longer operational life Less power consumption

Size : Standard

Application : Industrial

Type : Automatic

Material : Stainless Steel

Shape : Cylindrical

Voltage : 220V

Finishing : Polished

...more

Semi Automatic Gold Refining Machine

K-JHIL’s Semi-Automatic Gold Refining System is designed with specially designed control panel where each operation is done by operating buttons manually. The only difference between automatic and semi-automatic is that you have to operate switch manually for each step.Features :Control Panel Equipped With Switches For : Acid Charging System Scrubbing System Precipitation Transfer system Temperature control

Power Source : Electric

Certification : CE Certified

Voltage : 220V

Type : Semi Automatic

Warranty : 1 Year

Country of Origin : India

Application : Gold Refining

...more

Reflux Distillation Unit

Description : This is a versatile unit and can be used as Reaction Distillation Unit, Fractional Distillation Unit or a combination of both. All features of Reaction Distillation Unit and Fractional Distillation Unit are incorporated. The units are available in vessel sizes of 20, 50, 100 & 200L, and 300Ltr. is suitable for operation under atmospheric pressure and full vacuum.

Type : Reflux

Certification : CE Certified

Application : Chemical,Pharma Industries

Capacity : 20, 50, 100 & 200L, and 300Ltr

Power : 7.5 Hp

...more

Reagent Bottles

Material : Glass

Application : Storing Liquid

Color : Transparent

Cap Type : Screw Cap

Transparancy : 100%

...more

Reaction Distillation Unit

Description : This unit is used for carrying out reactions under stirred condition and with provision for simple reflux distillation. The reaction vessel is mounted in a heating bath and fitted with addition vessel, motor-driven stirrer and provision for condensation with refluxing. The product is sub-cooled and collected in a receiver. The units are available in vessel sizes of 20, 50, 100 & 200 & 300Ltr is suitable for operation under atmospheric pressure and full vacuum.

Application : Chemical, Pharma, etc.

Capacity : 50 - 200 L

Power : 7.5 Hp

...more

Quartz Reaction Tubes

Highly acclaimed for its abrasion resistance, robust design and long life, this Quartz Reaction Tube is manufactured using best quality materials under the guidance of our team of deft professionals. Widely demanded for chemical, petrochemical and other allied industry, this tube is extensively used for sealed tube reactions at high temperatures. Prior to dispatch, this quartz tube is well checked on various stern parameters to ensure a defect free range is delivered.

Size : Standard

Type : Solid

Material : Quartz

Thickness : 5-10mm

Application : Industrial

Color : Transparent

...more

Precious Metal Refining System

At K-JHIL we specially design and engineer system for Platinum Group Metal (PGM) as per client’s requirement and convenience. Contact us for more details.

Size : Customised

Type : Automatic

Certification : ISI Certified

Country of Origin : India

...more

Pilot Plant

Type : Customised

Material : Stainless Steel,Mild Steel

Application : Industrial

Voltage : 230 - 280 V

Power : Electric

Warranty : 1 Year

...more

Oil Distillation Plant

Type : Automatic

Certification : CE Certified

Voltage : 220V

Power : 1-5kw

Driven Type : Electric

Warranty : 1 Year

...more

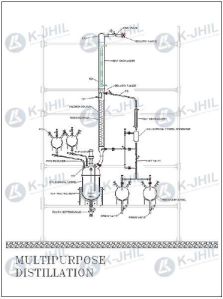

Multi Purpose Distillation Unit

We are one of the trusted companies in India, which is manufacturer and exporter of Multi Purpose Distillation Unit. The system we provide is based on latest technology, which is mechanically designed and tested by our engineers so that it can give the best of its performance. Our system is fully customized to meet our client’s requirement.K-JHIL’s Multi Purpose Distillation Unit can be used for separation of Azeotropic mixture using distillation methods such as Extractive distillation, Heterogeneous Azeotropic distillation, Distillation using ionic salts, Pressure-swing distillation, Reactive distillation and many other processes.Features : Compact multipurpose process pilot plant for R & D. Pharma, Fine chemicals. Heating and cooling system for Reactors.Max temp.200c.- Design for Distillation, Reaction, Absorption, Rectification and Extraction. Glass equipment’s Column available from 15mm to 450mm. Heat treatment annealed glass components. Heat Exchanger, Coil type, All Glass Shell & Tube Heat Exchanger. PTFE Agitator stirred assembly with magnetic coupling design according to your application. Explosion Proof 3 Phase Geared Motor with speed control Variable Frequency Drive. Unit working under high vacuum 1m bar. Available 2Ltr to 100ltr. Supporting Frame available in SS 304/316 with tubes and coupling, Nut bolts. Maximum Working Temperature 200°C.

Voltage : 220V

Power : 1-5kw

Driven Type : Electric

Warranty : 1 Year

...more

Liquid Extraction Plant

We are one of the trusted companies in India, which is manufacturer and exporter of Liquid Liquid Extraction unit. The unit we provide is based on latest technology, which is mechanically designed and tested by our engineers so that it can give the best of its performance. Our unit is fully customized to meet our client’s requirement.Features : Easy maintenance Sturdy structure Fine functionality Liquid extraction, sometimes called solvent extraction, is the separation of constituents of a liquid solution by contacting with another insoluble liquid. The unit described here is for a semi-batch operation.Process Description :The liquid to be extracted is poured into an extraction vessel. Solvent is boiled in a reboiler vessel and condensed in an overhead condenser, the pipework to the extraction vessel. The pipework incorporates valves in order that the solvent can enter the extraction vessel at either the base or the top, depending on the relative densities of the solvent and liquid to be extracted.The solvent and the extracted liquid pass back to the reboiler and the process is repeated until the extraction is complete. The extraction vessel is then drained and the solvent evaporated from the reboiler vessel and collected in the extraction vessel enabling the two liquids to be drained form their respective vessels.The units are available in vessel sizes of 10, 20, & 50 Ltr. and are suitable for operation under atmospheric pressure.

Type : Automatic

Voltage : 220V

...more

Jacketed Vessel

Type : Jacketed

Material : Metal, Glass

Shape : Round

Certification : CE Certified

Application : Industrial

Capacity : 100-1000ltr

Surface Finishing : Polished

Warranty : 1 Year

...more

Jacketed Glass Reactor

Type : Jacketed

Voltage : 220 V

Warranty : 1 Year

After-Sales Service Provided : Spare Parts

...more

Herbal Extraction Plant

Type : Automatic

Certification : CE Certified

Application : Herbal Extraction

Voltage : 440V

Power : 5-10kw

Driven Type : Electric

Warranty : 1 Year

...more

HCL Gas Absorber

Specifications : HCL absorption columns are used for absorption of Hydrochloric gas, which statutorily are not permitted to vent into the atmosphere, and to produce the HCl acid. The column is constructed with a series of packed sections, a gas introduction point below that, a condenser on the top, and a cooler at the bottom. Make water is sprayed from the top and acid is collected from the bottom. HCL absorption columns are available in 80DN to 300DN diameter (for the gas rate 10 Kgs/hr to 300 Kgs/hr approx). HCl gas can be economically absorbed forming Hydrochloric acid of 30% (w/w) concentration which can be re-used in the main process. Thus this absorption is a pollution abatement as well as a recovery process. The absorption can be done by two different methods : Adiabatic Absorption: This method is suitable when the inerts like air, phenolic compounds etc are substantial. Isothermal Absorption: This method is suitable when inerts like air phenolic compounds, etc ar negligible.

Type : Automatic

Application : Industrial

Material : Stainless Steel

...more

Falling Film Gas Absorber

Hydrogen Chloride gas is produced from the variety of process industries & mainly from chlorination operation. This must be scrubbed before venting to the atmosphere. Hydrogen chloride has great affinity of water and easily absorbed in water. The absorption of Hydrogen Chloride gas in to water cause large amount of heat, which has to be removed by means of suitable device.The falling film absorber is the simplest form of HCL absorber, HCL Gas Absorber which can be operated continuously. Falling Film Absorber is a vertically mounted shell and tube heat exchanger. The standard configuration of the falling film absorber consists of a suitable shell and tube heat exchanger with the necessary drain outlet for the acid. The Hydrogen Chloride Gas enters at the top of the absorber and flows concurrently with water/Dilute HCL.Process Description :Cooling Water is circulated through shell side of the Falling Film absorber to absorb the heat generated by the dilution of Hydrochloric acid gas with water. Due to its unique design and construction, the heat of absorption is efficiently removed at the zone of absorption, thereby making the absorber extra efficient. Thus the higher concentration of acid is produced due to low absorbing temperature.Capacity Range : 10Kg/hr. to 900 Kg/hr.Available up to 600mm dia.Salient Features : High absorption efficiency. High acid concentration achievable. Low outlet temperature. Easy operation and maintenance. Safe Operation due to low isothermal temperature. Handle a wide range of gas loading with minimum liquid flow rates to maintain full tube wetting. All the wetted parts of the falling film absorber are corrosion resistant to all the aggressive gases even at elevated temperatures. Variation in Hydrogen Chloride Gas flow rates or Composition causes no operation problem.

Type : Falling Film

Material : Metal, Rubber, Glass

Application : Industrial

Color : Transparent

...more

HCL Concentration & Recovery Plant

This is achieved by addition of a third ingredient, the extractive agent, which displays strong hygroscopic properties. Conc. HCL Concentration Plant, HCL & HCL gas is produced at the head of the extractive rectification column upon choice of an appropriate extraction agent. In the column the extraction agent is diluted with water, which is extracted in a selective fashion from the inflowing mixture.Subsequently, the extractive agent is recycled and newly fed into the extractive rectification process. Sulphuric acid and aqueous solutions of CaCl2 are appropriate extraction agents for the concentration of hydrochloric acid.As mentioned this is an economical technology the Azeotropic point is suppressed as best as possible which increases the relative volatility of HCL. The relative volatility may be impacted by change of the activity coefficients. This is achieved by addition of a third ingredient, the extractive agent, which displays strong hygroscopic properties. Conc. HCL & HCL gas is produced at the head of the extractive rectification column upon choice of an appropriate extraction agent. In the column the extraction agent is diluted with water, which is extracted in a selective fashion from the inflowing mixture. Subsequently, the extractive agent is recycled and newly fed into the extractive rectification process.Sulphuric acid and aqueous solutions of CaCl2 are appropriate extraction agents for the concentration of hydrochloric acid.

Type : Automatic

Certification : CE Certified

Application : Industrial

Feature : 220V

Power : 1-3kw

Driven Type : Electric

Warranty : 1 Year

...more

Glass Vessel Reactor

We are one of the trusted companies in India, which is Glass Reactors Manufacturer and exporter of Glass Reactors. The system we provide is based on latest technology, which is mechanically designed and tested by our engineers so that it can give the best of its performance. Our system is fully customized to meet our client’s requirement.Glass reactors – mixing vessels are frequently used for stirring, dissolving, mixing, extraction and other processes in kilo-lab and pilot plants. Jacketed models permit heat exchange for better dissolving and crystallization. Mobile mixing vessels can be transported with their content for further processing. They can also be equipped with condensers for vacuum distillation.Features : Full glass vessel with bottom valve Glass dome with ports for inlet, solid feed, vacuum, etc. PTFE coated stirrer, dry-running mechanical seal Magnetic stirrer drive, variable Frequency Drive to control speed RPM Mobile stainless steel frame

Voltage : 220 V

Type : Automatic

Warranty : 1 Year

After-Sales Service Provided : Spare Parts

...moreBe first to Rate

Rate ThisOpening Hours