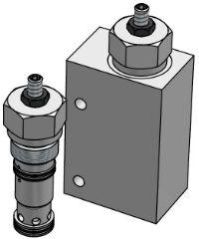

Unloading Valve

Unloading valves are used to unload the pump to tank when the pressure in a separate part of the circuit reaches a pre-set level. The most common application is to maintain pressure in an accumulator which may be used in an emergency to operate an essential hydraulic function.

...more

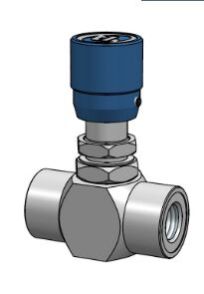

Throttle Valve

Throttle valves can be used where volume flows have to be infinitely controlled in both directions without taking pressure fluctuations into account. The line mounted design with BSP ports is ideal for installing in-line for power packs or hydraulics circuits.

...more

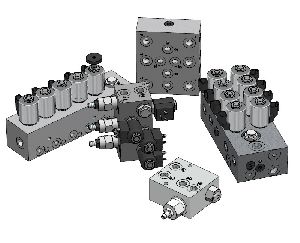

Safety Blocks

pressure valve

The modular or sandwich valve is stacked along with directional valves in CETOP 3 interfaces to provide a reducing valve system in various ports depending on the configuration. The valve can be used to either reduce pressure in the main pressure port ‘P’ or the actuator ports ‘A’ or ‘B’.

...more

Pressure Control Valve

The modular or sandwich valve is stacked along with directional valves in CETOP 3 interfaces to provide a reducing valve system in various ports depending on the configuration. The valve can be used to either reduce pressure in the main pressure port ‘P’ or the actuator ports ‘A’ or ‘B’.

...more

Poppet Valve

Solenoid Poppet Valves are extremely versatile. They can be used in various systems and are flexible in their mounting capabilities. Typical usage includes the control of actuators in a hydraulic system, decompression of hydraulic fluid in heavy cylinders, On-Off systems, Pilot Valves, etc.

...more

pilot check valves

Pilot check valves allow flow to pass in one direction, with a low pressure drop, then prevent reverse flow until pilot pressure is applied. There are many applications for this valve type, the most common being to lock and hold a cylinder, or another hydraulic actuator, in position. The CK35 is a small cartridge valve and is ideally suited for fitting directly into a cylinder, giving economy of installation, direct control of cylinder movement and ease of servicing.

...more

nylon sleeve gear coupling

Nylon couplings are compact and can operate over a wide temperature range at speeds up to 5,000 RPM and are effectively used in applications such as Motor Generator sets, pump sets, and many lightAtoAmedium duty industrial coupling applications. The resilient nature of the nylon material makes the contact of the hubs and sleeves almost frictionless. Since no lubrication is used, the coupling can readily be adapted to many applications including vertical and blind installations where the slipA together components offer easy inspection and adjustment. The smooth and hard surface (crystalline structure) and the high thermal stability and resistance to lubricants, fuels, hydraulic fluids, dissolvents etc. make polyamide an ideal material for components stressed by sliding, particularly for the coupling production.

...more

nylon gear

Nylon couplings are compact and can operate over a wide temperature range at speeds up to 5,000 RPM and are effectively used in applications such as Motor Generator sets, pump sets, and many lightAtoAmedium duty industrial coupling applications. The resilient nature of the nylon material makes the contact of the hubs and sleeves almost frictionless. Since no lubrication is used, the coupling can readily be adapted to many applications including vertical and blind installations where the slipA together components offer easy inspection and adjustment. The smooth and hard surface (crystalline structure) and the high thermal stability and resistance to lubricants, fuels, hydraulic fluids, dissolvents etc. make polyamide an ideal material for components stressed by sliding, particularly for the coupling production.

...more

Mobile Hydraulic Systems

Hydraulic Systems for Mobile Applications include Hydraulic Integrated Circuits (HICs) for Excavators, Diggers, Front End Loaders, Wheeled Cranes, Track Cranes, Slew Cranes, Forklifts, Telehandlers, Tipper Trucks, Tuck Mounted Cranes, Backhoe Loaders, Rock Drills, Well Drills, Side Dump Loaders, Road Milling Machines, Cement Pumps, Transit Mixers, Paving Machines, Crushers and Screeners, Mining Equipments, Agricultural Sprayers, Harvesters, Combines, Crop Sprayers and a vast number of other equipement. Features HICs have a variety of benefits ranging from a more compact system envelope and light weight to reduced leakage points, ease of servicing and reduced power usage. Solenoid Valves with Deutch Moulded connectors and minimum cycle life of 1,000,000 cycles are used to reduce servicing and downtime. Only cartridges that are forgiving to ingress of particles are used. Stainless steel cartridges can be made available on request.

...more

mini mess systems

Industrial Hydraulic Systems

Hydraulic Systems for Industrial applications include Hydraulic Integrated Circuits (HICs) for Industrial Presses, Baling Presses, Leather Manufacturing Machines, Injection and Blow Moulding Machines, Machine Tools, Press Brakes etc. Features HICs have a variety of benefits ranging from a more compact system envelope and light weight to reduced leakage points, ease of servicing and reduced power usage.

...more

Hydraulic Valves

Lift Lower blocks are a compact hydraulic solution to control single acting cylinders that are generally mounted on stackers and scissor lifts. They offer a complete solution for lifting, controlled lowering and safety of the pump, cylinder and personnel.

...more

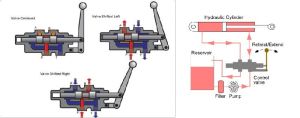

Hydraulic Spool Valve

Unloading valves are used to unload the pump to tank when the pressure in a separate part of the circuit reaches a pre-set level. The most common application is to maintain pressure in an accumulator which may be used in an emergency to operate an essential hydraulic function.

...more

Hydraulic Solenoid Valve

Typical usage includes the control of actuators in a hydraulic system, decompression of hydraulic fluid in heavy cylinders etc.

...more

Hydraulic Solenoid

N.C. De-energised or N.O Energised: 2 to 1 – full flow, pressure difference through the pilot orifice holds the main poppet open. 1 to 2 – restricted flow, main poppet seated due to pressure differential. N.C. Energised or N.O De-energised: 2 to 1 – No flow, pilot orifice closed, main poppet seated due to pressure differential. 1 to 2 – full flow when the solenoid force is overcome.

...more

hydraulic relief valve

Pressure Relief valves are used to limit the pressure in the system as set on the valve. Direct Relief Valves are applicable in systems where quick pressure release is of prime concern for safety. This is an economical solution for systems having small flows. The valve is a zero leak valve due to the metal sealing of the poppet on the seat. The DR06 can also be used for pilot systems.

...more

Hydraulic Directional Control Valve

Throttle valves can be used where volume flows have to be infinitely controlled in both directions without taking pressure fluctuations into account. The screwed cartridge design is ideal for installing in manifold blocks or in CETOP sandwich plates

...more

Hydraulic Check Valves

These cartridge check valves allow unidirectional flow at a low pressure drop. They fit into machined cavities and are therefore perfect for installation into custom made hydraulic circuits, manifold blocks or other hydraulic equipment for load sense or low flow applications.

...more

Hydraulic Cartridge Valve

When the pump is switched on, the oil from the pump extends the cylinder. After full extension, the Check Valve (1) holds the load in place at which point the pump can be switched off. To lower the valve, the Solenoid Valve (3) is energized which opens the flow of oil to tank. The rate of lowering is adjusted by means of a Flow Control Valve (3). There is an inbuilt Relief Valve (4) for pump protection in case of a rise in pressure.

...more

Direction Control Valve

Directional spool valves type WE22 (electrically operated) are intended for change in direction of fluid flow in a hydraulic system and thus it allows to change direction of movement of a receiver - mostly piston rod of a cylinder or hydraulic motor as well to use functions: on and off. These directional spool valves are used for subplate mounting in any position in a hydraulic system.

...more

counterbalance valves

Counterbalance valves give static and dynamic control of loads by regulating flows in or out of hydraulic actuators. They prevent load runaway or allow for thermal expansion of the hydraulic fluid in the system. They can also be used to develop back pressure in applications such as plastic moulding to improve the colour quality of the polymer mix.

...more

Compact Relief Subplate NG6

The MBR03 subplate is a CETOP3 manifold with an inbuilt relief valve to limits system pressure by directing flow from the P to T Port when pump pressure reaches the valve setting. It reduces the need for an additional relief valve when using CETOP3 modular stacking valve. Features CETOP3 interface provides sandwiched stacking for directional control valves and other modular valves. Mating surfaces are ground and ports with OE rings are spot faced. The valve pressure setting is adjustable by means of an adjusting knob and locknut.

...more

cartridge valve

Cartridge valves are used to limit the pressure in the system as set on the valve. Direct Relief Valves are applicable in systems where quick pressure release is of prime concern for safety. This is an economical solution for systems having small flows. The valve is a zero leak valve due to the metal sealing of the poppet on the seat. The DR06 can also be used for pilot systems.

...more

hydraulic control valve

Counterbalance valves give static and dynamic control of loads by regulating flows in or out of hydraulic actuators. They prevent load runaway or allow for thermal expansion of the hydraulic fluid in the system. They can also be used to develop back pressure in applications such as plastic moulding to improve the colour quality of the polymer mix.

...moreBe first to Rate

Rate ThisOpening Hours