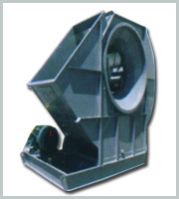

Hopper Auto Loader

Get Price Quote

For conveying of plastic granules from bin to hopper of plastic processing machines. Reduces wastage of granules, reduces labour casts, reduces handling times, improves productivity. Features : Noiseless operations No leakage Less and easy maintenance Material wastage reduced No wear and tear No Compressed air requirement High efficiency and reliablity Labor costs reduced Principle of Working : The Auto-loader ensures that the hopper is always full. The ladder stops loading material once the hopper is full and automatically restarts the loading as soon as the material level inside the hopper falls. The turbine blower exhausts air from the receiver creating a vacuum. Due to the vacuum, material from the bin rises via the flexible pipe connecting the receiver to the material suction probe ( the probe remains partly submerged in the bin containing resins/ materials). An efficient filter between, filters the air to remove 'fines' and dust of the resin. The loading time is controlled by the timer on the panel. The material is unloaded from the receiver into the hopper via a flapper gate which opens under the weight of the material. Once the material is unloaded into the hopper and receiver is empty, the flapper gate closes and the cycle of suction of the material from the bin restarts a gain with 3-5 seconds delay.

Hopper Auto Loader

Get Price Quote

Industrial process need production by loading the M/C and process at reuired speed and eifficency by loading the row material and production product without human inpervention of partial dependance need auto loader for hoper feed system

Best Deals from Auto Loader