Gun Metal Casting

480 Per Kilogram

we are doing all type of gun metal casting

Gravity die casting

Get Price Quote

60 T HMT- BUHLER COLD CHAMBER DIECASTING MACHINE. 180 T HMT COLD CHAMBER DIECASTING MACHINE 250 T WEINGARTEN COLD CHAMBER DIE CASTING MACHINE. H-400 D HMT COLD CHAMBER DIE CASTING MACHINE. FULLY EQUIPPED GRAVITY DIE CASTING SETUP.

Looking for Industrial Casting Service Providers

Aluminium Gravity Die Casting

Get Price Quote

The gravity process begins by preheating the mold to 150-200 °C (300-400 °F) to ease the flow and reduce thermal damage to the casting. The mold cavity is then coated with a refractory material or a mold wash, which prevents the casting from sticking to the mold and prolongs the mold life. Any sand or metal cores are then installed and the mold is clamped shut. Molten metal is then poured into the mold. Soon after solidification the mold is opened and the casting removed to reduce chances of hot tears. The process is then started all over again, but preheating is not required because the heat from the previous casting is adequate and the refractory coating should last several castings. Because this process is usually carried out on large production run work-pieces automated equipment is used to coat the mold, pour the metal, and remove the casting. Maximum Weight of Single Component in Gravity Die Casting possible is 35kg.

Non Ferrous Metal Casting

Get Price Quote

Non Ferrous Metal Casting, Gun Metal, ferrous metal alloy, Sand Casting

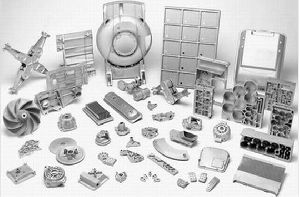

Metal Castings

Get Price Quote

aluminum kitchen utensils, aluminium wall hanger, aluminium chakla

Aluminium Gravity Die Casting

Get Price Quote

non ferrous sand casting components

Gravity die casting

Get Price Quote

aluminium casting service, Zinc Castings, Gunmetal Castings

Gravity die casting

Get Price Quote

Aluminium Castings, Dies, mould

die casting services

Get Price Quote

Aluminium Cast Alloy, casting alloy

Metal Casting

Get Price Quote

Metal Casting, alloy castings, alloys casting, Gum, lead casting