Oil Separator

500,000 - 800,000 Per Set

01 Piece(s) (MOQ)

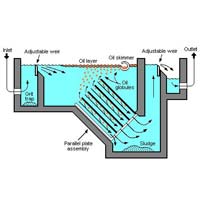

The Coalescing Plate Interceptor employs a series of plate packs inclined at opposite angles in close proximity; the most effective technique for increasing setting area per unit volume. As a result, CPI Separators requires far less space than settling tanks. The units can be offered in fully certified pressure vessels, or atmospheric tanks. Process Technology Waste water enters the inlet nozzle into an enlarged coalescing section. This coalescing section is where heavier solids and sludge settle out of the waste water to the bottom of the vessel where it is discharged through the clean out nozzle. Waste water then flows through the perforated distribution baffle plate. After it is evenly dispersed, it flows down through the plate pack where oil rises to the top of the corrugations and coalesces with other oil droplets. The large oil droplets rise up through the plate pack to the oil/water interface. Coalesced oil will flow over an internally adjustable oil weir and is removed through the oil outlet nozzle. Light solids and sludge separation is simultaneously accomplished within the pack by settling to the bottom of the corrugations where solids are directed to the sludge drain. The flow out of the plate pack travels upward and spills over a fixed water weir, then exits the vessel through the water outlet nozzle for further downstream treatment or disposal. Our CPI Separators effectively remove oil droplets of 50 microns or larger, depending on fluid properties. Applications Oilfield production onshore and offshore Refineries Petrochemical Plants Industrial Plants Rainwater runoff Water treatment facilities

Turbo Separator

Get Price Quote

Principle : The equipment consists of a conical shaped body fabricated from MS plate and internally cladded with SS 304 one operating door. The door is provided with one light rejects. A tangential inlet nozzle is given on the main body for the pulp inflow. In accept chamber is attached to the main body for the collection of accepted pulp. This chamber is provided with a nozzle at the top for getting the accepted pulp and another nozzle at the bottom for cleaning purpose. In between the accepted chamber and main body a screen made from SS 304 material is provided. The overall functioning of the equipment is done by a SS 410 / CA 40 casted rotor. The accept is collected in the accept chamber whereas the light rejects are taken in the secondary screen for fibre recovery. The shaft is mounted on 2 bearings in a CI bearing housing. A stuffing box arrangement having GM bushes and gland is provided for the proper guiding and sealing of the shaft. The equipment is driven by an electric motor through flat belt pulley. Features : Operating consistency at 2-3% Light and heavy impurities are separated and efficiently removed. Due to high deflaking action the screen is ideally suited to kraft and other type of furnish. Easy maintenance and minimum fiber loss. The body is made out of M.S. with S.S. Cladding, Special model is also available in S.S. 316 sandwich plate (S.S. and M.S.) with base frame and stifners in M.S.

Best Deals from Separation Equipment

Oil Skimmer

Get Price Quote

An oil skimmer is a machine that separates a liquid from particles floating on it or from another liquid. A common application is removing oil floating on water. VEPL make oil skimmer is an effective means of removing oil from water and water-base solutions. Often, skimming by itself will reduce oil to an acceptable level of water purity. Depending on the characteristics of the liquid, we recommend the belt type oil skimmer. The unit can be used as a pretreatment before filtration, and in conjunction with a coalescing system. Oil skimming makes use of the differences in specific gravity and surface tension between oil and water. These physical characteristics allow the belts to attract oil and other hydrocarbon liquids from the surface of the fluid. Oil Skimmers are simple, dependable and effective tools for removing oil, grease and other hydrocarbons from water and collants. Often, an oil skimmer by itsel can achieve the desired level of water purity. In more demanding situations, oil skimming is a cost-effective menas of removing most of the oil before using more complicated and costly treatments such as coalescers, membrane filters and chemical processes. Features Easy to deploy. Simple service and maintenance. Can be used to feed oily water separator. Skims in all directions. No operators required. No flame proofing required. No electrical safety concerns. No safety guards. Equally effective with all oil types. Fast oil removal flow rates. Applications Waste Water Sump. Sewage Sump. Parts Washers. Coolant System. Autimobile. Heat Treating Fluids. Hotel and Food Processing Units Refineries. Advantages Required less space. A single unit elevates and separates oil. Lifts oil any distance without the need of expensive pumps. Maintains skimming efficiency with fluctuating fluid level. Can be used in depths as shallow as one foot, or as deep as 100 feet. Requires no tank modifications in most applications. Operates in turbulent liquid using optional tail pulley cage and tether assembly. Easy mounting and fast cleaning, with minimal maintenance. Inverter control drive for precise operation control and safety. Minimum maintenance.

Vibro Sifter

Get Price Quote

We provide a wide range of high efficiency Vibro Sifter that is highly appreciated in the national and international markets. To meet the different requirements of the clients, our Vibro Sifter Machine is available in various models. Precisely designed to perfection, our Vibro Sifter Machine is high in performance and low in maintenance. Today, we are well reckoned as one of the prime Industrial Vibro Sifter Manufacturers and Suppliers based in India. Product Description of Vibro Sifter Grading matrial of ganules to fine power Model : 13", 20", 30", 48", & 60" Available STD / CGMP / R & D Model

Vibro Sifter

Get Price Quote

Each product in our range is made using reliable materials procured from leading vendors. Thus, our products are trustworthy. Leveraging on our experience, we, as a supplier of vibro sifter have placed ourselves in the upper echelons of the industry.

Ss Vibro Sifter

Get Price Quote

We are offering ss vibro sifter. We have a wide range of s.s vibrosifter to suit industrial requirements, various sizes and designs to suit specific customer needs. Many of the products are available in ready stock for instant delivery commitments or can be delivered on short notice.

Vibro Sifter

Get Price Quote

We provide a wide range of high efficiency Vibro Sifter that is highly appreciated in the national and international markets. To meet the different requirements of the clients, our Vibro Sifter Machine is available in various models. Precisely designed to perfection, our Vibro Sifter Machine is high in performance and low in maintenance. Today, we are well reckoned as one of the prime Industrial Vibro Sifter Manufacturers and Suppliers based in India. Product Description of Vibro Sifter Grading matrial of ganules to fine powerModel : 13", 20", 30", 48", & 60"Available STD / CGMP / R & D Model

Vibro Sifter Machine

250,000 Per unit

Moisture Separator

Get Price Quote

We manufacture a wide assortment of indoor air filtration systems and industrial air filtration systems like air moisture separator, steam moisture separator, industrial moisture separator, etc., that are fabricated using high quality raw material and are used to for the filtration of air. Applicable in various industries, these moisture separators can be customized to suit the specific requirements of our clients.

Stainless Steel Vibro Shifter

Get Price Quote

Stainless Steel Vibro Shifter is used for grading of materials according to the particle size, and for separating mass compositions of liquid and solid. Stainless Steel Vibro Shifter consists of a specially designed device mounted vertically at the center of the base plate of the screen. Stainless Steel Vibro Shifter is used in pharmaceuticals industry, and offers dust free operation. Multi deck models of Stainless Steel Vibro Shifter are also available with us.Features : Simple and compact construction Springs enable faster separation Offers less maintenance and power construction

Oil Water Separator

500,000 Per Number

Turbo Separator

Get Price Quote

Turbo Separator, ATS Pulper, Head Box, heavy duty press, Pope Reel

Cyclone Seperator

Get Price Quote

We are leading best cyclone seperator supplying company.

Air Oil Separator

Get Price Quote

We cater the finest quality Air Oil Separator in the marketplace. The combination of Borosilicate Glass Fiber and Synthetic Media are used in Air Compressor Oil Separator for separating the oil from the air. These separators are endurable and long lasting in nature. In addition to this, we are one of the chief Compressed Air Oil Separator Suppliers in the country.

Turbo Sifter

Get Price Quote

Turbo Sifter, Rapid Mixer & Wet Granulator, Vacuum Transfer Device

Air Oil Separator

Get Price Quote

Air Oil Separator, Air Oil Filters, Cylinder Liner, Crankshaft

belt oil skimmer

Get Price Quote

belt oil skimmer, Oil & Grease Trap, Effluent Treatment Plants

Stainless Steel Vibro Sifter

Get Price Quote

Stainless Steel Vibro Sifter, Pharmaceutical Machinery

Centrifugal Oil Separator

Get Price Quote

Centrifugal Oil Separator