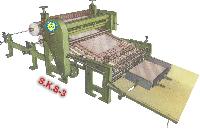

Reel to Sheet Cutting Machine

230,000 Per Set

01 Piece(s) (MOQ)

We are offering reel to sheet cutting machine. This machine is also designed for high production and accurate cutting of sheets or 2ply corrugated board without damaging flutes and liner paper with the help of automatic jogging attachment and gear operated.

decatising machine

1,250,000 Per Piece

1 Piece (MOQ)

Features: · Cooling is made possible while drawing off. · Pre-determined adjustable cycles. · Shortest Decatising time. · Increased stability and high smoothness. Salient Features: The machine is provided with : · Two main stainless steel perforated cylinders of 600 mm. / 800 mm dia. fabricated out of 316L stainless steel perforated plates mounted on ball bearings fitted with nozzles to avoid condensation · An extra stainless steel cylinder of 300 mm. dia. for drying the wrapper. This cylinder has a temperature Controller to control steam and to avoid damage to the wrapper. · Two M.S. hard-chrome plated rolls with both the cylinders, to keep the marks fully pressed without creasing, while feeding it to the main cylinders. Pneumatic cylinders are provided to adjust the pressure and tension of the fabric. · One suitable roll with feeler switch to maintain properly the center of the wrapper. · Plating down arrangement, with gear motor and for picking the fabric without tension. · A 5 H.P. A.C. Electric Motor (for main cylinders) with pneumatic torque clutch and brake, for easy control of wrapper tension and uniform surface speed. · We also have HYDRAULIC MAIN DRIVE system running the machine with hydraulic motors and power pack instead of clutch and gears which we have developed lastly. Outstanding Advantages: · Infinite wrapper tension control permits any desired even tension. · The pole-changer drives both cylinders simultaneously at all times. · Smooth and steady wrapper “take-up” obviates unequal strain and distortion. · An automatic timer eliminates the possibility of human error and guarantees similar operational cycles. · A 5 H.P. Vacuum pump ensures increasing output and improves the ‘finish’, as it cools the fabric after steaming. · Pneumatic pressing devices avoids crease on the fabric. · Time saving due to simultaneous loading and unloading of fabric. · Lower heat and energy consumptions.

Best Deals from Textile Processing Machinery

decatising machine

Get Price Quote

Decatising machine video links:- http://www.youtube.com/watch?v=_yn2hYmP2VM http://www.youtube.com/watch?v=Vk5brYgbj6g http://www.youtube.com/watch?v=tj3JKOzNpLw http://www.youtube.com/watch?v=BEtG6Vz7uqo Cooling is made possible while drawing off. Pre-determined adjustable cycles. Shortest Decatising time. Increased stability and high smoothness. Salient Features The machine is provided with : Two main stainless steel perforated cylinders of 600 mm. / 800 mm dia. fabricated out of 316L stainless steel perforated plates mounted on ball bearings fitted with nozzles to avoid condensation An extra stainless steel cylinder of 300 mm. dia. for drying the wrapper. This cylinder has a temperature Controller to control steam and to avoid damage to the wrapper. Two M.S. hard-chrome plated rolls with both the cylinders, to keep the marks fully pressed without creasing, while feeding it to the main cylinders. Pneumatic cylinders are provided to adjust the pressure and tension of the fabric. One suitable roll with feeler switch to maintain properly the center of the wrapper. Plating down arrangement, with gear motor and for picking the fabric without tension. A 5 H.P. A.C. Electric Motor (for main cylinders) with pneumatic torque clutch and brake, for easy control of wrapper tension and uniform surface speed. We also have HYDRAULIC MAIN DRIVE system running the machine with hydraulic motors and power pack instead of clutch and gears which we have developed latestly. Outstanding Advantages Infinite wrapper tension control permits any desired even tension. The pole-changer drives both cylinders simultaneously at all times. Smooth and steady wrapper “take-up” obviates unequal strain and distortion. An automatic timer eliminates the possibility of human error and guarantees similar operational cycles. A 5 H.P. Vacuum pump ensures increasing output and improves the ‘finish’, as it cools the fabric after steaming. Pneumatic pressing devices avoids crease on the fabric. Time saving due to simultaneous loading and unloading of fabric. Lower heat and energy consumptions.

Reel to Sheet Cutting Machine

Get Price Quote

We provide the clients reel to sheet cutting machine (sks 3) that is designed for high production and accurate cutting of sheets or 2ply corrugated board without damaging flutes and liner paper with the help of automatic jogging attachment. specifications model no. : sks - 3 bodythis strongly design machine can be used as an independent unit to a corrugation machine for direct and accurate sheet cutting by rubber roll.it reduces the percentage of wastage as a result to minimize with high production capacity. Setting actionit is gear operated for adjusting of sheets to the required length from 5” to 118” according to size chart.set of gears consisting 22 nos. Designthe machine is robust in design and in grade castingheavy metal ms pipe coated with natural rubber for rubber rollnylon sandwich belt shall be provided as a delivery conveyor to carry the sheets out.reel stand is provided to load the roll.pedestal made in china ucp 208 (nis etc).single phase, d/c electric motor 1440rpm / 440v isi marked, certified by iso 9001 – 2000.hammer tone finish (opal green, parrot green) in colour.control panel with digital counting attachment.all moving parts are protected by safety guards.jogging attachment is provided to collect the paper automatically technical data machine sizemotor (h.p)floor spacemachine heightgross weight (kg) approx.54"3.0100" x 85"60"1000-1250 kg64"3.0100" x 95"60"1200-1550 kg

Reel Optimization System

Get Price Quote

Solutions For Paper Industry Reel Optimizing System (ROS) Improves the reel quality and reduces the waste of paper caused by reel chandes 2-4% savings in paper. Eliminates bottom breaks, surface breaks and reduces turn-up breaks. Gentle control forces protect the machineryDisc Gap Control System: Keeps the disk gap constant in disc refiners even at considerable force variations Rider Roll System: Continuously sets the most efficient line pressure between the carrier rolls and the paper reel.

yarn heat setting machine

Get Price Quote

1 Piece(s) (MOQ)

decatising machine

Get Price Quote

unique finish effects, controllable with optimum steaming, vacuuming and wrapper cloth pressure. suitable for polyester/wollen, polyester/cotton or viscose blends, from light fabrics likes sarees/shirtings to as heavy as corduroy suitings. gentle wrapper transport with a.c. Inverter drive for main cylinders and efficient drying system to achieve long wrapper life. time saving due to simultaneous loading and unloading of fabric. lower heat and energy consumptions cylinders: two main cylinders fabricated out of s.s. 316 stainless steel perforated plates mounted on ball bearings with specially designed gun metal nozzles for effective steaming and cooling operations driven by a.c. Electric motor. dryer cylinder: one stainless steel dryer cylinder provided at the bottom between the two main cylinders having proper heat controlling arrangement to dry the wrapper. pressure rolls: two hardchromed pressure rolls to press the fabric while feeding it to the main cylinders to ensure crease free entry of the fabric into the machine. Pneumatic cylinders are provided to adjust the pressure and tension of the fabric. vacuum pump: 5 h.p. Hydrovaccum system to save the power and water or 15 h.p. Water ring tye vaccumpump for colling the fabric. control panel: electrical control panel complete with synchronous timers, solenoid valves, pressure gauges, thermometers, push buttons, tele tell bulbs and other safety devices including auto/manual selection switches. plaiting down arrangement: plaiting down arrangement with geared motor on either side for piling the fabrics. drive : a.c inverter drive or hydraulic drive or chain drive will be provided

decatising machine

Get Price Quote

Unique finish effects, controllable with optimum steaming, vacuuming and wrapper cloth pressure. Time saving due to simultaneous loading and unloading of fabric. Lower heat and energy consumptions.

sulzer loom machine

Get Price Quote

sulzer loom machine, textile heavy machinery, Weaving machine

fire hose loom machine

Get Price Quote

fire hose loom machine, Liquid Syrup Making Plant

textile needle looms

Get Price Quote

textile needle looms, stainless steel needle looms

textile processing machine

Get Price Quote

YAMUNA is a widely prominent and popular name in the field of manufacturing and supplying varied collections of textile processing machine in India.

Wire Weaving Loom

Get Price Quote

Wire Weaving Loom, automatic wire crimping machine, PVC Wire Coating Plants

textile processing machine

Get Price Quote

textile processing machine, leather machinery

knife cutting machine

Get Price Quote

knife cutting machine, grooving machines, mechanical show cutter