Solid Carbide Reamer

As a dependable Supplier from Tamil Nadu(India), we ensure that our customers obtain only quality assured products. Our up-to-date logistic facilities support us in meeting the delivery deadlines promised to the customers.

...more

Single Pass Honing Tools

We are primarily engaged in manufacturing, supplying and exporting top-tier Single Pass Honing Tools across Indian and international markets. Unparalleled in quality, these Single Pass Honing Tools are contrived using quality-certified materials and ultramodern technology. To deliver them in unharmed state, we rely upon appropriate packaging and transportation mediums. Whether placing retail, bulk or bespoke order, we assure to quote best prices. Details : Single pass honing, also referred to as diamond bore sizing, is a good way to produce parts economically when the bore is small or has thin-walled members that need to be honed. Examples of such applications include torque convertor hubs, and a host of other through bores such as connecting rods where cross hatch pattern and super fine surface finish are not required. Single pass honing system is a new choice of technology in honing process an alternative to conventional honing for bore finishing.

...more

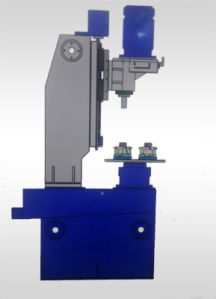

Single Pass Honing Machine

Single pass honing four spindle machine designed to meet the requirements of high production for components of bore dia upto 38 mm. Hence, two components can be finished every cycle. The productivity is doubled. Machine Design Features » CNC Servo controlled vertical axis. » High precision rotary index table. » Rigid, compact machine base. » Reduces Waste and Rework. » Reduces Tooling and Set Up Costs.

...more

Roller Burnishing Tools

Based in Tamil Nadu, we are associated in #1 league of Manufacturers, Exporters and Suppliers of Roller Burnishing Tools across the globe. Contrived using scoring burnishing technology and finest grade materials, these Roller Burnishing Tools have an acclaimed surface finish and dimensional preciseness. High on quality scales, these Roller Burnishing Tools are attainable from us in ample specifications. With us, stay assured of reasonable pricing.Details : Burnishing technology we produce roller-burnishing tools for burnishing internal diameters, external diameters, tapered holes shafts, radius and flat parts. Steel, cast iron, aluminum, bronze and all other metals of hardness up to 30 hrc can be easily and readily roller burnished. Our burnishing tools are attachable to lathes, boring machines, drills, NC machines and any rotating spindle machine where either the component or the tool can be rotated. Moreover, parts are interchangeable over a range of sizes and tools can be disassembled quickly to convert to new sizes or to replace wear parts. Roller Burnishing is a cold working process in which highly polished and hardened rollers roll over the surface and high peaks of the surface roughness cold flows into the cavities, thereby imparting smooth surface finish of the order of 0.05 µm ra and close dimensional tolerance. Id Multi-Roller Burnishing: Roller Burnishing is a chip less machining method which cold works the metal without cutting or abrading the surface. It removes no metal but rather compresses, or “irons-out” the peaks of a metal surface into the valleys, generating a dense and uniform surface. Main Applications : Pump electric motor and covers. Fuel injection pumps. Valves. Connecting rods. Cylinder blocks. Resistant to fatigue failure. Corrosion resistance. Features & Benefits: Accurate sizing. Fast cycle time. Eliminate secondary operations. Low production cost. Close dimensional tolerance. Fatigue & corrosion resistant surface. Smooth low micro-inch surface finish. Range of Roller Burnishing Tools : Internal & external burnishing tools Short & long series tools Single & multi rollers tools Taper & Special Profile Tools

...more

Od Diamond Burnishing Tools

We are counted among the reputed Manufacturers, Suppliers and Exporters of OD Diamond Burnishing Tools. The OD Diamond Burnishing Tools offered by us are manufactured in compliance with set industrial norms. Strict quality-tests based on different parameters ensure that only defect-free Brushing Tools reach the buyers. Bulk orders of the Tools are processed by us as per the specific requirements of the buyers.

...more

OD DIAMOND BURNISHING TOOL

OD DIAMOND BURNISHING TOOLrn This tool can be use for Hard material on OD. Can achieve good surface finish ,from 16mm to any size

...more

Machine Tools

Pournami Tools is a premium manufacturing company, the company has wide experience in machine tools like Twist drills, reamers, Milling cutters, Screwing Taps, Tools bits.

...more

ID Diamond Burnishing Tools

Based in Tamil Nadu, we have earned a good name for manufacturing, supplying and exporting top-tier ID Diamond Burnishing Tools across the world. Deeply appreciated for their excellent surface finish, accurate dimensions and durable life, these Id Diamond Burnishing Tools performs splendidly even on the hardest material. We offer them in any size range above 25mm. Further, these nominally priced Tools are attainable in bulk as well.

...more

Honing Tools

We offer a wide range of honing tools for multi-tasking machines, which is easy-to-use and effective for longer period of time. Our range of honing tools is manufactured using superior manufacturing technologies and excellent raw materials. In this way, our products exhibit properties such as durability and sturdiness. The honing process can deliver remarkable improvements in finished bore size, geometry and surface finish honing technology stands for superior precision, high reliability and considerable versatility. Advantages » Lower friction across the interior surface. » Has a positive impact on productivity, owing to smoother, faster inner surfaces. » Minimize surface roughness to negligible levels, Minimize wear and tear. » Ensures consistency of dimensions.

...more

Honing Tool

Honing ToolsrnWe offer a wide range of honing tools for multi-tasking machines, which is easy-to-use and effective for longer period of time. Our range of honing tools is manufactured using superior manufacturing technologies and excellent raw materials. In this way, our products exhibit properties such as durability and sturdiness.rnThe honing process can deliver remarkable improvements in finished bore size, geometry and surface finish honing technology stands for superior precision, high reliability and considerable versatility.rnAdvantagesrn» Lower friction across the interior surface.rn» Has a positive impact on productivity, owing to smoother, faster inner surfaces.rn» Minimize surface roughness to negligible levels, Minimize wear and tear.rn» Ensures consistency of dimensions.

...more

End Mill Cutter

Our company is reputed as trader in the industry and situated in the well-connected area of Tamil Nadu(India). Our warehouse is installed with advanced machines and all required amenities ensuring safe storage of diverse kinds of products requiring different storage temperatures and conditions.

...more

diamond burnishing tools

Roller Burnishing Tools: Roller burnishing is a cold working process in which highly polished and hardened rollers roll over the surface and high peaks of the surface roughness cold flows into the cavities, thereby imparting smooth surface finish of the order of 0.05 µm Ra and close dimensional tolerance.

...more

Deburring Tools

The Deburring Tools, doled out by us, are known to produce fine quality metal products within less time and cost. Developed using au courant techniques and rich resources, these Deburring Tools are durable, user-friendly and require low upkeep. Avail them from us in customized specifications at marginal prices. For bulk queries, contact us. We are the renowned Deburring Tools Manufacturer, Exporter and Supplier in India and abroad. Details : The Deburring Tools is designed for rugged use and comprises a simple arrangement of components that require negligible readjustment and handling. The tool works on the principle of spring tension and functions by holding the cutting blade in the extended position and causes it to deburr the front side of the hole.

...more

deburring tool

Deburring tool was developed as one of the most efficient and economical tools for mass production. The deburring tool is designed for rugged use and comprises a simple arrangement of components that require negligible readjustment and handling. The tool works on the principle of spring tension and functions by holding the cutting blade in the extended position and causes it to deburr the front side of the hole. Advantages : » The deburring tool requires no special skill set to operate and handle. » Deburring tool produce better – quality parts, with faster production, and at a lower cost.

...more

Camshaft

Owing to our rich industry experience, we have emerged as a renowned Manufacturer, Supplier and Exporter of Camshafts. The Camshafts we make available are known for their high corrosion resistance, durable design and impeccable quality. In order to meet the bulk and urgent requirements of the buyers, we maintain ab large stock of the Camshafts in our state-of-the-art warehouse. Buyers can obtain it at market-leading rates from us.

...more

burr off tool

The BURR-OFF is a simple one-piece construction. The integral cutting edges can be altered upon request for front or back-cutting only. In addition to our standard BURR-OFF tools, custom tools are available upon request. Larger sizes, altered standards, and special designs can be supplied to suit your requirements. Design features : The BURR-OFF is a simple one-piece construction. The integral cutting edges can be altered upon request for front or back-cutting only. In addition to our standard BURR-OFF tools, custom tools are available upon request. Larger sizes, altered standards, and special designs can be supplied to suit your requirements.

...more

Burr Off Tools

The company is a well-reckoned Burr Off Tools Manufacturer, Supplier and Exporter from Tamil Nadu, India. The Burr Off Tools are ruggedly constructed by using the high-grade raw materials and cutting-edge technology in compliance with industry standards. Our Burr Off Tools are known for their higher quality standards, never-failing function and corrosion resistance. Global buyers can avail themselves of ample specifications of Burr Off Tools from us, at cost-effective prices.

...more

Burnishing Tools

Roller Burnishing Tools: Roller burnishing is a cold working process in which highly polished and hardened rollers roll over the surface and high peaks of the surface roughness cold flows into the cavities, thereby imparting smooth surface finish of the order of 0.05 µm Ra and close dimensional tolerance.

...more

Back Spot Facing Tools

The “Back Spot Facing Tools” perform manual or automatic back spot facing and counterboring operations on any type of CNC, Two standard cutters are available from stock: » Cutter designed for front & back chamfering operations. » Cutter designed for front & back-spot facing operations. Advantages: » Save time & mone. » Low Investment. » Compatibility.

...more

back spot facing tool

We have ultra-modern packaging systems available to keep the products safe from physical factors that may damage the product to some extent. Thus, we only use qualitative packaging material. We are hailing from Tamil Nadu(India) and make sure to reach buyer's specific destination within the promised time frame.

...moreBe first to Rate

Rate ThisOpening Hours