Rubber Chevron Conveyor Belt

1,200 - 3,800 Per Meter

500 Meter (MOQ)

APPLICATION Patterned conveyor belt is an inclination conveyor belt composed of Patterned work surface, flat non working surface and core. It is suitable for conveying powder, granular, small pieces materials with the inclination of 0 ~ 40 ° to prevent the material from falling. We often apply it in: conveying bulk material in stone crushing plant, waste recycling plant, sand and gravel aggregate manufacturing plant, thermal power station, concrete mixer plant, mine mining plant, metallurgy plant, port / terminals/ dockside, etc FEATURES 1. There is no joint in belt carcass 2. Long service life 3. Cleats and top cover rubber are vulcanized integrally 3. Cleat pattern, angle and pitch are designed elaborately 4. There are open type and closed type, suitable for bulk or bagged materials such as powder and granule with incline less than 45°. Type Cleat Size (mm) Belt Width (mm) CV, full width Cleat Height=5; 10 Cleat Width= full width Cleat Pitch=100 300-1200 CV, closed Cleat Height=15 Cleat Width=300; 450 Cleat Pitch=250; 300 400-1200 CV, open Cleat Height=15 Cleat Width=385; 600; 750 Cleat Pitch=250 450-1200 CP, open Cleat Height=17 Cleat Width=300; 440; 550; 630; 750; 950 Cleat Pitch=330 400-1400 CP, open & closed Cleat Height=25 Cleat Width=450; 550; 750 Cleat Pitch=330 500-1200 CP, open Cleat Height=32 Cleat Width=580; 630; 750 Cleat Pitch=330 700-1400 U, closed Cleat Height=15; 32 Cleat Width=550; 700 Cleat Pitch=350; 400 650-1200 Multi-V, full width Cleat Height=6 Cleat Width= full belt width Cleat Pitch= 76 500-2000

Rubber Conveyor Belt

800 - 1,500 Per Meter

200 Meter (MOQ)

Best Deals from Rubber Timing Belts

Rubber Conveyor Belts

Get Price Quote

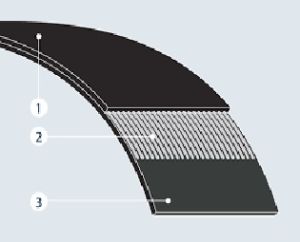

Conveyor belts generally consist of cover rubber, carcass and rubber skim coat. The reinforced breaker fabric is used for extra protection.COVER RUBBER :Covers of natural or synthetic rubber are designed to protect the carcass from -abrasion, impact, deterioration and other injurious influences. They are compounded to meet particular service conditions such as abrasion, oil, heat, fire, chemical resistant and antistatic, etc. CARCASS :Carcass of a belt maintains the belt tension and supplies structural strength; it does all of the work in supporting and pulling the load. Carcass consists of multiple plies of rubber impregnated fabric bonded with friction and skim coats. The fabrics most commonly used are; nylon, polyester and cotton.RUBBER SKIM COAT :Â An extra layer compound between plies that increases flex life and creates a more elastic link so that plies flex without separation. Skim coats cushion fabrics against impact and help protect against moisture. BREAKER FABRIC :A specially woven fabric between the cover and the carcass to improve adhesion and provide better resistance to cover stripping, gouging or tearing. This is normally used in belts handling primarily crushed and sized material which gives great impact to the belt when lumps drop at a loading point. COMPOUND AND USAGE :The cover rubber determines belt life and the selection of the correct cover rubber grade and thickness is most important.HEAT RESISTANT CONVEYOR BELT :In general, it is economical to adopt a heat resistant belt if the temperature of the material to be carried is over 60 C (140 F). As the damage of cover depends on the temperature and nature of transported material, the proper selection of a belt to fit particular operating conditions is important. Especially the relation of temperature between the material and belt surface should be considered when selecting the belt.When transporting material of high temperature of belt surface rises by contact with the material, but on the return journey the heated surface gets cooled naturally by air so that the surface temperature becomes considerably cooler than that of the material. The temperature depends on kind, size, temperature quantity of material to be carried, belt speed, belt length and etc. This belt is designed for transporting cement clinker, cokes, sintered ores, soda ash, chemicals, fertilizer and etc.ABRASION RESISTANT CONVEYOR BELT :Material being carried as well as idlers and frame of the conveyor may cause excessive wearing on normal belts. To prolong the life of the belts running under severe wearing conditions, special and super abrasion rubber is compounded for the belt covers.OIL RESISTANT CONVEYOR BELT :Oily material causes the ordinary rubber covers of the belt to swell and peel off, which results in a complete breakdown in the conveyor system. This belt compounded of oil-resistant -quality synthetic rubber has good resistance to the damaging effects encountered when conveying oil or oily materials. FIRE RESISTANT CONVEYOR BELT :This belt is a prerequisite to prevent fire risks in coal mines where not easily accessible and to reduce maintenance of the conveyors which may be damaged by flame at the blast furnaces of iron works. ANTI-STATIC CONVEYOR BELT :This belt is made especially for use where, for instance in the paper or textile mills, the products being carried stick to the belt surface, or fire risks may be involved due to electro-static sparks.

Rubber Belts

Get Price Quote

Ema Rubber Industries manufactures a range of Rubber Belts. We are leading suppliers of a wide range of Rubber Belts. We offer a selection of Rubber Belts. We are experts in the manufacture of Rubber Belts. Our Rubber Belts are appreciated for its high dimensional accuracy and long service life. Our Rubber Belts perform the best in its class.

Rubber V Belt

50 Per piece

This is the Continental branded v-belts.

Rubber Conveyor Belt

Get Price Quote

1 Nos (MOQ)

Industrial Rubber Belt

Get Price Quote

30 Piece (MOQ)

Rubber Chevron Conveyor Belt

100 - 1,550 Per Pieces

2 Piece(s) (MOQ)

Rubber Conveyor Belt

150,000 Per

industrial rubber belts

1,000 - 1,500 Per Meter

1 piece (MOQ)

We are the leading Suppliers and Exporters of Industrial Rubber Belts in Karnataka, India. We offer them in various sizes and thickness, as per the requirements of the client. Our offered Industrial Rubber Belts are known for their high elasticity, resistance to heat, heavy load bearing capability, durability, and long operational life. We make sure that our offered belts are in accordance with the set industrial standards and norms. We are competent to deliver them in bulk quantities.

Rubber Conveyor Belts

Get Price Quote

We are the Proficiency Importer and Manufacture of Rubber Conveyor Belt in Tamilnadu, India. We have the stock for this conveyor belt to deliver at a punctual time. Our team members produce technically and challenge to make as per customer requirement it Convenient to use all types of Machines. We update and produce this conveyor belt for Different Factories, Different Types of Belts for Various Process, Different Patterns, etc. We Manufacture and Supply for this Conveyor Belt like Cement Factories, Sugar Factories, Stone Plant, Crushing Plant, Coal Plant, Mining Plant, Baggage Handling, Heavy Duty Conveyor Belt, etc. We make the Different Types of Rubber Conveyor Belt like Nylon Rubber Conveyor Belt, Steel Cord Conveyor Belt, Rubber Cleat Conveyor Belt, Polyester Rubber Conveyor Belt, Solid Woven Rubber Conveyor Belt, Normal Rubber Conveyor Belt, Open Nylon Rubber Conveyor Belt, Endless Rubber Conveyor Belt, Heavy Duty Rubber Conveyor Belt, Light Duty Rubber Conveyor Belt, Heat Resistant Rubber Conveyor Belt, Cold Resistant Rubber Conveyor Belt, Fire Resistant Rubber Conveyor Belt, Chemical Substance Rubber Conveyor Belt, Oil Plant Rubber Conveyor Belt, etc. Our Conveyor Belt is mainly used to Transfer Process, Heat Process, Fire Process, Oil Process, Grease Process, Chemical Process, etc. The Buyer like to Choose our Rubber Conveyor Belt like Flexibility to work for Abrasion, High and Low Temperature Process, Best Life Time, Increase production capacity, Save time, Totally Hygiene Components, etc. Specification: We provide different Width, Length and Thickness as per customer requirement.

Packing Machine Rubber Timing Belt

650 Per Piece

100 Piece (MOQ)

Our Timing Belt is available in Red Coating Imported Rubber available in many sizes like : 225L, 60 Teeth, 3/8″ Pitch, W=20mm, 25mm, 30mm as per customer requirement. 240L, 64 Teeth, 3/8″ Pitch, W=20mm, 25mm, 30mm as per customer requirement. 240H, 48 Teeth, 1/2″ Pitch, W=20mm, 25mm, 30mm as per customer requirement Many more size’s (70 Teeth, 72 Teeth, 86 Teeth, 96 Teeth etc.) as per Customer requirement. Timing Pulleys : The Above are only exemplary representations of timing pulley. We can supply tapper lock Bush Pulleys as per customer requirements. Our Pulleys are well accepted OEM as well as End Users. Manufacturing of timing pulleys can only be undertaken after receipt of approved drawing. In case if drawing is not available, we will submit our drawing for approval. The Material Composition of timing pulleys is generally Nylon, Aluminum, Steel or Cast Iron. We can also carry out designing OD new timing belts drive system or conversation of frictional drive system as well as chain and gear drive system to timing belt drive system.

Rubber SHR Grade Conveyor Belt

720 - 2,400 Per Meter

50 Meter (MOQ)

Chemical Resistant Rubber Conveyor Belt

Get Price Quote

Rubber Belts

Get Price Quote

Rubber Conveyor Belts

Get Price Quote

We provide General Purpose Conveyor Belts that are manufactured in accordance to the international quality standards. The General Purpose Conveyor Belts that we present have no alternative available in the market when it comes to high reliability and cost effectiveness. Also, we are one of the distinguished General Purpose Conveyor Belts Manufacturers, exporters, and Suppliers in India. These belts are mainly produced with Rubber cover M-24 and N-17. However we produced General purpose conveyor belts with following rubber cover and properties. Besides this if any customer request his own cover properties the same can also be produced and supplied by us. Applications of General Purpose Conveyor Belts : Crushers, Mining, Coalliers, Thermal Plants, Cement Plants, Steel Plants, Fertilizer plants, Ports, Minerals and Metal Industries etc.

Rubber Conveyor Belt

35,000 Per Piece

5 Piece (MOQ)

Aramide Reinforced Rubber Flat belts

2,000 - 50,000 Per Meter

1 Piece (MOQ)

VSI ENTERPRISES is one of the leading Manufacturers and suppliers of flat belts, Power Transmition flat belts are manufactured with Rubber - Polyester Fabric and Rubber, Our flat belts are work flawlessly during their life span. Power Transmition flat belts Construction: 1) Top Cover for covering or Friction ( Rubber) 2) Core Member is for load carrying (Very High Strength Aramide) 3) Bottom cover is for Friction ( Rubber) Belt Types : GG : both side rubber coating and High Strength Polyester Fabric as Tension Member. Our belts are recognized for quality, reliability, longer life more flexible and higher efficiency. We can run these belts up to 100 M/s speed. Operating temp of this belt is -20°c to + 80 °c and standard width available is 450 mm and we can provide you higher width with special order. Application Area: Textile industries, Pulp & paper industries, Machine tools Automotive Stamping Industries, Paper & printing industries

Rubber Sewing Machine Motor Belt

28 Per piece

100 piece (MOQ)

harvester rubber v belts

Get Price Quote

10 Box (MOQ)