vertical mixer

Manufactured in compliance with international quality accepted standards, Vertical Mixer that we offer is high on demand in the market. Acknowledged for its consistent performance, effectual functioning and longer service life are some of the special features that set our range apart from others. Vertical Mixer is apt for mixing the dry ingredients and not liquids. Presently, we are considered to be a top notch Vertical Mixer Manufacturer, supplier and Exporter from India. Specifications : Vertical shaft that pulls the ingredients to the top and spins itHomogeneous mixHigh mixing efficiencyEfficient greasing system for lubrication of bearingsAccess door provided at the top Components : Two Way Intel HopperAccess Door for Auger RepairingHeavy Auger

...more

Single Shaft Paddle Pre Mixer

Designed with perfection, our company holds specialization in making available to the clients Single Shaft Paddle Pre Mixer. Owing to its robust design, easy operation and trouble free functioning; Single Shaft Paddle Pre Mixer that we provide is widely demanded in both the national and international markets. Specifications : Small paddles mounted on the shaftMixing paddles when rotates push the ingredients from both sides to the centre of Drum.Shaft, cover, drum paddle, etc. are made using SS 304 or SS 316 grade of stainless steel.Mixing Time : 10 - 12 minutes for complete mixingDischarging : For M M-25 model, tilting mechanism to effectively discharge the mixer into collection tankFor MM-50 and MM-100 model, discharge gate is provided at the centre of drum along with rack - pinion arrangement.

...more

Single Shaft Paddle Mixer

Single Shaft Paddle Mixer offered by us, is manufactured according to the set industrials norms and standards. Widely recognized for its supreme quality, high strength and sturdy construction, trouble free performance, Single Shaft Paddle Mixer that we offer is highly demanded in both the national and international markets. Consequently, we are counted amidst most dependable Single Shaft Paddle Mixer Manufacturers, Suppliers and Exporters from India. Specifications : Generates a very homogeneous mixFour curved blades clamped on main shaftFitted with designed oil immersed gear box and mixing paddlesPerfect alignment of gear box ensured by heavy couplingBlades are precisely designed that ensures rapid mixingConstant turbulent movementDifferent Arrangement of fats, liquids or molassesEasy operationResistance to wear and tearBetter bending strengths Demanded By : Feed industry

...more

Single Edge Hammer

Hammer Mill Hammers manufactured by us are widely used in various industries like constructional, steel, Iron and many more. These Hammer Mill Hammers are known for easy to operate functions and have a long working life. Our Hammer Mill Hammers are used to crush materials into fine small particles. Features : Made of special high grade alloy steel and then heat treated to have greater wear resistanceHighly balanced which minimizes the vibration level of your machineHoles are smooth and parallel sides and have close tolerance with hammer rod which gives greater and full width contact area. This reduces hole elongation in hammers and growing in rods

...more

pellet mill dies

we are a leading manufacturer of poultry and cattle feed machines in india. To cater the growing needs of pellet mill spares, particularly dies, we have imported a cnc gun drilling machine from germany in the year 2009 and have been manufacturing and supplying high chrome dies in stainless steel for the last one and half years. We have already become a preferred vender of many feed manufacturing companies in india and abroad. At present, we are supplying these pellet mill dies to more than 60 companies all over india & abroad, including suguna , japfa , uttra , venkys, shrawasthi feeds etc. as far as quality of die is concerned, we can guarantee for our product in material of steel, hole finish, hardness, heat treatment etc. At par with any brand globally. We can provide you testimonials for the same of those who are using these dies. just give our pellet mill dies a try, and we assure you that you will find its performance at par or better than any other brand in world over in total tonnage or product quality. If you are using conventional dies with simple drilling, please go through the details in product brochure for the advantages you will get using our pellet mill dies. For any more information, please contact the under-signed.

...more

Pellet Mill

Pellet Mills use the process in which mixed feed in powder form is converted into pellets by mechanical compression in combination with moisture and heat. In the Pellet Mills this is achieved by a set of rolls and die of suitable hole size and shape. As the die & roll rotate, the product passes through the nip of roll and dies and pressed into die holes to make pellets in the Pellet Mill. Our Pellet Mills are well lubricated to avoid friction and make the process easy and less time consuming. Features : Mechanical compressionCombination of Moisture & Heat Well lubricatedHigh work efficiencyEasy to operateLess maintenance

...more

Pellet Feeder

We Offer Pellet Feeder. The function of Pellet Feeder is to stop, supply & regulate the feed from Pellet bin to Pellet Mill through conditioner. The speed of Pellet Feeder varies by use of A.C. Electronic Variable Frequency Drive. All the parts of Pellet Feeder are made of stainless steel to make them corrosion resistant.

...more

Pellet Feed Plant

Pellet Feed Plant is a place, where, mixed feed in powder form is converted into pellets by mechanical compression in combination with moisture and heat. This is achieved by a set of rolls and die of suitable hole size and shape in the Pellet Feed Plant. Further to this, the Pellet Feed Plant lets the die & roll rotate, here, the product passes through the nip of roll and dies and pressed into die holes to make pellets. Highlights : High compressionProper GrindingMixingSpecific size and shapes of nip

...more

pellet crumbler

We Offer Pellet Crumbler. Crumbling is the process of breaking pellets in small pieces by passing these through rolls rotating at different speeds having grooves on surface. After the hot pellets are cooled to the ambient temperature, the pellets may require breaking into small pieces to feed day-old chicks and grower flock. Pellet Crumbler is equipped with gap adjustment between rolls to get required particle size of feed. In our Pellet Crumbler, one roll is fixed while the other is moveable for gap adjustment. The movable Roll in Pellet Crumbler is spring loaded to protect the rolls from any foreign object coming with feed.

...more

Pellet Counter Flow Cooler

We Offer Pellet Counter Flow Cooler helps to cool the hot pellets coming out from Pellet Mill to ambient temperature to remove excess moisture and heat to improve the shelf life. Pellet Counter Flow Cooler is fast replacing the old cross-flow or horizontal coolers as the Pellet Counter Flow Coolers are compact, maintenance free & highly efficient.

...more

Pellet Conditioner

We Offer Pellet Conditioner. Conditioning is a process in which heat, moisture & liquid is introduced to the feed. The Pellet Conditioner consists of a single or double barrel in which one or two agitators revolve & perform the blending action. The retention time in Pellet Conditioner can be controlled either by varying the speed of the agitator or changing the angle of agitating blades.

...more

Multi Edge Hammer

Hammer Mill Hammers manufactured by us are widely used in various industries like constructional, steel, Iron and many more. These Hammer Mill Hammers are known for easy to operate functions and have a long working life. Our Hammer Mill Hammers are used to crush materials into fine small particles. Features : Made of special high grade alloy steel and then heat treated to have greater wear resistanceHighly balanced which minimizes the vibration level of your machineHoles are smooth and parallel sides and have close tolerance with hammer rod which gives greater and full width contact area. This reduces hole elongation in hammers and growing in rods

...more

Hammer Mill Model No. : FSHM-50120

We are Offering Apt for fine grinding in pelleting operations, we are instrumental in providing in the markets Hammermill Model No. : FSHM-50120. Hammermill Model No. : FSHM-50120 that we offer is suitable to grind 10-12 ton per hour on 3mm hole screen using just 100 hp. Features Quick gap Adjustment between hammer tip to screen to enhance efficiency and quality of grindingAbility to run on 2800 rpm or 1400 rpm as per requirementIdeal for 14-16 MT per hour Mash feed Plant and 10 MT per Hour Pellet Plant.Capable to get fine feed for pelleting and coarse feed for finisher parent flock easily.Manually operated rotor break mechanism to stop the hammer mill immediately without changing the screens that can delay the entire process Specifications Model FSHM 50120Capacity KgsHr. Maize GrindingStarter 4mm8500Grower 5mm10500Finisher 6mm12000Capacity KgsHr.Mixed feed Grinding Starter 4mm12000Grower 5mm14000Finisher 6mm16000Capacity KgsHr.Millet grinding10000Power (H.P.)50-120

...more

Model No: Fshm-3075 Hammer Mill

We Offering to the Clients Hammermill Model No.:fshm-3075, Exclusively Designed for Feed Mills with 8-10 Mthr Mash. this Machine Can Crush 6-8 Mthr On 60 Hp with 3mm Hole Screen. specifications model Fshm 3075 Capacity Kgshr. Maize Grindingstarter 4mm 6000 Grower 5mm 8500 Finisher 6mm 13000 Capacity Kgshr. Mixed Feed Grinding Starter 4mm 8000 Grower 5mm 10000 Finisher 6mm 13000 Capacity Kgshr. Millet Grinding 8000 Power (h.p.)30 - 75

...more

Model No: Fshm-2040 Model No: Fshm-1015 Hammer Mill

We Offer in the National and International Markets Exceptional Quality Hammermill Model No. : Fshm-2040. Runs On 20 to 40 Hp Motor with 4-6 Mthr Mash. Furthermore, this Machine Can Crush 3-4 Mthr On 40 Hp with 3mm Hole Screen for Pelleting Operations. specifications model Fshm 2040 Capacity Kgshr. Maize Grindingstarter 4mm 4500 Grower 5mm 6500 Finisher 6mm 9000 Capacity Kgshr. Mixed Feed Grinding Starter 4mm 6500 Grower 5mm 8500 Finisher 6mm 11000 Capacity Kgshr. Millet Grinding 4500 Power (h.p.)20 – 40

...more

Model No: Fshm-1015 Hammer Mill

We Offer Hammermill Model No.: Fshm-1015, Especially Designed for Small Feed Mills. Runs On 10hp Motor and Renders Effective Results of Grinding. Hammermill Model No.: Fshm-1015 Offered By Us Can Be Changed from Normal Grinding to Coarse Grinding as per Your Requirements. We also Provide Outlet Hopper, Inlet Hopper and Vibration Dampers Along with this Model. specifications model Fshm 1015 Capacity Kgshr. Maize Grindingstarter 4mm1800grower 5mm3200finisher 6mm4000capacity Kgshr.mixed Feed Grinding Starter 4mm2500grower 5mm4000finisher 6mm5500capacity Kgshr.millet Grinding1800power (h.p.)10 – 15

...more

Mash Feed Plant

Mash Feed Plant is designed for consistent output at all stages. The grinding process in Mash Feed Plant gives uniform texture. During the mixing process in Mash Feed Plant, the mixing is accurate and takes less time. All the machines of Mash Feed Plant are in matching capacity. Our Mash Feed Plant is known for minimum power consumption and needs little to no maintenance. Features : Low maintenanceFine grindingProper mixingAccurate and less time consuming

...more

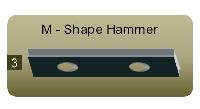

M Shape Hammer

Hammer Mill Hammers manufactured by us are widely used in various industries like constructional, steel, Iron and many more. These Hammer Mill Hammers are known for easy to operate functions and have a long working life. Our Hammer Mill Hammers are used to crush materials into fine small particles. Features : Made of special high grade alloy steel and then heat treated to have greater wear resistanceHighly balanced which minimizes the vibration level of your machineHoles are smooth and parallel sides and have close tolerance with hammer rod which gives greater and full width contact area. This reduces hole elongation in hammers and growing in rods

...more

Industrial Mixer

Industrial Mixer is considered a very important part in the feed milling operation. The proper mixing by the Industrial Mixer is very important to get the required nutritional value for the animals. Our Industrial Mixer meets the regulatory guidelines of food and drug administration. These Industrial Mixers are less power consuming and require no maintenance. The Industrial Mixers are used in many industries like Chemical, Fertilizers, Constructional and many more. Our main motive with the Industrial Mixer is to create a completely homogeneous blend. Highlights : Robust structureEasy to operateLow maintenanceOutput driven system

...more

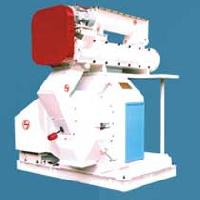

Horizontal Pellet Mill

We are considered to be one of the leading Horizontal Pellet Mill Manufacturers, Suppliers and Exporters from India. Owing to its effectual functioning and smooth operation, Horizontal Pellet Mill offered by us is widely acclaimed in the national and international markets. Avail from us Horizontal Pellet Mill at most economical prices. Attributes : Unmatched quality oil seals provided with hardened wear sleevesEasy to handleHigh energy efficiencyRobust knife design with stainless post & carbide knife tipReliable performanceUser friendly operationHeavy duty self aligning spherical roller bearings Benefits of Pelleting : Minimum feed wastageReduces ingredients segregationIncreases bulk densityDecreases selective feedingLess time and energy expended on prehensionThermal modification of starch and proteinImproves palatabilityDestruction of pathogenic organism

...more

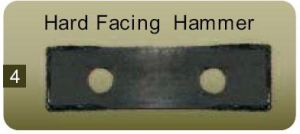

Hard Facing Hammer

Hammer Mill Hammers manufactured by us are widely used in various industries like constructional, steel, Iron and many more. These Hammer Mill Hammers are known for easy to operate functions and have a long working life. Our Hammer Mill Hammers are used to crush materials into fine small particles. Features : Made of special high grade alloy steel and then heat treated to have greater wear resistanceHighly balanced which minimizes the vibration level of your machineHoles are smooth and parallel sides and have close tolerance with hammer rod which gives greater and full width contact area. This reduces hole elongation in hammers and growing in rods

...more

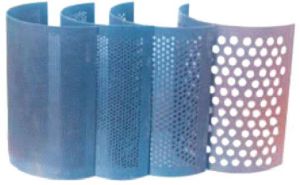

Hammer Mill Screens

Our Hammer Mill Screens have greater opening area which is achieved by more number of holes per unit area and strength & life is achieved by providing more thickness to screens. It is a fact that if we use 1.5 times thicker screen, we will get 3 times more life. By increasing the thickness of Hammer Mill Screens there is one more change, we will get much finer material on same hole which is particularly beneficial in grinding for pelleting operation. We also offer customization of Hammer Mill Screens. Features : Easy to operateLong working lifeCorrosion resistantLow maintenance

...more

hammer mill parts

half screen hammer mill

Leveraging our rich experience, we make available to the clients Half Screen Hammer Mill. Half Screen Hammer Mill is highly beneficial for decreasing the particle size of various ingredients in the feed. Changing the screens of several hole sizes in the grinder allows excellent grinding result. Components : Round shaped highly balanced rotor with only minimum vibration and when motor works at a high speed strikes with the materials and break themNo leakage of material between screen and body of grinderSpecially designed hinges which do not loose throughout its lifeDetachable stripSpecially designed outlet which facilitates free flowing of ground ingredients into bag while baggingRenovated inlet hopper design, to let not the material fall down by sidesTo protect dust from entering the bearings, Bearing brackets are fitted at some distance from bodyProvided with a Belt safety cover Benefits : Enhance mixing characteristic of ingredients.Improves pellet quality and Pelleting efficiencyEnsures easy handling of ingredientsReduce particle size to assure easy digestion of ingredients by animal Attributes : Robust constructionEffectual functioningConsistent performanceLow maintenance costLonger service life Technical Specifications ModelCapacity / Hr. Maize GrindingCapacity / Hr. Mixed Feed GrindingCapacity / Hr. Millet GrindingPowerStarterGrowerFinisherStarterGrowerFinisherLG-1 150 kgs 300kgs 500kgs 250kgs 500kgs 650kgs 200kgs 3 H.P.LG-2 500 kgs 1000kgs 1300kgs 800kgs 1500kgs 2000kgs 500kgs 5 H.P.LG-3 1000 kgs 1500kgs 2500kgs 2000kgs 3000kgs 4000kgs 800kgs 10 H.P.LG-4 1500 kgs 2500kgs 4000kgs 2500kgs 3500kgs 6000kgs 2200kgs 20 H.P.

...moreBe first to Rate

Rate ThisOpening Hours