Welding Metallurgy Courses

Get Price Quote

This course is mainly for personnel in Production, QA, Maintenance and purchase functions. Minimum qualification Science graduate/ Diploma/ Degree in Engineering.The course covers various welding techniques in brief and more in detail on Metallurgy at Weld joint. How the heating and cooling of material at weld joint behave, What property changes occur and how to control metallurgical properties of weld joint are discussed.Next step Register for the course by filling up following details. (as per attachment). Attend course and get certificate Course Fee Per person₹3000 / US $ 40

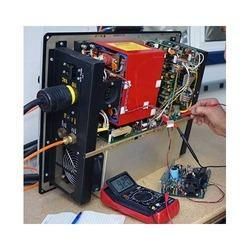

Ultrasonic Plastic Welding Machine Repairing Services

Get Price Quote

Are you looking for professional and cost-effective Ultrasonic Plastic Welding Machine Repairing Services? If yes, we at D K Machine Services are here to give you the right assistance. Backed by years of experience in Machine Repairing Services, we have been able to offer the best collection of services. Our services rightly follow up the guidelines of the industry. Moreover, we are familiar with the latest techniques that assist us to give the best services to clients in the most appropriate way. We focus more on customer satisfaction through Quality Products & Services Driven by a team of experts with passionate dreams.

Looking for Welding Services Providers

Welding Inspection Mirrors

Get Price Quote

welding inspection mirrors. High quality and durable welding inspection Mirrors from Ullman - USA are known for their seemingly limitless uses both around the home and in the shop. For instance, an magnetic pick-up tool telescopic inspection mirror can be used to check behind an armoire for lost keys or beneath an engine block for a missing bolt. Welding Inspection Mirrors are popular for welding inspection as gives precise information about weld. Welding Inspection Mirrors come in a variety sizes and lengths, and feature dual ball-and-socket joints for infinite angle adjustments of the mirror. These telescopic welding inspection mirror has extension to reach long. All types of Inspection Mirrors rectangular, oval or rectangular and also magnetic pick sticks are also supplied in India and abroad.

300amps rilon arc welding machine

12,000 Per Unit

1 Unit (MOQ)

Mosfet technology,the core adopts advanced Mosfet inverter device. Wide range for input voltage:380V±15%. Digital meter to preset and display welding current. Dust-Free Cooling Systerm with Upgraded Duty Cycle. ARC force and Hot start adjustable, easy to striking the arc. Auto-Protection against over-voltage, over-current and over-heated. Remote control function(optional), enlarge your welding Area,easy to operate. Energy Saving - More efficient compared with the traditional SCR machine Arc-Force for Anti-Sticking Hot-Start to start the Welding Arc Smoothly Remote-Control Function Optional. Wide Range for Input Voltage: 380 +- 15% Dust-Free Cooling System with Upgraded Duty Cycle With Advanced Single IGBT Technology

mig welding services

Get Price Quote

MIG Welding Services provide reliable and efficient metal joining solutions for various industries, including automotive, construction, and manufacturing. Using the Metal Inert Gas (MIG) welding technique, these services ensure strong, high-quality welds on materials such as steel, aluminum, and stainless steel. MIG welding offers advantages like high welding speed, ease of automation, and the ability to weld thin and thick materials with precision. Ideal for both production and repair work, MIG welding services deliver consistent, clean, and durable joints. These services are essential for creating robust metal structures, assemblies, and components, enhancing overall manufacturing efficiency and product quality.

Robotic CO2 Welding Services

Get Price Quote

Our Robotic CO2 Welding Service offers cutting-edge automation for precise, efficient, and cost-effective welding solutions. Utilizing state-of-the-art robotic systems, we ensure high-quality welds across diverse materials and configurations. Our skilled technicians guarantee adherence to industry standards, emphasizing safety and flexibility. From customized projects to large-scale production, we provide fast, reliable, and environmentally conscious robotic CO2 welding services, optimizing productivity and minimizing costs for our valued clients.

laser welding service

Get Price Quote

Revolutionize your metal joining needs with our advanced laser welding service. Our state-of-the-art technology ensures precision and efficiency, producing immaculate welds in diverse materials. From intricate designs to heavy-duty applications, our skilled technicians deliver unmatched quality and speed. Benefit from minimal heat-affected zones, reduced distortion, and superior control, resulting in stronger and more durable welds. We cater to various industries, guaranteeing reliable solutions for your specific requirements. Trust our expertise for cost-effective, timely, and innovative laser welding services that elevate your projects to new heights. Experience the future of welding with our cutting-edge solutions.

Excavator Buckets Welding Services

Get Price Quote

We provide welding of excavator buckets. Life of excavator buckets can be extended by providing a ling of wear resistant manganese steel strips. We also carry out repairs to damaged buckets used for soil excavation and rock cutting. Welding is done using co2 welding machine which gives good bond between parent material and new material.

Jigs and Fixtures Welding Services

Get Price Quote

UMS understand the jigs and fixtures as your production tools used to accurately manufacture duplicate and interchangeable parts. UMS jigs and fixtures are specially designed so that large numbers of components can be machined or assembled. It help in the machining of jobs and reduce the human efforts required for producing parts & components. Types of fixtures UMS works on are Turning, Milling, Broaching, Grinding, Boring, Tapping, Duplex & Welding Fixtures. Different objects require different treatments like drilling, milling, planing, grinding machines, etc. Specific tools are necessary for producing these objects in identical shapes and sizes on a mass scale by holding and locating tasks to minimize the repetition work. Special Jigs & Fixtures Customized Jigs & Fixtures Innovative Jigs & Fixtures Wielding for Jigs & Fixtures

Aluminum Welding Services

2,500 - 3,500 Per No

Aluminium and its Alloys Aluminium is a chemical element, which makes up about 8% of the Earth’s crust, making it the most abundant metal and the third most abundant element after oxygen and silicon. Aluminium is well known for having a low density (about 2.7 g/cm3) and, through the phenomenon of passivation, excellent corrosion resistance. As pure aluminium is relatively soft, small amounts of alloying elements are added to produce a range of mechanical properties. The alloys are grouped according to the principal alloying elements. Specific commercial alloys have a four-digit designation according to the international specifications for wrought alloys or the ISO alpha-numeric system. Table 1 provides further details on the make up of these classifications. The first digit of the series indicates the principal alloying element added to the aluminium alloy and is used to describe the series, i.e. 1000 series or 5000 series, etc. The second digit represents the modification of the specific alloy within the series; i.e. x1xx represents the first modification to the specified alloy, while x2xx represents the second modification. The third and fourth digits identify the alloy within a specific series. To summarise, alloy 2024, is in the 2000 series of alloys, has zero modifications and is specified alloy type 24. There is, however, an exception to this numbering system and that is for 1000 series aluminium; the last two digits provide the minimum aluminium percentage above 99%. For example, 1050 means 99.50% minimum aluminium content. Aluminium alloys will also include a temper designation, these define additional processing steps (if implemented). The temper designations are detailed in table 2. Further to the basic temper designations detailed in table 2, there are two sub-designations for ‘H’ – strain hardening, and ‘T’ – thermally treated. Table 3 and 4 describe these ‘H’ and ‘T’ designations, respectively.

Orbital Welding Services

Get Price Quote

In Orbital Welding Services an inert gas welding is used which eliminates odds of manual errors in welding since it yields similar welds for hundreds of times hence accuracy in welding.

Manual Welding Fixture Designing Service

Get Price Quote

Our Manual Welding Fixture Designing Service specializes in creating precise, durable, and efficient welding fixtures tailored to your specific needs. With a focus on accuracy and functionality, our fixtures ensure seamless alignment and support for your welding operations, boosting productivity and quality. Backed by advanced tools and experienced professionals, we deliver solutions that meet industry standards while optimizing your production workflow. Whether for automotive, industrial, or custom applications, our designs cater to varied requirements, ensuring reliability and ease of use. Trust us for innovative and cost-effective manual welding fixture solutions that enhance your manufacturing efficiency.

Stainless Steel Argon Welding Services

Get Price Quote

Welding Services

Get Price Quote

Process Overview – Welding is a process of joining metals or thermoplastics by using a high amount of heat generated by a power source. This melts the material to fuse together and form a metallurgical bond which is protected by a shielding inert gas to prevent contamination and oxidation. Few commonly known welding services offered by us include GMAW (Gas Metal Arc Welding), GTAW (Gas Tungsten Arc Welding), SMAW (Shielded Metal Arc Welding), FCAW (Flux Cored Arc Welding) and Laser Welding. While this technology has long been used for joining metals, we also utilize it for overlaying specific alloys on carbon steel and stainless-steel substrate to impart enhanced properties. Our main expertise in this area include : GTAW – It utilizes a non-consumable tungsten electrode to produce the weld when a filler wire is introduced in the arc protected by a shielding gas. It produces a homogeneous and low dilution metallurgical bond with the base metal substrate and mainly used for deposition of Stainless Steel and its alloys, Nickel, and its variants, Stellite and its variants. Weld overlay followed by PWHT (Post Weld Heat Treatment) makes the welding denser and removes any residual stresses induced by the welding. PTA – Plasma Transferred Arc is a process used to fuse a metallic coating to a substrate to improve its resistance against wear and/or corrosion. Metal powder is fed into a molten weld puddle (fusion bath) generated by the plasma arc at high temperature (up to 20,000 °C). Deposit thickness can range from 0.6 to 6.0 mm, width from 3 to 10 mm when using a single pass; multi pass welding reaches deposit thickness up 20 mm and width over 30 mm. The deposit microstructure is dense with formation of dendrites during solidification. One of the most important features of the PTA process is the control of dilution which is as low as 5%. It is usually preferred for overlaying of exotic materials such as Nickel and its variants and Stellite and its variants. Spray and Fuse - It is an extension of coatings done by Powder Flame Spray process wherein the sprayed coating is fused with the base material by application of external heat energy using Oxy-Acetylene torch, Induction coil, Furnace, Laser beam or an external heating source. The coating is taken to solidus temperature (1020 to 1100°C) at which the coating fuses and voids and porosity in the coating collapses making the coating denser and more homogeneous. This also forms a fine metallurgical bond with the prepared substrate which makes the coating capable of enduring impacts. A variety of materials can be deposited by this process to achieve properties required for different critical applications such as Cobalt and its variants, Nickel and its variants, Carbide and its variants etc. Laser Cladding - It is the use of electrically produced laser light to heat wire or powder material and apply it to a substrate surface. Since the heat input generated by laser is less it produces minimal HAZ (Heat Affected Zone) which is detrimental to the weld quality. Laser cladding is often performed by robotic manipulators and produces a very dense and homogeneous deposit with the least amount of dilution. Vacuum Brazing – It is a process of joining two similar or dissimilar metals by heating a braze alloy between the components inside a vacuum furnace. The braze alloy has a lower melting temperature than the parent component and melts easily to fill the clearance and form a joint. Vacuum Brazing is preferred where leak tight joints are required mainly in critical Aerospace and Defence components, Automotive and HVAC industries. We specialize in vacuum brazing of nickel and aluminium based filler metals which are available in the form of paste, wire, and foil. Capabilities Latest weld overlay and laser cladding technology Weld overlay facility integrated with heavy engineering tool room Welding and Cladding processes available – GTAW, PTAW, SMAW, FCAW and Laser. Welding and Laser cladding of exotic materials such as Nickel and its variants, Cobalt and its variants, Carbide and its variants etc. Completely automated welding setup capable of welding parts up to 2000mm Dia and 2000mm long Pre and post machining of weld overlayed parts up to 1500mm Dia and 6000mm long Grinding of weld overlayed parts up to 800mm Dia and 6000mm long Heat treatment furnaces for pre and post coated/welded parts up to 2000mm Dia and 8000mm long Complete end to end manufacturing of weld overlayed/cladded parts and assemblies Dedicated welding setup for batch and production parts Qualified welding operators capable of manual as well as semi-automatic welding Availability of WPS, PQR and WPQ for range of materials qualified by internationally recognized certifying bodies NADCAP certified High Vacuum Brazing furnaces for Aerospace and Automotive parts In-house laboratory for microstructure analysis of welded samples including micro-hardness and bond strength evaluation Welding facility certified to AS 9100 Rev.D and ISO 9001 Quality Management System Welding shop approved by BHEL and MNC’s such as Siemens and L&T Application and Benefits Like plating and coatings, weld overlay finds applications in critical working environments such as Oil & Gas, Steel, Pumps and Valves, Hydraulic, Plastic Extrusion etc. Few commonly welded overlaid parts include valve spindles, diffusers, shafts, pump casings and rings, mandrels and housings, piston rods etc. Weld overlay and Laser cladding offer numerous advantages such as : Wide range of exotic materials can be used in different forms Flexibility to apply on any base material substrate Forms a metallurgical bond which gives high impact strength Enhances wear, abrasion, corrosion, and high temperature oxidation resistance Improves operational life of part Reduces downtime and breakdown costs

Pipeline Welding Services

Get Price Quote

AYYAPPA GEOSYNTHETICS INSTALLERS capable of managing all fabrication for HDPE and PP pipe solution including the design, engineering certification, fabrication, construction, installation and commissioning.We fabricate from install HDPE liners, and complete minor civil works. Works range from emergency repairs, shutdowns, and maintenance upgrades through to complete HDPE piping systems installations.All welding for HDPE piping systems is performed in accordance with thoroughly developed quality standards, with all weld parameters calculated and recorded on weld logs and all worked performed in safety management system.We use state of the art welding equipment which reduces manpower requirements on site and improves productivity.AGI also carries a large range of pipe and fittings, including stubs, backing rings, reducers, bends, tee pieces, valves, gaskets and bolts – all available off the shelf – in sizes from 32mm to 630mm. This enables us to deal with our customers emergency needs promptly, avoiding costly delays.Applications Welding of HDPE Pipes. Floatation, Shifting and Sinking of Pipe Lines. Installation of Pipe Line on Sea Bed. Head works and generator installations Complete pipeline welding and installation Valve installations Testing and commissioning Operate and maintenance The Ranges of Varied Dimensions of Hdpe Welding Machines are Like 63-160 mm 90-315 mm 315-630 mm

Welding Machine Service

10 - 100 Per Piece

10 Piece (MOQ)

Is your welding machine acting up? Don't risk a halted project! Our certified technicians offer comprehensive welding machine service to keep your equipment running smoothly. We service all major brands of MIG, TIG, and stick welders. From routine maintenance to in-depth repairs, we diagnose and fix issues quickly and efficiently. We use genuine parts and prioritize safety, ensuring your machine operates at peak performance and complies with safety standards. Minimize downtime and maximize productivity. Schedule your welding machine service today! We offer flexible appointment options and competitive rates. Get back to creating strong, reliable welds with confidence.

welding automation system

25,000 Per Piece

1 Piece (MOQ)

Welding SPM Automation: Customized Solutions for Superior Performance At INNOVIC, we specialize in providing advanced welding SPM (Special Purpose Machine) automation solutions tailored to meet the unique needs of our clients across various industries. With a commitment to innovation and quality, we take pride in designing and manufacturing customized welding automation systems that enhance productivity and efficiency in fabrication processes. Our Expertise in Welding Automation: Tailored Solutions: Customization is a key driving force behind INNOVIC's success. We recognize that every project presents unique challenges, and our team excels in creating bespoke welding automation solutions. From the initial design concept to final manufacturing, we ensure our systems align with the specific requirements of each client. Comprehensive Understanding: Our in-depth knowledge of welding processes and technologies enables us to provide world-class solutions. We collaborate closely with clients to assess their operational challenges and develop effective automation strategies that optimize performance and reduce cycle times. Professional Approach: At INNOVIC, we are dedicated to delivering ultimate welding solutions with a professional, customer-centric approach. Our team of experts ensures that clients receive high-quality, reliable, and efficient automation equipment that enhances their production capabilities. Innovation and Reliability: Our welding SPM automation systems incorporate the latest technology and engineering practices, ensuring they are both innovative and reliable. This commitment to quality has positioned us as a preferred supplier in the welding automation market. Industry Applications: Our solutions cater to a wide range of industries, including automotive, aerospace, construction, and heavy manufacturing. Whether it’s for spot welding, MIG/MAG welding, or specialized welding applications, we provide the equipment and support needed for success. Achieve Greater Efficiency with INNOVIC Welding SPM Automation: By choosing INNOVIC for your welding automation needs, you are investing in systems designed to enhance productivity, improve weld quality, and streamline manufacturing processes. Our dedication to customer satisfaction and technological advancement positions us as a leader in the welding automation sector.

Welding Services

Get Price Quote

Custom Welding and Fabrication Services

Get Price Quote

SSV Vessels fabrication division handles a wide range of custom fabrication projects including conveyors, Hoppers, Manifolds, Skids and other complex equipments that are specific to your application. Our skilled & experienced team uses the latest in welding and fabrication technology to bring you perfect pieces every time. Structural Fabrication SSV Vessels handles the building of all structural steel projects. All of our structural products are designed with safety in mind and rated to meet your load and weight requirements. Heavy Fabrication SSV is capable of large scale custom metal fabrication projects of any size including industrial structure, large capacity water storage tanks and more. Finishing Whether its Blasting, Painting or Powder Coating you want, SSV Vessels Private Limited has all the technological know-how to satisfactorily provide cost effective and durable solutions to provide surface protection solution to our clients.

Cobalt welding service in Bangalore

Get Price Quote

1 Inch (MOQ)

Titanium, Monel, Hastelloy, Inconel, Nickel, Magnesium, Tungsten, Molybdenum, Tantalum, Cobalt, Niobium, Nimonic, Nichrome Wire, High Nickel Alloys, Stainless Steel, Copper, Aluminium & much more..all types welding service in Bangalore

welding certification service

Get Price Quote

Preparation of PWPS, PQR, WPS. Services Welding Qualifications Trainings and Certification Services Welding Processes SMAW,GTAW,GMAW,FCAW Training services Maintenance and Repair Welding Training and Services. Welding Documentation Services

Welding Generator Repairing Services

Get Price Quote

Welding Certification Services

Get Price Quote

Our company specializes in offering Welding Certification Services. We have experience of offering training and Welding qualification tests for gaining Welding Certification. We conduct pre-employment screenings to ensure that the welder can weld up to the company’s standards. Our Welding certifications tests are designed to make sure the welder’s skills are up to the code they will be working for. Interested ones can contact us any time. More About Welding Certification Services : Welding certifications are also documented to prove that the welder is qualified under that code. Welding codes vary a lot depending on the type of work being done. Many organizations have different procedures depending on the type of work they oversee.

Stud Welding services

Get Price Quote

Getting the stud welding services is an affordable option when compared to owning a stud welding machine, especially when bulk stud welding is not involved. Sarthak Fabrication is a reliable destination in Nashik (Maharashtra) from where the clients can avail cost-effective yet robust solutions for stud welding. The studs welded by us gain a firm grip on the metallic surfaces, thus providing longer service in respective applications.

Warpp Welding Machine Repairing Services

Get Price Quote

We have gained expertise in providing premium Warpp Welding Machine Repairing Services to our esteemed customers. We are backed by a team of dexterous professionals who have comprehensive knowledge in this field. We enhance customer satisfaction checking the machine on various parameters and ensuring each components optimal function. This results in an improved performance of the system, reducing its operational expenditure. The affordable rates and prompt project completion has made us a reliable Warpp Welding Machine Repairing Services provider from Kolhapur, Maharashtra.

welding consultancy services

Get Price Quote

Sekar Engineering Works is a renowned company providing welding consultancy services around the country. We all are aware that it’s very important to take into consideration the weld design, processing of material, metallurgy, fabrication, repair, and quality control in hand before the welding construction and the guidance of the professional especially for the large task is essential. We have an exceptional team of professionals with vast experience in the field. We give special attention to the quality we provide and move earth and sky for the satisfaction of our clientele. Our services are very reasonably charged and are extremely convenient to avail. However, one can contact us for more details regarding the services.

Welding Procedure Specifications

Get Price Quote

Weld Testing, Inspection and Failure Analysis Mett-Bio Metallurgical Testing & Services offers verities of weld tests to its manufacturing clients. MettBio offers Third party weld test, welder qualification cervices for welder certification and welding procedure qualification. Our scope includes: Welder Qualification (AWS) Testing for performance qualification and welder certification Preparation of Welding Procedure Qualification (AWS) as per client or project requirements Documentation of the Welding Procedure Qualification in a Certified Test Report Coupon Testing as per Welding Procedure Qualification which includes visual examination, mechanical testing, metallographic examination and non-destructive testing Typical weld test performed includes: Macroetch examination Hardness Testing Ferrite examination Corrosion Testing Non Destructive Testing

Welding Railway Vehicles EN 15085-2 Certification Services

2,000 - 100,000 Per Certificate

Railway vehicles EN 15085:2007 - with respect to the railway environment the standard series EN 15085:2007 specifies certification and quality requirements placed on the manufacturers that use welding in connection with the manufacturing of new structures and in connection with repairs. The standard series provides interconnection between output requirements specified for the structure, inevitability to have adequate quality of weldments in the course of the manufacturing process and the subsequent applications of the required types of quality control in production. Welding railway vehicles EN 15085-2: Railway application – welding railway vehicles and their parts - Part 2: Requirements concerning quality and certification of the manufacturer in connection with welding. The series of standards apply to the welding of metal material in connection with the manufacturing and maintenance of railway vehicles and their parts, specify certification levels and requirements concerning manufacturers as regards welding, and describe verification procedures to be used by manufacturers in the welding processes. Necessary classification within EN 15085-2:2007 Kind of product in relation to the certification level - four certification levels (CL) (levels 1 to 4) are specified for certification of the manufacturer. Particular certification levels further specify corresponding classes of weldment execution (CP A - CP D) of welded joints specified in EN 15085-3:2007. Certification levels: CL 1 - this level applies to the manufacturers that produce welded parts of railway vehicles or their welded parts with welded joints with the class of weldment execution CP A to CP D (certification level Cl 2 and CL 4 is involved). CL 2 - this level applies to the manufacturers that produce welded parts of railway vehicles with welded joints with the class of weldment execution CP C2 to CP D (welded joints classified with the class of execution CP C1 are involved if these weldments are checked in accordance with the check class CT 1). CL 3 - this level applies to the manufacturers that produce welded parts of railway vehicles with welded joints with the class of weldment execution CP D. CL 4 - this level applies to the manufacturers that do not weld railway vehicles or their parts but that design or purchase railway vehicles and their sets or distribute them (certification for welding work is not required as regards certification level CL 3). Class of weldment quality – must be determined at the phase of the design depending on the safety category and the category of stress, practicability and feasibility of weldment is important. Welded joints are divided into six classes of weldment execution (CP A, CP B, CP C1, CP C2, CP C3, CP D), which are directly related to the class of we?dment testing and checking. EN 15085:2008 as a profile of manufacturer Marketing and management system of railway vehicle welding production - marketing established requirements concerning the quality management system within welding processes. For that reason it is important to know what the client thinks of the quality of welding operations. There is a number of fields where the supplier can only meet the requirements made by product standards, however it is necessary to take into account that according to the client the quality is not only the utility properties of a product, however the client assesses also the quality of related logistic, production supporting and production processes as well as other ways of communication in connection with the final provision of the order.

Welding Services

Get Price Quote

Consider our name if you are looking for a dependable name that can fulfil your welding requirements in a seamless manner. With our services, we liaise with clients, understand their requirements and provide welding solutions accordingly. At Galaxy Fire Safety System, we make use of modern-day welding tools and equipment for completing the undertaken welding task. Over the years, we have acquired excellence, thus we can be relied for all sorts of welding requirements. We are based in Hyderabad (Telangana, India) and can be contacted for detailed discussion.

Welding Transformer Repairing Service

Get Price Quote

Located in Standard Electricals Vadodara (Gujarat, India) is a prominent name, which is widely known for providing the clients with top-class welding transformer repairing services. Working for us is a group of astute welding transformer technicians, who hold expertise in repairing any kind of defaults and bugs in the welding transformer in a quick manner. For any query, you can contact us at our numbers that are available on our official website.